Subaru Crosstrek Service Manual: Inspection

CONTROL SYSTEMS > MT Gear Shift Lever

INSPECTION

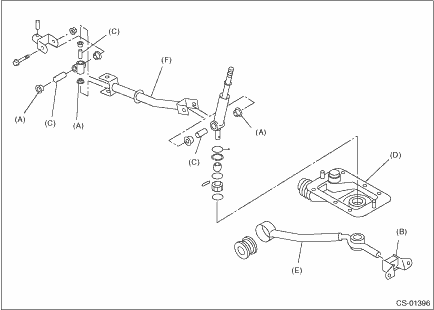

1. Check the parts (bushing, cushion rubber, spacer, boot, stay and rod, etc.) for deformation, damage and wear. If necessary, correct or replace faulty parts. Compare the removed parts with new parts to judge if there are damages or not.

(A) | Bushing |

(B) | Cushion rubber |

(C) | Spacer |

(D) | Boot |

(E) | Stay |

(F) | Rod |

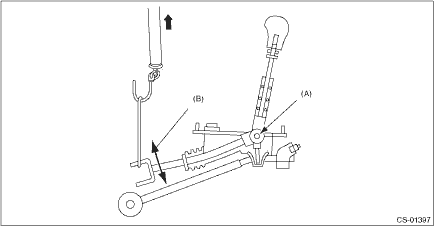

2. Check the swing torque of rod linked with the gear shift lever. If the torque exceeds the specifications, replace the bushing or retighten nuts.

Swing torque:

3.7 N (0.38 kgf, 0.83 lbf) or less

(A) | Pivot |

(B) | Swing torque |

Disassembly

Disassembly

CONTROL SYSTEMS > MT Gear Shift LeverDISASSEMBLY1. Remove the lock wires.(A)Lock wire2. Remove the rod from gear shift lever.(A)Rod(B)Lever(C)Stay3. Separate the rod and inner boot.4. Remove the sn ...

Installation

Installation

CONTROL SYSTEMS > MT Gear Shift LeverINSTALLATION1. Insert the gear shift lever from the room side.NOTE:Insert the rod and the stay, and then temporarily set them onto the transmission mount.2. Lif ...

Other materials:

Dtc c2322 transmitter 2 function code abnormal

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C2322 TRANSMITTER 2 FUNCTION CODE ABNORMALNOTE:Refer to DTC C2324 for diagnostic procedure. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC C2324 TRANSMITTER 4 FUNCTION COD ...

Dtc u0155 lost communication with instrument panel cluster (ipc) control module

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0155 LOST COMMUNICATION WITH INSTRUMENT PANEL CLUSTER (IPC) CONTROL MODULENOTE:For the diagnostic procedure, refer to LAN section. Basic Diagnostic Procedure">1. OUTLINE OF DIAGNOSISDetect malfunctio ...

Operation

VEHICLE DYNAMICS CONTROL (VDC) > VDC Sequence ControlOPERATION1. While the VDC sequence control is performed, the operation of the hydraulic unit can be checked using the brake tester or pressure gauge after the hydraulic unit solenoid valve is operated.2. VDC sequence control can be started by S ...