Subaru Crosstrek Service Manual: Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Inhibitor Switch

INSPECTION

When the driving condition or starter motor operation is improper, first check the shift linkage for improper operation. If the shift linkage is functioning properly, check the inhibitor switch.

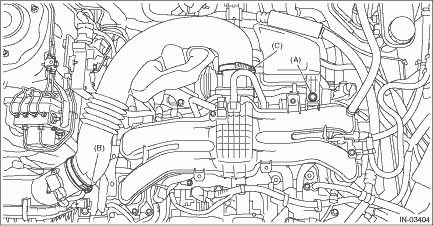

1. Remove the clip (A) from the air intake boot.

2. Loosen the clamp (B) connecting the air intake boot and air cleaner case (rear).

3. Loosen the clamp (C) which connects the air intake boot and throttle body.

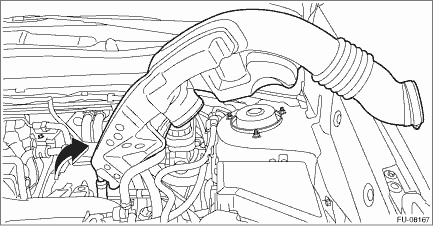

4. Remove the air intake boot from the throttle body, and move it to the left side wheel apron.

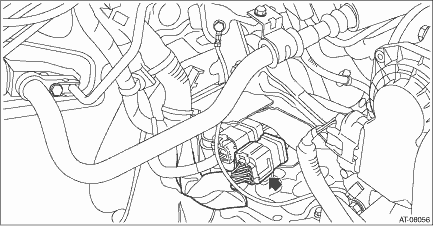

5. Disconnect the inhibitor harness connector.

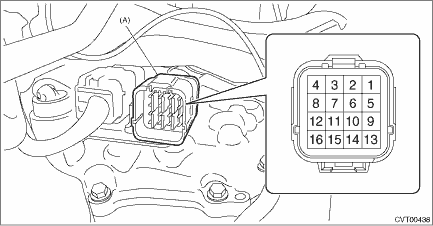

6. Check for continuity in inhibitor switch circuit by shifting the select lever in “P”, “R”, “N” and “D” respectively.

NOTE:

• Check that there is no continuity in the starter circuit when the select lever is in the “R” and “D” ranges.

• When inhibitor switch is normal, check there is no poor contact in vehicle side connector and no open circuit in harness.

Signal sent to TCM | Range | Terminal No. |

P | 1 — 7 | |

R | 2 — 7 | |

N | 3 — 7 | |

D | 4 — 7 | |

Starter circuit | P/N | 15 — 16 |

Back-up light circuit | R | 13 — 14 |

(A) | Inhibitor harness connector |

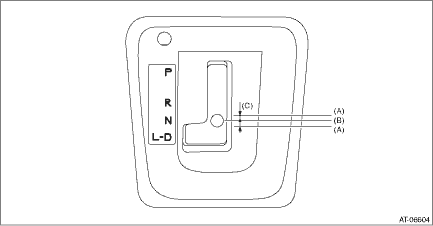

7. Check that there is continuity at equal points when the select lever is moved 1.5° in both directions from the “N” range.

If there is continuity in only one direction or in other points, adjust the inhibitor switch. Inhibitor Switch > ADJUSTMENT">

(A) | Continuity does not exist. |

(B) | Continuity exists. |

(C) | 1.5° |

8. Repeat the above inspection in other gear ranges. If there is fault, adjust the inhibitor switch and select cable. Inhibitor Switch > ADJUSTMENT"> Select Cable > ADJUSTMENT">

Select Cable > ADJUSTMENT">

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Inhibitor SwitchREMOVAL1. Shift the select lever to “N” range.2. Disconnect the ground cable from battery. NOTE">NOTE:For model with ...

Installation

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Inhibitor SwitchINSTALLATION1. Install the inhibitor switch to the transmission case temporarily.2. Connect the inhibitor harness connector to the inhibi ...

Other materials:

Installation

WIPER AND WASHER SYSTEMS > Rear Wiper MotorINSTALLATION1. Install each part in the reverse order of removal.2. Check that the mark on the cap - pivot wiper faces up, as shown in the figure.Tightening torque:Refer to “COMPONENT” of “General Description”. General Descriptio ...

Operating range for push-button start system

Antenna

Operating range

NOTE

If the access key is not detected

within the operating range of the antennas

inside the vehicle, the pushbutton

ignition switch and the engine

start cannot be operated.

Even when the access key is outside

the vehicle, if it is placed too close to

the ...

Selecting an audio source

1. Press the AUDIO/TUNE knob.

2. Select the desired source.

Example: Source select screen

NOTE

If the audio control screen appears,

select the "Source" key on the audio

screen or press the AUDIO/TUNE knob

again.

When you push the AUDIO/TUNE

knob while any screen other than t ...