Subaru Crosstrek Service Manual: Component

CLUTCH SYSTEM > General Description

COMPONENT

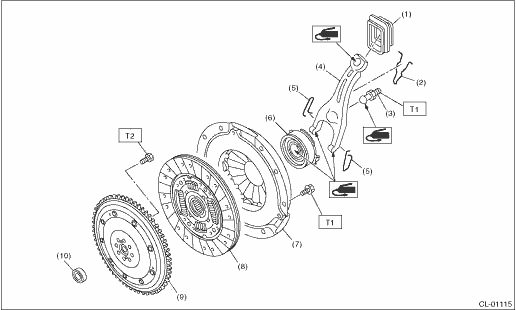

1. CLUTCH ASSEMBLY

(1) | Dust cover | (6) | Release bearing | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Lever spring | (7) | Clutch cover | T1: | 16 (1.6, 11.8) |

(3) | Pivot | (8) | Clutch disc | T2: | Flywheel > INSTALLATION"> |

(4) | Release lever | (9) | Flexible flywheel | ||

(5) | Clip | (10) | Pilot bearing | ||

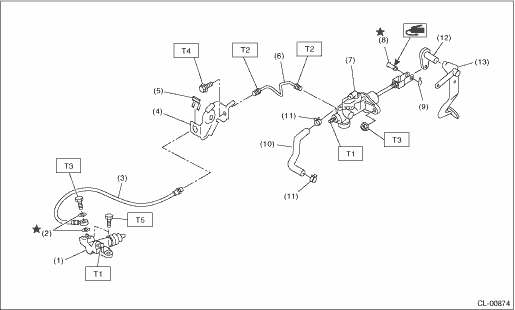

2. CLUTCH PIPE AND HOSE

(1) | Operating cylinder | (8) | Clevis pin | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Gasket | (9) | Snap pin | T1: | 7.8 (0.8, 5.8) |

(3) | Clutch hose | (10) | Tank hose | T2: | 15 (1.5, 11.1) |

(4) | Clutch hose bracket | (11) | Clamp | T3: | 18 (1.8, 13.3) |

(5) | Clamp | (12) | Lever | T4: | 25 (2.5, 18.4) |

(6) | Clutch pipe | (13) | Pedal | T5: | 37 (3.8, 27.3) |

(7) | Master cylinder ASSY | ||||

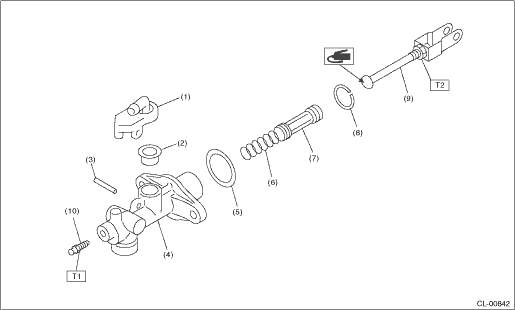

3. MASTER CYLINDER

(1) | Nipple | (6) | Return spring | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Oil seal | (7) | Piston | T1: | 7.8 (0.8, 5.8) |

(3) | Straight pin | (8) | Piston stop ring | T2: | 10 (1.0, 7.4) |

(4) | Master cylinder | (9) | Push rod ASSY | ||

(5) | Seat | (10) | Bleeder screw | ||

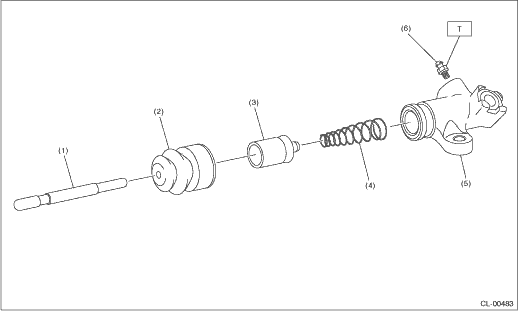

4. OPERATING CYLINDER

(1) | Push rod | (4) | Piston spring | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Boot | (5) | Operating cylinder | T: | 7.8 (0.8, 5.8) |

(3) | Piston | (6) | Bleeder screw | ||

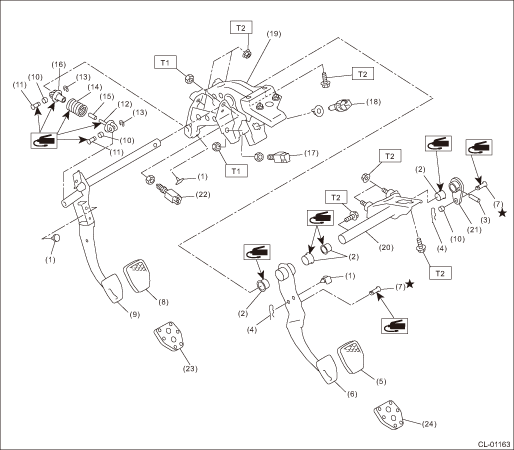

5. CLUTCH PEDAL

(1) | Stopper | (11) | Clutch clevis pin | (21) | Lever |

(2) | Pedal bushing | (12) | Assist rod A | (22) | Clutch start switch |

(3) | Spring pin | (13) | Clip | (23) | Clutch pedal pad (sport type) |

(4) | Snap pin | (14) | Assist spring | (24) | Brake pedal pad (sport type) |

(5) | Brake pedal pad (normal type) | (15) | Assist bushing | ||

(6) | Brake pedal | (16) | Assist rod B | Tightening torque: N·m (kgf-m, ft-lb) | |

(7) | Clevis pin | (17) | Clutch switch | T1: | 8 (0.8, 5.9) |

(8) | Clutch pedal pad (normal type) | (18) | Stop light switch | T2: | 18 (1.8, 13.3) |

(9) | Clutch pedal | (19) | Pedal bracket | ||

(10) | Bushing C | (20) | Clutch master cylinder bracket | ||

Specification

Specification

CLUTCH SYSTEM > General DescriptionSPECIFICATIONModel2.0 LTransmission type5MTClutch coverTypePush typeDiaphragm set loadN (kgf, lbf)5,688 (580, 1,279)Clutch discFacing materialWoven (non-asbestos) ...

Preparation tool

Preparation tool

CLUTCH SYSTEM > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS498497100CRANKSHAFT STOPPERUsed for stopping rotation of the flywheel.499747100CLUTCH DISC ...

Other materials:

Shifting speeds

Recommended shifting speeds

The best compromise between fuel economy

and vehicle performance during

normal driving is ensured by shifting up

at the speeds listed in the following table.

Maximum allowable speeds

The following table shows the maximum

speeds that are possible with each differe ...

Battery drainage prevention function

If a door or the rear gate is not completely

closed, the interior lights will remain

illuminated as a result. However, several

lights are automatically turned off by the

battery drainage prevention function to

prevent the battery from discharging. The

following interior lights are affected by ...

Dtc p0452 evap system (cpc) pressure sensor/switch circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0452 EVAP SYSTEM (CPC) PRESSURE SENSOR/SWITCH CIRCUIT LOWDTC detecting condition:Immediately at fault recognitionCAUTION:After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode ...