Subaru Crosstrek Service Manual: Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transfer Clutch

INSPECTION

• Inspect the drive plate facing for wear and damage.

• Driven plate for discoloration (burned color)

• Make sure the snap ring is not worn and the return spring has no permanent distortion, damage, or deformation.

• Check the lip seal for damage.

• Inspect the extension end play, and adjust it to within the standard value. Transfer Clutch > ADJUSTMENT">

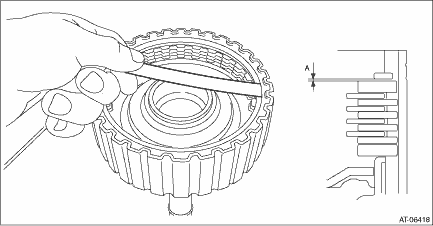

1. Before measuring clearance “A” between snap ring and driven plate, place same thickness shims on both sides to prevent the plate from tilting.

2. When clearance “A” exceeds the limit for use, replace the drive plate and driven plate as a set, and select the pressure plate within the initial specified value.

Initial standard:

0.7 — 1.1 mm (0.028 — 0.043 in)

Limit thickness:

1.3 mm (0.051 in)

3. Check for tight corner braking phenomenon when the vehicle is moved forward with the steering fully turned. If tight corner braking occurs, perform the following procedures.

(1) With the steering wheel held at fully turned position, drive the vehicle in “D” range and with vehicle speed at approx. 5 km/h (3 MPH) in both clockwise and counterclockwise directions for approx. ten times each, while repeating acceleration and braking intermittently.

(2) If the tight corner braking phenomenon still persists, drive the vehicle again in a circle for several laps.

Disassembly

Disassembly

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transfer ClutchDISASSEMBLY1. Remove the snap ring, and then remove the pressure plate, drive plate and driven plate.(A)Snap ring2. Compress the return sp ...

Installation

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transfer ClutchINSTALLATION1. Install the thrust bearing.NOTE:Make sure to install in the right direction.2. Install the transfer clutch assembly.3. Sele ...

Other materials:

Disassembly

MECHANICAL(H4DO) > Chain CoverDISASSEMBLY1. Remove the oil filler cap.2. Remove the engine oil filter and the oil pump union. Engine Oil Filter > REMOVAL">3. Remove the oil pressure switch. Oil Pressure Switch > REMOVAL">4. Remove the engine oil temperature sensor. Engine ...

Forced drive

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF) > Glass LidFORCED DRIVEIf the lid assembly - sunroof does not operate or the motor assembly is not supplied with power, move the lid assembly - sunroof using the hexagon wrench.Preparation tool:Hexagon wrench: width across flat 4 mm (0.16 in)CAUTION:After a ...

Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel InjectorINSPECTION1. Check that the fuel injector has no deformation, cracks or other damages.2. Measure the resistance between fuel injector terminals.Terminal No.Standard1 and 2Approx. 12.0 ? (when 20°C (68°F)) ...