Subaru Crosstrek Service Manual: Removal

CONTROL SYSTEMS > MT Gear Shift Lever

REMOVAL

1. Disconnect the ground cable from battery. NOTE">

NOTE:

For model with battery sensor, disconnect the ground terminal from battery sensor.

2. Remove the console box. Console Box > REMOVAL">

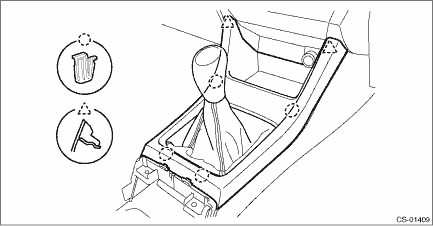

3. Remove the gear shift knob and remove the cover - shift lever.

4. Remove the panel center LWR LH and RH. Console Box > REMOVAL">

5. Remove the clamp.

6. Remove the boot and insulator assembly.

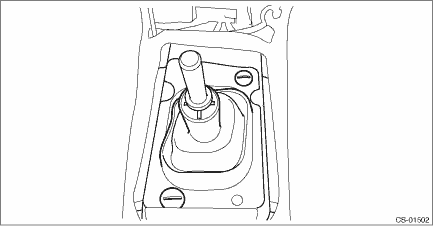

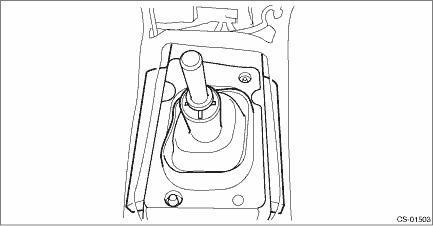

7. Remove the harness clamp from the plate COMPL.

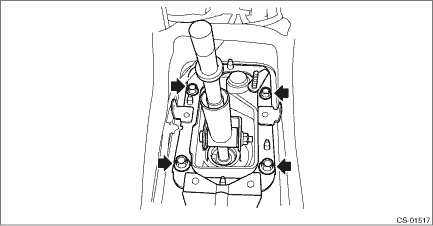

8. Remove the plate COMPL from the vehicle body.

9. Lift up the vehicle.

10. Remove the center exhaust pipe. Center Exhaust Pipe > REMOVAL">

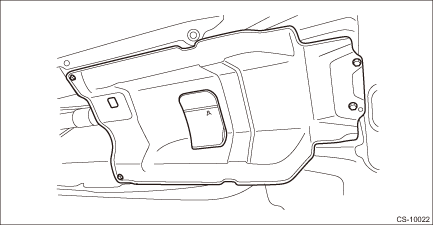

11. Remove the center exhaust cover.

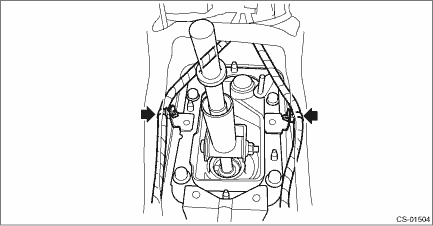

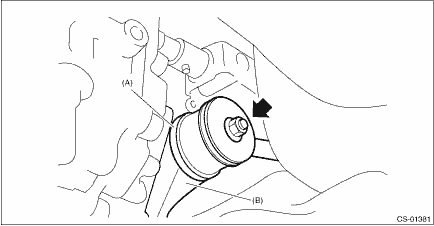

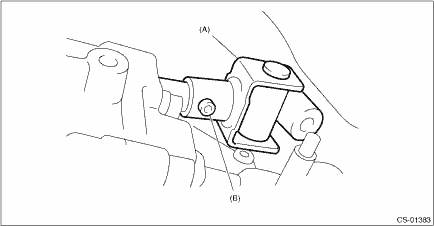

12. Remove the stay from the shift bracket.

(A) | Stay |

(B) | Shift bracket |

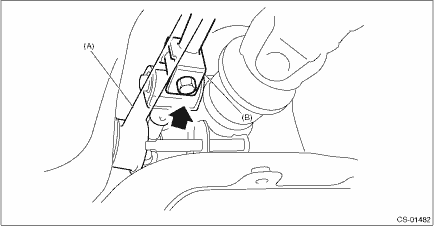

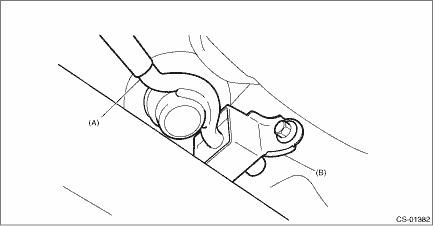

13. Remove the rod from joint.

(A) | Stay |

(B) | Rod |

14. Remove the cushion rubber from the vehicle body.

(A) | Stay |

(B) | Cushion rubber |

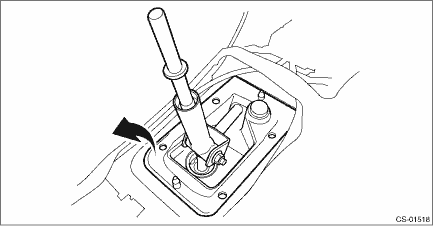

15. Extract the spring pin and remove the joint.

(A) | Joint |

(B) | Spring pin |

16. Lower the vehicle.

17. Remove the gear shift lever.

Assembly

Assembly

CONTROL SYSTEMS > MT Gear Shift LeverASSEMBLYNOTE:• Clean all the parts before assembly.• Apply NIGTIGHT LYW No. 2 grease or equivalent to each part. General Description > COMPONENT ...

Disassembly

Disassembly

CONTROL SYSTEMS > MT Gear Shift LeverDISASSEMBLY1. Remove the lock wires.(A)Lock wire2. Remove the rod from gear shift lever.(A)Rod(B)Lever(C)Stay3. Separate the rod and inner boot.4. Remove the sn ...

Other materials:

Subaru select monitor Operation

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Subaru Select MonitorOPERATION1. HOW TO USE SUBARU SELECT MONITORFor detailed operation procedures, refer to “Application help”.2. READ CURRENT DATA1. On «Start» display, select «Diagnosis».2. On «Vehicle selection» display, inp ...

Removal

LIGHTING SYSTEM > Front Turn Signal Light BulbREMOVAL1. Disconnect the ground cable from battery. NOTE">2. Turn the steering wheel in the opposite direction from the parts to be removed. Then remove the clips and turn over the mud guard - front.3. Remove the bulb socket and front turn si ...

Registration

For example, to register "32468" as the

PIN code, perform the following procedure.

1. Press the rear lock button three times.

2. After a buzzer (ding) sounds once,

press the rear lock button twice.

3. After a buzzer (ding) sounds once,

press the rear lock button four times.

4. After a ...