Subaru Crosstrek Service Manual: Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Inhibitor Switch

INSTALLATION

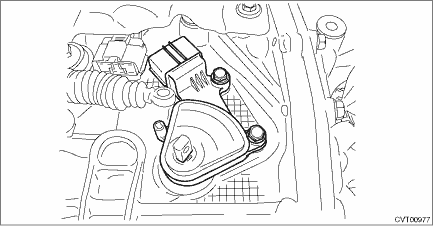

1. Install the inhibitor switch to the transmission case temporarily.

2. Connect the inhibitor harness connector to the inhibitor switch.

3. Install the shifter arm and fix with the spring pin.

NOTE:

Use new spring pin.

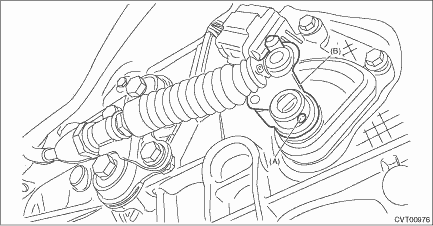

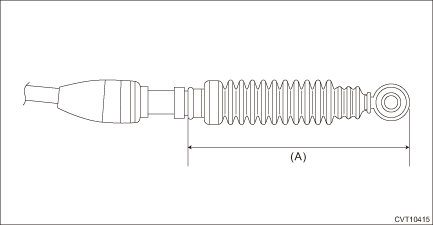

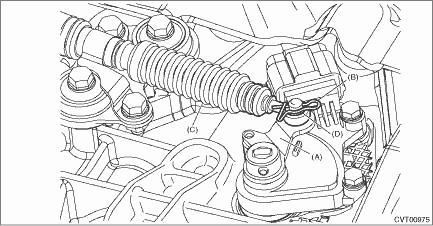

(A) | Spring pin |

(B) | Shifter arm |

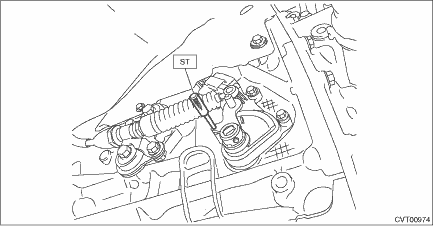

4. Shift the shifter arm to “N” range.

5. Install the ST vertically in the cutout of shifter arm and the hole of switch body.

| ST 499267300 | STOPPER PIN |

6. Tighten the two bolts holding the inhibitor switch.

Tightening torque:

5 N·m (0.5 kgf-m, 3.7 ft-lb)

7. Install the select cable to the shifter arm.

8. Install the washer and snap pin to the shifter arm.

CAUTION:

Do not apply extra overload while holding the part (A).

(A) | Shifter arm |

(B) | Snap pin |

(C) | Select cable |

(D) | Washer |

9. Install the center exhaust pipe. Center Exhaust Pipe > INSTALLATION">

10. Lower the vehicle.

11. Connect the battery ground terminal.

12. Check the inhibitor switch. Inhibitor Switch > INSPECTION">

Inspection

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Inhibitor SwitchINSPECTIONWhen the driving condition or starter motor operation is improper, first check the shift linkage for improper operation. If the ...

Other materials:

Dtc p0517 battery temperature sensor circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0517 BATTERY TEMPERATURE SENSOR CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionCAUTION:After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATI ...

Removal

COOLING(H4DO) > Radiator Main Fan and Fan MotorREMOVAL1. Disconnect the ground cable from battery. NOTE">2. Remove the reservoir tank. Reservoir Tank > REMOVAL">3. Disconnect the connector from the main fan motor assembly.4. Remove the bolts which hold the radiator main fan s ...

Note

SECURITY AND LOCKS > Body Integrated UnitNOTE1. REPLACE BODY INTEGRATED UNIT1. Check and record the current setting. Registration Body Integrated Unit > OPERATION">2. Prepare all immobilizer keys already registered. (Models without the keyless access with push button start)3. Replace ...