Subaru Crosstrek Service Manual: Installation

MECHANICAL(H4DO) > V-belt

INSTALLATION

1. V-BELT

Install in the reverse order of removal.

CAUTION:

• When reusing the V-belt, wipe off dust and water with cloth.

• Do not use the V-belt if there is any oil, grease or coolant on the belt.

• Be careful not to rub the V-belt end surface with bare hands; exposed core may cause injury.

• Wipe off any dust, oil and water on the groove of each pulley with cloth.

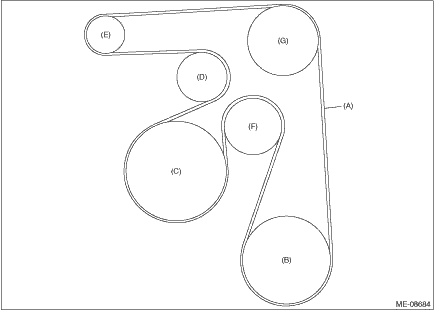

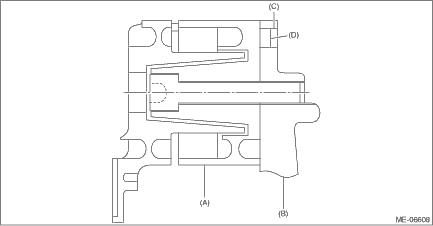

(A) | V-belt | (D) | V-belt tensioner ASSY | (G) | A/C compressor pulley |

(B) | Water pump pulley | (E) | Generator pulley | ||

(C) | Crank pulley | (F) | Idler pulley |

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

2. V-BELT TENSIONER ASSEMBLY AND IDLER PULLEY

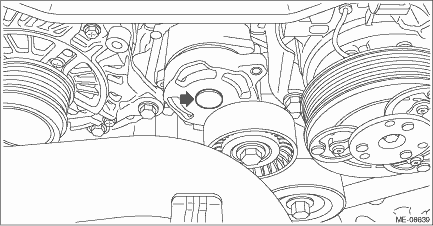

1. Install the idler pulley to the chain cover.

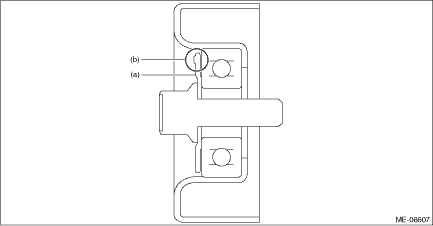

NOTE:

When installing the idler pulley, be careful of the idler pulley cover direction.

(a) | Idler pulley cover | (b) | Protrusion (3 places) |

Tightening torque:

36 N·m (3.7 kgf-m, 26.6 ft-lb)

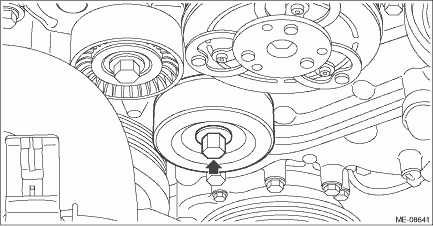

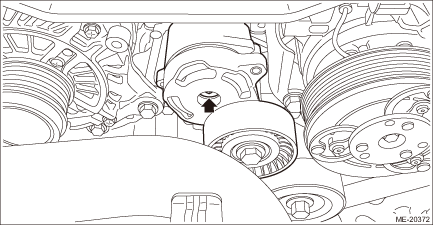

2. Install the V-belt tensioner assembly onto the generator bracket.

NOTE:

When installing the V-belt tensioner assembly, insert the protrusion of V-belt tensioner assembly into the hole for preventing rotation at the generator bracket.

(A) | V-belt tensioner ASSY | (C) | Hole to prevent rotation | (D) | Protrusion portion |

(B) | Generator bracket |

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

3. Install the cap to the V-belt tensioner assembly.

4. Install the V-belts.

Removal

Removal

MECHANICAL(H4DO) > V-beltREMOVALNOTE:When replacing a single part, perform the work with the engine assembly installed to body.1. V-BELT1. When working on the vehicleNOTE:When working on the vehicl ...

Compression Inspection

Compression Inspection

MECHANICAL(H4DO) > CompressionINSPECTIONCAUTION:After warming-up, engine becomes very hot. Be careful not to burn yourself during measurement.1. Turn the ignition switch to OFF.2. After warming-up ...

Other materials:

Caution

EXHAUST(H4DO) > General DescriptionCAUTION• Prior to starting work, pay special attention to the following:1. Always wear work clothes, a work cap, and protective shoes. Additionally, wear a helmet, protective goggles, etc. if necessary.2. Protect the vehicle using a seat cover, fender cove ...

Removal

GLASS/WINDOWS/MIRRORS > Front Door GlassREMOVAL1. Disconnect the ground cable from battery and wait for at least 60 seconds before starting work. NOTE">2. Remove the trim panel - front door. Door Trim > REMOVAL">3. Remove the sealing cover - front door. Front Sealing Cover & ...

Basic operation

Control switch

Up (select)

ENTER (push)

Down (select)

By operating "

" or "

" of the control

switch, the screens and selection items

can be switched. When the button is

pushed, the item can be selected and set. ...