Subaru Crosstrek Service Manual: Inspection

STARTING/CHARGING SYSTEMS(H4DO) > Generator

INSPECTION

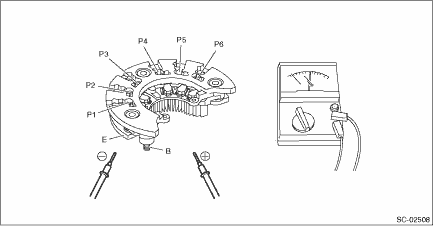

1. DIODE

CAUTION:

There is the possibility of damaging the diodes if a mega-tester (used to measure high voltages) or a similar measuring instrument is used. Never use a mega tester or equivalent for this test.

1. Check for continuity between the diode lead and terminal E or B. If continuity is not as shown in the table, replace the rectifier.

• At analog type tester

Tester lead | Continuity | |

−lead | +lead | |

E | P1, P2, P3, P4, P5, P6 | Yes |

B | No | |

P1, P2, P3, P4, P5, P6 | E | No |

B | Yes | |

• At digital type tester

Tester lead | Continuity | |

−lead | +lead | |

E | P1, P2, P3, P4, P5, P6 | No |

B | Yes | |

P1, P2, P3, P4, P5, P6 | E | Yes |

B | No | |

2. ROTOR

1. Slip ring surface

Inspect the slip rings for contamination or any roughness on the sliding surface. Repair the slip ring surface using a lathe or sand paper.

2. Slip ring outer diameter

Measure the slip ring outer diameter. Replace the rotor if the slip ring is worn.

Slip ring outer diameter:

Standard

22.7 mm (0.894 in)

Limit

22.1 mm (0.870 in)

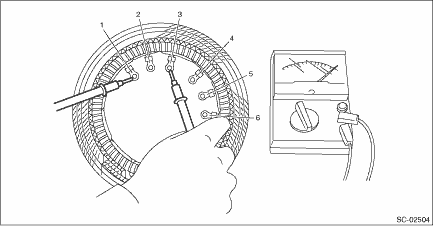

3. Continuity test

Using a circuit tester, check the resistance between slip rings. If the resistance is not within the standard, replace the rotor.

Standard:

Approx. 2.0 — 2.4 ?

4. Insulation test

Check the continuity between slip ring and rotor core or shaft. If there is continuity, replace the rotor because the rotor coil is grounded.

5. Bearing

Check the bearings. If there is any noise, or the rotor does not rotate smoothly, replace the bearings.

3. STATOR COIL

1. Continuity test

Inspect the continuity between the stator coil terminals. If continuity is not as shown in the table, replace the stator coil.

(A) | Terminals |

2. Insulation test

Inspect the continuity between the stator coil stator core and lead wire terminals. If there is continuity, replace the stator coil because the stator coil is grounded.

4. BRUSH

1. Measure the length of each brush. Replace the brush if wear exceeds service limits. There is a service limit mark (A) on each brush.

Brush length:

Standard (1)

22.5 mm (0.886 in)

Limit (2)

5.0 mm (0.197 in)

2. Check that there is appropriate pressure on the brush spring. Using a spring pressure indicator, push the brush into the brush holder until its tip protrudes 2 mm (0.0787 in). Then measure the pressure of brush spring. If the pressure is 1.7 N (173 gf, 6.11 ozf) or less, replace the brush spring. 4.1 — 5.3 N (418 — 540 gf, 14.75 — 19.06 ozf) pressure is required on the new spring.

5. BALL BEARING

Check the ball bearings. Replace the ball bearings if there is resistance in the rotation, or if there is any abnormal noise.

Disassembly

Disassembly

STARTING/CHARGING SYSTEMS(H4DO) > GeneratorDISASSEMBLY1. Remove the cap from the generator.2. Remove four bolts.3. Use a drier to heat the rear cover (A) portion to 50 — 60°C (122 — ...

Installation

Installation

STARTING/CHARGING SYSTEMS(H4DO) > GeneratorINSTALLATION1. Temporarily install the generator bracket to the engine and tighten the bolts in the numerical order.Tightening torque:36 N·m (3.7 k ...

Other materials:

Caution

POWER ASSISTED SYSTEM (POWER STEERING) > General DescriptionCAUTION• Wear appropriate work clothing, including a helmet, protective goggles and protective shoes when performing any work.• Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary re ...

Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transfer ClutchADJUSTMENT1. Install the transfer clutch assembly to the extension case with the transfer driven gear shims and thrust bearings removed.2. Install the thrust bearing to the transfer driven gear.NOTE:Make sure to install in the right direc ...

Basic diagnostic procedure Procedure

CRUISE CONTROL SYSTEM (DIAGNOSTICS) > Basic Diagnostic ProcedurePROCEDURECAUTION:• Before performing all diagnostics or cruise control diagnostics, always start the engine and make sure that the initial illumination of the ABS/VDC warning light has been ended. (If you start the diagnostics ...