Subaru Crosstrek Service Manual: Dtc p0030 a/f / o2 heater control circuit bank 1 sensor 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0030 A/F / O2 HEATER CONTROL CIRCUIT BANK 1 SENSOR 1

DTC detecting condition:

Detected when two consecutive driving cycles with fault occur.

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

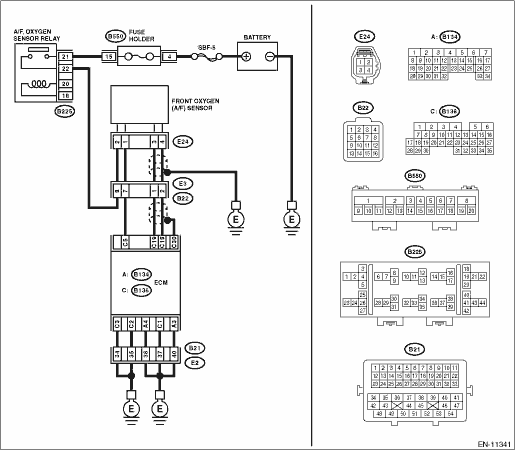

Wiring diagram:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK HARNESS BETWEEN ECM AND FRONT OXYGEN (A/F) SENSOR CONNECTOR.

1) Start and warm up the engine.

2) Turn the ignition switch to OFF.

3) Disconnect the connector from ECM.

4) Disconnect the connectors from front oxygen (A/F) sensor.

5) Measure the resistance of harness between ECM connector and front oxygen (A/F) sensor connector.

Connector & terminal

(B136) No. 5 — (E24) No. 1:

(B136) No. 19 — (E24) No. 3:

(B136) No. 18 — (E24) No. 4:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0030 A/F / O2 HEATER CONTROL CIRCUIT BANK 1 SENSOR 1">Go to Step 2.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and front oxygen (A/F) sensor connector

• Poor contact of coupling connector

2.CHECK FRONT OXYGEN (A/F) SENSOR.

Measure the resistance between front oxygen (A/F) sensor terminals.

Terminals

No. 1 — No. 2:

Is the resistance 2 — 3 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0030 A/F / O2 HEATER CONTROL CIRCUIT BANK 1 SENSOR 1">Go to Step 3.

Replace the front oxygen (A/F) sensor. Front Oxygen (A/F) Sensor">

3.CHECK FOR POOR CONTACT.

Check for poor contact of ECM and front oxygen (A/F) sensor connector.

Is there poor contact of ECM or front oxygen (A/F) sensor connector?

Repair the poor contact of ECM or front oxygen (A/F) sensor connector.

Replace the front oxygen (A/F) sensor. Front Oxygen (A/F) Sensor">

1. OUTLINE OF DIAGNOSIS

Detect functional errors of the front oxygen (A/F) sensor heater.

Judge as NG when it is determined that the front oxygen (A/F) sensor impedance is large when looking at engine status such as deceleration fuel cut.

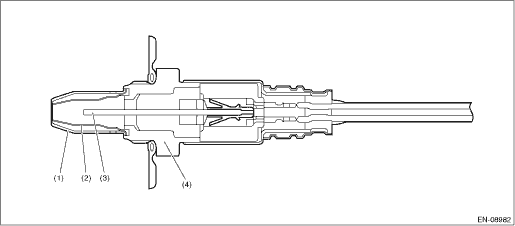

2. COMPONENT DESCRIPTION

(1) | Element cover (outer) | (3) | Sensor element | (4) | Sensor housing |

(2) | Element cover (inner) |

3. EXECUTION CONDITION

Secondary parameters | Execution condition |

Battery voltage | ≥ 10.9 V |

A/F sensor heater control duty | > 17 % |

Elapsed time after fuel cut | ≥ 20000 ms |

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously after 42000 ms seconds or more have passed since the engine started.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Front oxygen (A/F) sensor impedance | > 82 ? |

Time Needed for Diagnosis: 10000 ms

Malfunction Indicator Light Illumination: Illuminates when malfunction occurs in 2 continuous driving cycles.

Dtc p0024 "b" camshaft position - timing over-advanced or system performance bank 2

Dtc p0024 "b" camshaft position - timing over-advanced or system performance bank 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0024 "B" CAMSHAFT POSITION - TIMING OVER-ADVANCED OR SYSTEM PERFORMANCE BANK 2DTC detecting condit ...

Dtc p0031 a/f / o2 heater control circuit low bank 1 sensor 1

Dtc p0031 a/f / o2 heater control circuit low bank 1 sensor 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0031 A/F / O2 HEATER CONTROL CIRCUIT LOW BANK 1 SENSOR 1DTC DETECTING CONDITION:Immediately at fault recogni ...

Other materials:

Dtc u0122 lost communication with vehicle dynamics control module

AUTO HEADLIGHT BEAM LEVELER SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0122 LOST COMMUNICATION WITH VEHICLE DYNAMICS CONTROL MODULEDetected when CAN data (vehicle speed signal) is not received from VDC.NOTE:Perform the diagnosis for LAN system. Basic Diagn ...

Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Reduction Driven GearADJUSTMENT1. Measure the height “A” from the ST upper face to the ball bearing catch surface.ST 499575600GAUGE2. Measure the height “B” from the ST to the mating surface of the transmission case.ST 4995 ...

Dtc p0976 shift solenoid "b" control circuit low

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0976 SHIFT SOLENOID "B" CONTROL CIRCUIT LOWDTC detecting condition:Immediately at fault recognitionTrouble symptom:Gear is not changed. (No down-shift)CAUTION:Use the check boa ...