Subaru Crosstrek Service Manual: Inspection

STARTING/CHARGING SYSTEMS(H4DO) > Starter

INSPECTION

NOTE:

• After the inspection, reinstall the disassembled or removed parts during the inspection in the reverse order of disassembly/removal procedure.

• Refer to component for tightening torque of each part. General Description > COMPONENT">

1. ARMATURE

1. Check the commutator for signs of seizure or stepped wear caused by roughness of the surface. If there is light wear, use sandpaper to repair.

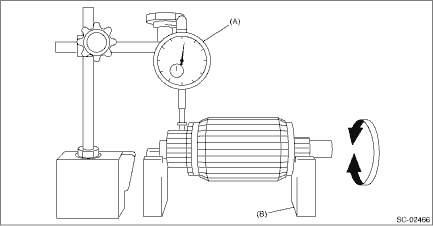

2. Check for runout on the commutator. If excessive, replace the armature.

Commutator runout:

Standard

0.05 mm (0.0020 in)

Limit

0.10 mm (0.0039 in)

(A) | Dial gauge | (B) | V-block |

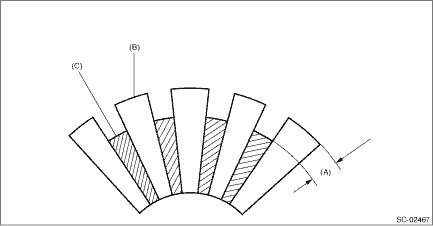

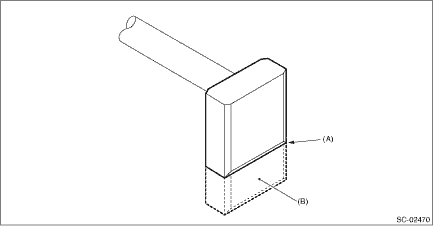

3. Check the depth of the segment mold. If it is not within the standard, replace the armature.

Depth of segment mold:

Standard

0.50 mm (0.020 in)

(A) | Depth of mold | (B) | Segment | (C) | Mold |

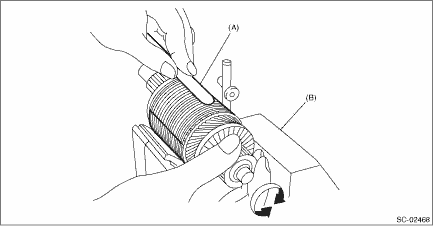

4. Place the armature on the growler tester to check for short circuits. While slowly turning the armature, support the steel sheet for the armature core. If the circuit of the armature is shorted, the steel sheet will vibrate, causing it to move towards the core. When the steel sheet has moved or vibrated, replace the armature.

(A) | Steel sheet | (B) | Growler tester |

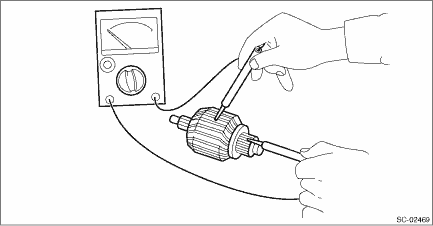

5. Use a circuit tester to touch the probe of one side to the commutator segment, and the other probe to the shaft. If there is continuity, replace the armature.

2. YOKE

Make sure that the pole is set at the predetermined position.

3. OVERRUNNING CLUTCH

Inspect the pinion, and if there is any wear or damage, replace the overrunning clutch. Also, check that the pinion rotates counterclockwise smoothly and does not rotate clockwise. If there is any fault, replace the overrunning clutch.

CAUTION:

To prevent spilling of grease, do not clean the overrunning clutch with oil.

4. BRUSH AND BRUSH HOLDER

1. Visually check the brush. If there is any abnormal wear or cracks, replace the brush.

2. Measure the length of the brush. If it exceeds service limits, replace the brush.

Brush length:

Standard

12.3 mm (0.484 in)

Limit

7.0 mm (0.276 in)

(A) | Service limit line | (B) | Brush |

3. Check that the brush moves smoothly in the brush holder.

4. Measure the brush spring force with a spring scale. Replace the brush holder if below the service limit.

Brush spring force:

Standard

15.9 — 19.5 N (1.62 — 1.99 kgf, 3.57 — 4.38 lbf) (when new)

Limit

2.5 N (0.25 kgf, 0.56 lbf)

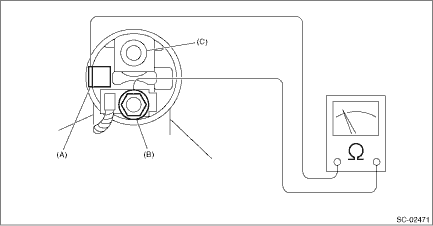

5. SWITCH ASSEMBLY

Using a circuit tester, check there is continuity between S terminal and M terminal, and between S terminal and ground. Also, check that there is no continuity between M terminal and B terminal.

(A) | Terminal S | (B) | Terminal M | (C) | Terminal B |

Terminals | Standard |

Terminal S — terminal M | 1 ? or less |

Terminal S — Ground | 1 ? or less |

Terminal M — terminal B | 1 M? or more |

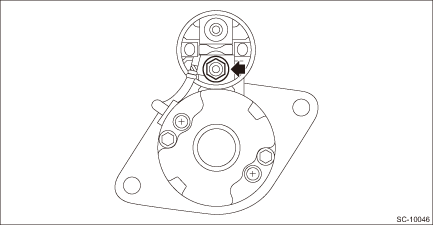

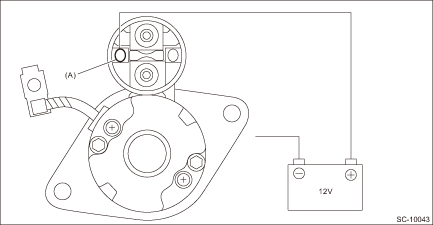

6. SWITCH ASSEMBLY OPERATION

CAUTION:

Perform the inspection in a short period of time. (Within 3 to 5 seconds)

1. Loosen the nut which holds the cable to the M terminal.

NOTE:

This procedure is required to facilitate the cable removal from the M terminal.

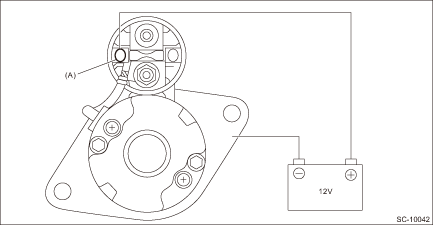

2. Connect the battery positive terminal to the switch assembly S terminal, and connect the battery negative terminal to the starter body. Then, if the pinion protrudes, it is normal.

NOTE:

The starter motor may rotate while the pinion protrudes. This occurs due to current that flows to the motor via pull-in coil. This is not a problem.

(A) | Terminal S |

3. Disconnect the cable from the M terminal. Check that the pinion is being protruded at this time.

CAUTION:

Hold the disconnected cable so that it does not contact the terminal or wiring.

4. Disconnect the battery negative terminal from the starter body. Then, if the pinion returns to its original position, it is normal.

(A) | Terminal S |

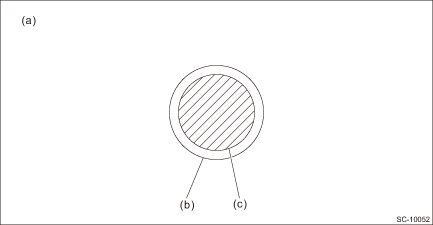

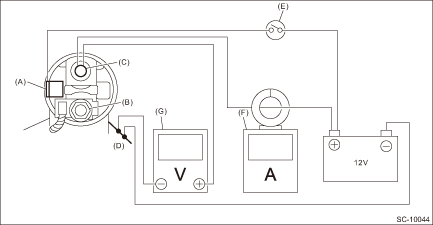

7. NO-LOAD TEST

CAUTION:

• Use a thick cable due to large current flowing through the cable.

• It is recommended that the cross-section area of continuity part (shaded part) should be 20 mm2 (0.00310 sq in) or more for terminal B and ground, and 1.25 mm2 (0.00194 sq in) or more for terminal S.

(a) | Cable cross-section | (b) | Cable shield part | (c) | Cable continuity part |

• It is possible to use a booster cable instead of wiring.

• Be careful not to burn yourself and cause a fire due to heat.

• Perform the no-load test in a short period of time. (Within 3 to 5 seconds)

NOTE:

For no-load test, use the circuit shown in figure.

(A) | Terminal S | (B) | Terminal M | (C) | Terminal B |

(D) | Magnet switch | (E) | Switch | (F) | Circuit tester with clamp-type ammeter |

(G) | Circuit tester |

1. Using a vise, secure the starter.

CAUTION:

Be careful not to deform or damage the starter.

2. Turn the switch ON, and check that the pinion protrudes rapidly into the specified position and rotates powerfully without noise.

3. Check the current and voltage after its rotation speed stabilizes.

Current/Voltage

CVT model

90 A or less (approx. 11 V)

MT model

95 A or less (approx. 11 V)

8. OTHER INSPECTIONS

Check that the starter does not have deformation, cracks and any other damage.

Disassembly

Disassembly

STARTING/CHARGING SYSTEMS(H4DO) > StarterDISASSEMBLYCAUTION:The starter should be placed through a no-load test whenever it has been overhauled.1. Disconnect the cable from the magnet switch assemb ...

Installation

Installation

STARTING/CHARGING SYSTEMS(H4DO) > StarterINSTALLATIONInstall in the reverse order of removal.NOTE:• For CVT model, a nut is used at (a).• Tighten the starter and cable stay (b) together ...

Other materials:

Removal

POWER ASSISTED SYSTEM (POWER STEERING) > Steering WheelREMOVALCAUTION:Before handling the airbag system components, always refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">1. Set the tire to the straight ...

Specification

DIFFERENTIALS > General DescriptionSPECIFICATION1. REAR DIFFERENTIALWhen replacing a rear differential assembly, select the correct one according to the following table.NOTE:• Using a different rear differential assembly will cause the drive train and tires to drag or emit abnormal noise.&b ...

Service mode (models without "keyless access with push-button start system")

In service mode, the remote engine start

function is temporarily disabled to prevent

the system from unexpectedly starting the

engine while being serviced.

To engage or disengage service mode:

1. Enter the vehicle and close all vehicle

doors and the rear gate.

2. Verify that the select le ...