Subaru Crosstrek Service Manual: Dtc p0198 engine oil temperature sensor "a" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0198 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT HIGH

DTC detecting condition:

Immediately at fault recognition

Trouble symptom:

• Hard to start

• Improper idling

• Poor driving performance

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

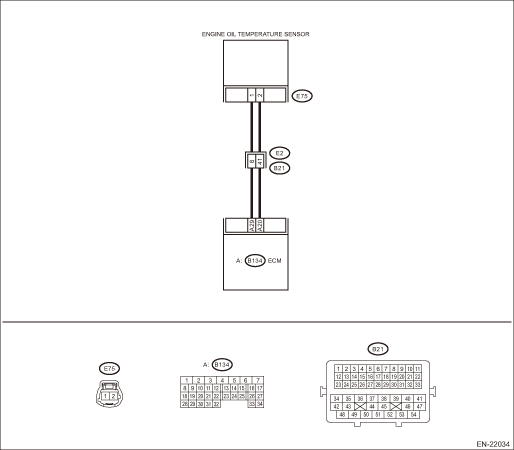

Wiring diagram:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK CURRENT DATA.

1) Start the engine.

2) Read the value of «Oil Temperature» using Subaru Select Monitor.

NOTE:

For detailed operation procedures, refer to “Current Data Display For Engine”. Subaru Select Monitor">

Is the value of «Oil Temperature» −40°C (−40°F) or less?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0198 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 2.

Even if DTC is detected, the circuit has returned to a normal condition at this time. Reproduce the failure, and then perform the diagnosis again.

NOTE:

In this case, temporary poor contact of connector, temporary open or short circuit of harness may be the cause.

2.CHECK FOR POOR CONTACT.

Check for poor contact between the ECM and engine oil temperature sensor connectors.

Is there poor contact of the ECM or engine oil temperature sensor connectors?

Repair the poor contact of ECM or engine oil temperature sensor connector.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0198 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 3.

3.CHECK HARNESS BETWEEN ECM AND ENGINE OIL TEMPERATURE SENSOR CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connectors from the engine oil temperature sensor.

4) Measure the resistance of the harness between the ECM connector and engine oil temperature sensor connector.

Connector & terminal

(B134) No. 29 — (E75) No. 1:

(B134) No. 20 — (E75) No. 2:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0198 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT HIGH">Go to Step 4.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and engine oil temperature sensor connector

• Poor contact of coupling connector

4.CHECK HARNESS BETWEEN ECM AND ENGINE OIL TEMPERATURE SENSOR CONNECTOR.

1) Connect all connectors.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM connector and chassis ground.

Connector & terminal

(B134) No. 20 (+) — Chassis ground (−):

Is the voltage 5 V or more?

Repair the short circuit to power in harness between ECM connector and engine oil temperature sensor connector.

Replace the engine oil temperature sensor. Engine Oil Temperature Sensor">

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of the oil temperature sensor.

Judge as NG when outside of the judgment value.

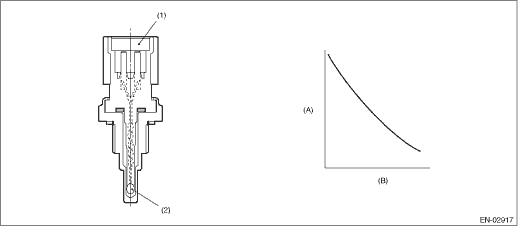

2. COMPONENT DESCRIPTION

(A) | Resistance value (k?) | (B) | Temperature °C (°F) | ||

(1) | Connector | (2) | Thermistor element |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

None |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Output voltage | ≥ 4.698 V |

Time Needed for Diagnosis: 500 ms

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p0197 engine oil temperature sensor "a" circuit low

Dtc p0197 engine oil temperature sensor "a" circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0197 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT LOWDTC detecting condition:Immediately at fault rec ...

Dtc p0201 cylinder 1 injector "a" circuit

Dtc p0201 cylinder 1 injector "a" circuit

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0201 CYLINDER 1 INJECTOR "A" CIRCUITDTC DETECTING CONDITION:Immediately at fault recognitionTROUBL ...

Other materials:

List of diagnostic trouble code (dtc) List

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > List of Diagnostic Trouble Code (DTC)LISTDTCItemContent of diagnosisNoteNoneWithout DTCNormal Subaru Select Monitor > INSPECTION">“Assist limitation” is displayed in the current data «EPS operating condition».Assist l ...

Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Drive Pinion Shaft AssemblyADJUSTMENT1. Remove the liquid gasket from the mating surface completely.2. Using the ST, install the drive pinion retainer to converter case.ST 18270KA020SOCKET (E20)NOTE:Do not confuse the three different-length bolts whe ...

Command list

Recognizable voice commands and their

actions are shown below.

NOTE

Some voice commands may not be

available depending on the market,

vehicle specifications or the device

connection status.

Frequently used commands are

listed in the following tables.

For devices that are not instal ...