Subaru Crosstrek Service Manual: Inspection

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft Assembly

INSPECTION

Disassembled parts should be washed with cleaning solvent first, then inspected carefully.

1. Bearing

Replace the bearings in the following cases.

• When the bearing balls, outer races and inner races are broken or rusty.

• When the bearing is worn.

• When the bearings fail to turn smoothly or emit noise in rotation after transmission gear oil has been applied.

• When bearing has other defects.

2. Bushing (each gear)

Replace the bushing in following cases.

• When the sliding surface is damaged or abnormally worn.

• When the inner wall is abnormally worn.

3. Gear

Replace gears in the following cases.

• Replace the gear with new part if its tooth surfaces are broken, damaged or excessively worn.

• Correct or replace if the cone that contacts the baulk ring is rough or damaged.

• Correct or replace if the inner surface or end face is damaged.

4. Baulk ring, synchro cone

Replace the baulk ring and synchro cone in the following cases.

• When the inner surface and end face are damaged.

• When the baulk ring inner surface is abnormally or partially worn down.

• When the contact surface of the baulk ring insert section is cracked or abnormally worn.

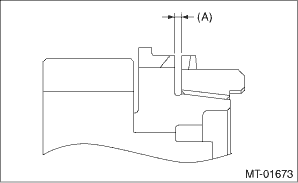

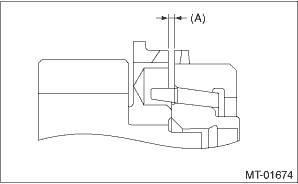

• If the gap between the end faces of the baulk ring and the gear splined part is excessively small, check the clearance (A) while pressing the ring against the cone.

Clearance (A):

0.5 mm (0.020 in) or more

Single cone

Double cone

• Apply transmission gear oil to the cone of the gear and while press-fitting the baulk ring, check there is no rotation in the circumferential direction.

5. Shifting insert

Replace the shifting insert if deformed, excessively worn or defective in any way.

6. Coupling sleeve and synchronizer hub

• Check the slipping condition of the coupling sleeve.

• Check the splines on the coupling sleeve and synchronizer hub for wear.

7. Oil seal

Replace the oil seal if the lip is deformed, hardened, worn or defective in any way.

8. Gearshift mechanism

Repair or replace the gearshift mechanism if excessively worn, bent or defective in any way.

Disassembly

Disassembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft AssemblyDISASSEMBLY1. Put vinyl tape around main shaft spline to protect the oil seal from damage. Then pull out the oil seal and needle beari ...

Installation

Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft AssemblyINSTALLATION1. Attach the needle bearing and oil seal to the front of the main shaft assembly.NOTE:• Wrap the clutch splined sec ...

Other materials:

Installation

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF) > Glass LidINSTALLATION1. GLASS LID1. Using a new TORX® bolt, install the lid assembly - sunroof.Tightening torque:4.5 N·m (0.46 kgf-m, 3.3 ft-lb)2. Perform the open/close operation checks for the glass lid.3. Check the height of the lid assembly - ...

Dtc p0024 "b" camshaft position - timing over-advanced or system performance bank 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0024 "B" CAMSHAFT POSITION - TIMING OVER-ADVANCED OR SYSTEM PERFORMANCE BANK 2DTC detecting condition:Detected when two consecutive driving cycles with fault occur.Trouble symptom:• Engine sta ...

Dtc p0700 transmission control system (mil request)

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0700 TRANSMISSION CONTROL SYSTEM (MIL REQUEST)NOTE:For the diagnostic procedure, refer to CVT section. Basic Diagnostic Procedure">1. OUTLINE OF DIAGNOSISJudge as NG when there is CAN communication w ...