Subaru Crosstrek Service Manual: Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft Assembly

ASSEMBLY

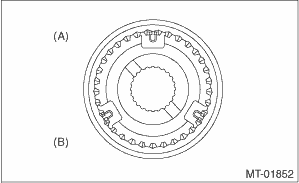

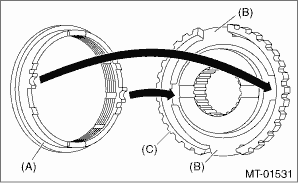

1. When the sleeve & hub assemblies have been disassembled, reassemble by aligning the alignment marks.

NOTE:

Position the open ends of the spring 120° apart.

(A) | 3rd-4th coupling sleeve & synchronizer hub ASSY |

(B) | 3rd gear side |

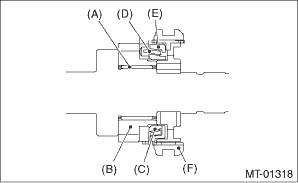

2. Install the 3rd drive gear, outer baulk ring, 3rd synchro cone, inner baulk ring, 3rd needle bearing, and sleeve & hub assembly.

NOTE:

Align the groove of the baulk ring with the 3rd-4th shifting insert.

(A) | 3rd needle bearing |

(B) | 3rd drive gear |

(C) | Inner baulk ring |

(D) | 3rd synchro cone |

(E) | Outer baulk ring |

(F) | Sleeve & hub ASSY |

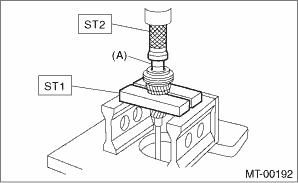

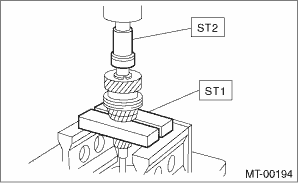

3. Install the 4th needle bearing race using ST1, ST2 and a press.

CAUTION:

Do not apply a load in excess of 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

| ST1 899714110 | REMOVER |

| ST2 499877000 | RACE 4-5 INSTALLER |

(A) | 4th needle bearing race |

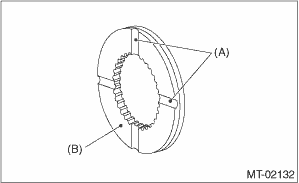

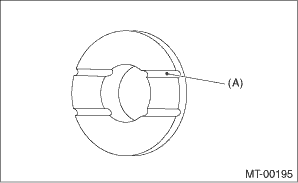

4. Install the 4th baulk ring, 4th needle bearing, 4th drive gear, and 4th gear thrust washer to the main shaft.

NOTE:

• Align the 4th baulk ring and hub & sleeve assembly with the key groove.

• Make sure the thrust washer is facing the correct direction.

(A) | Groove |

(B) | Face this surface to the 4th gear side. |

5. Press-fit the double ball bearing with ST1, ST2 and a press.

CAUTION:

Do not apply a load in excess of 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

NOTE:

• Install the snap ring side of the double ball bearing facing the 5th drive gear side.

• Use a new double ball bearing.

| ST1 899714110 | REMOVER |

| ST2 499877000 | RACE 4-5 INSTALLER |

6. Using the ST1 and ST2, install the 5th gear thrust washer and 5th needle bearing race onto the rear section of the main shaft.

CAUTION:

Do not apply a load in excess of 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).

NOTE:

Make sure the thrust washer is facing the correct direction.

| ST1 899714110 | REMOVER |

| ST2 499877000 | RACE 4-5 INSTALLER |

(A) | Face this surface to the 5th gear side. |

7. Install the rest of the parts to the rear section of the main shaft.

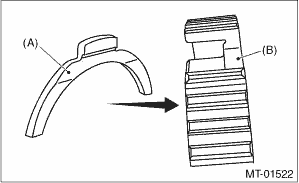

CAUTION:

• Install the baulk lever so that the concave side faces toward the 5th hub.

(A) | Baulk lever |

(B) | 5th hub |

• Align the protruded section of the 5th baulk ring between the baulk levers.

(A) | 5th baulk ring |

(B) | Baulk lever |

(C) | 5th hub |

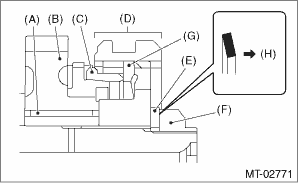

8. Tighten the lock nuts to the specified torque using ST1 and ST2.

NOTE:

• Use new lock nuts and lock washers.

• Make sure the lock washer is installed in the proper direction.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

| ST1 499987003 | SOCKET WRENCH (35) |

| ST2 498937000 | TRANSMISSION HOLDER |

(A) | 5th needle bearing |

(B) | 5th drive gear |

(C) | 5th baulk ring |

(D) | 5th hub & sleeve No. 2 |

(E) | Lock washer |

(F) | Lock nut |

(G) | Baulk lever |

(H) | Nut side |

9. Crimp lock nuts in two locations after tightening.

CAUTION:

When crimping the lock nut, be careful not to crack it.

Removal

Removal

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft AssemblyREMOVAL1. Remove the manual transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the ...

Disassembly

Disassembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft AssemblyDISASSEMBLY1. Put vinyl tape around main shaft spline to protect the oil seal from damage. Then pull out the oil seal and needle beari ...

Other materials:

Inspection

WIPER AND WASHER SYSTEMS > Relay and FuseINSPECTION1. CHECK FUSE1. Remove the fuse and inspect visually.2. If the fuse is blown out, replace the fuse.2. CHECK RELAY1. Check the resistance between relay terminals.Terminal No.Inspection conditionsStandardCircuit1 — 2Always1 M? or more1 — 2Apply ...

Inspection

HVAC SYSTEM (HEATER, VENTILATOR AND A/C) > Blower MotorINSPECTION1. Check the motor operation when battery voltage is applied between the terminals of motor.Terminal No.Inspection conditionsSpecificationConnection diagram2 (+) — 1 (−)Connect battery to the terminalsRotation2. If it does n ...

Dtc p0517 battery temperature sensor circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0517 BATTERY TEMPERATURE SENSOR CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionCAUTION:After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATI ...