Subaru Crosstrek Service Manual: Disassembly

CONTROL SYSTEMS > Select Lever

DISASSEMBLY

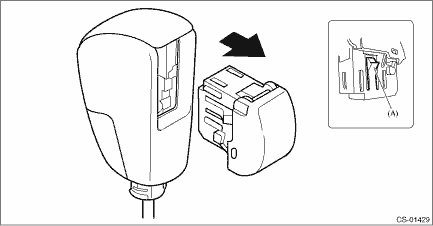

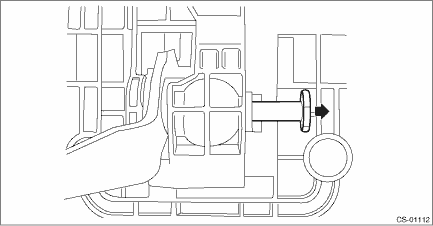

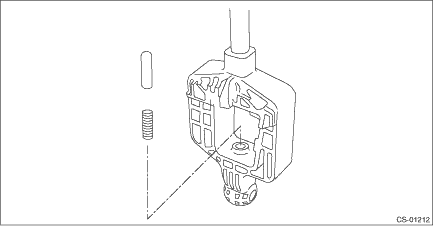

1. GRIP ASSY

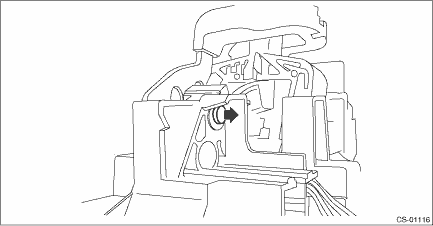

1. Remove the button assembly_AT.

(A) | Claw |

2. Remove the rod COMPL.

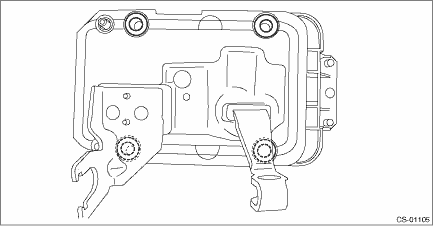

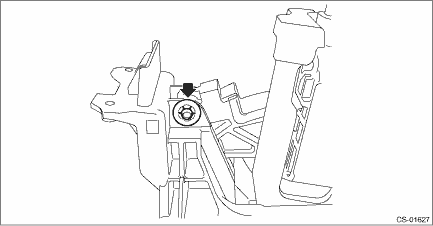

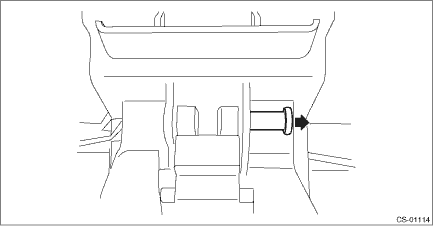

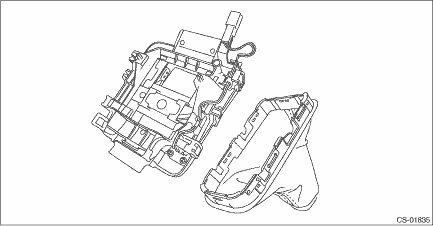

2. AT SELECT LEVER ASSEMBLY

1. Remove the spacer plate.

2. Remove the gasket.

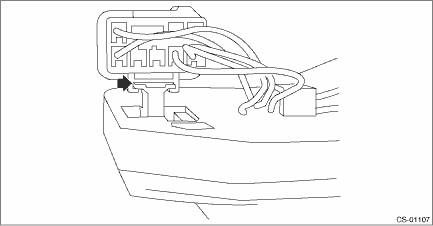

3. Insert a flat tip screwdriver with a thin tip under the connector and disconnect the harness connector from the plate COMPL.

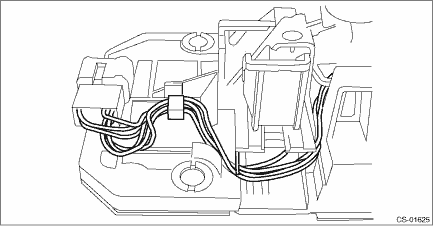

4. Remove the harness from the plate COMPL.

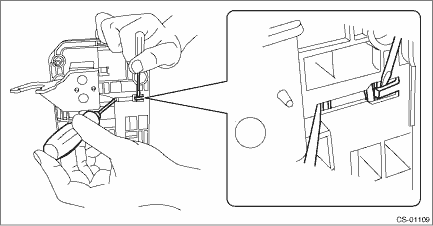

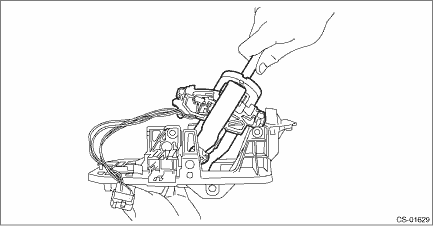

5. Raise the claw with a flat tip screwdriver with a thin tip and remove the solenoid unit.

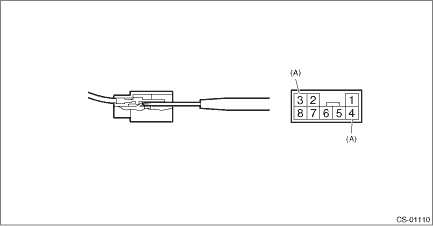

6. Remove the terminal of the solenoid unit using a flat tip precision screwdriver with a tip width of 1.3 mm (0.05 in) or less, KTC connector terminal tool ECC-1T or equivalent.

(A) | Solenoid unit terminals |

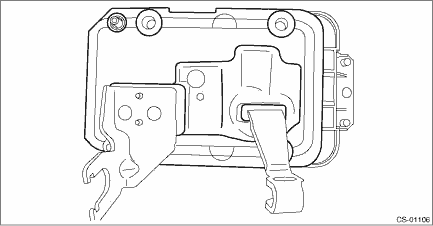

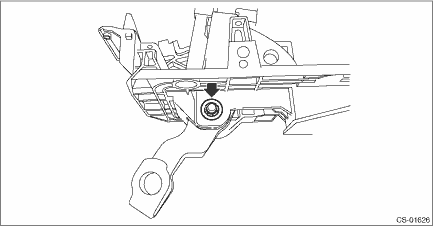

7. Remove the clamp push nut.

NOTE:

Replace the clamp push nut with a new part.

8. Pull out shaft control.

9. Remove the clamp push nut.

NOTE:

Replace the clamp push nut with a new part.

10. Pull out spacer pin guide.

11. Remove the clamp pin.

12. Remove the spacer pin guide.

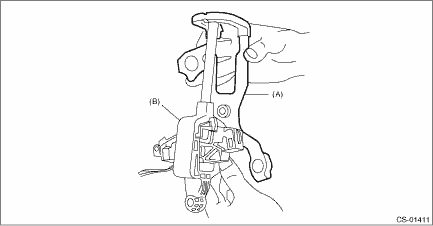

13. Remove the select lever COMPL from the plate COMPL.

14. Remove the arm COMPL.

(A) | Arm COMPL |

(B) | Select lever COMPL |

15. Remove the plate guide from the select lever COMPL.

16. Remove the rod detent and detent spring from the select lever COMPL.

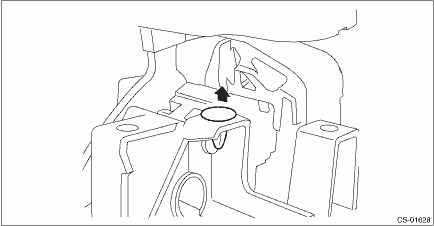

3. INDICATOR ASSY

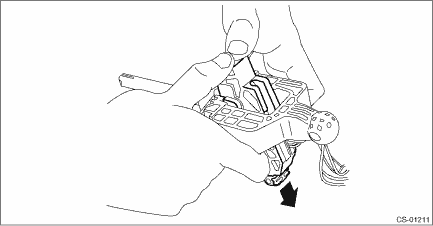

1. Remove the boot assembly from the indicator assembly.

CAUTION:

When removing the boot assembly, be careful not to damage the boot assembly claws and adjacent parts.

Removal

Removal

CONTROL SYSTEMS > Select LeverREMOVAL1. Shift the select lever to “N” range.2. Disconnect the ground cable from battery. NOTE">NOTE:For model with battery sensor, disconnect th ...

Inspection

Inspection

CONTROL SYSTEMS > Select LeverINSPECTION1. Inspect the removed parts by comparing with new parts for deformation, damage and wear. Repair or replace if defective.2. Inspect the select lever assembl ...

Other materials:

After driving

Always check your brakes for effectiveness

immediately after driving in sand,

mud or water. Do this by driving slowly

and stepping on the brake pedal. Repeat

that process several times to dry out the

brake discs and brake pads.

After driving through tall grass, mud,

rocks, sand, riv ...

Removal

FRONT SUSPENSION > Front ArmREMOVAL1. Lift up the vehicle, and then remove the front wheels.2. Remove the under cover - front. Front Under Cover > REMOVAL">3. Remove the front arm assembly.(1) Remove the bolt, and then detach the front support. (Electric power steering model only)(2) ...

General diagnostic table Inspection

CONTROL SYSTEMS > General Diagnostic TableINSPECTIONSymptomsPossible causeCorrective actionSelect leverStarter does not run.Adjust the select cable and inhibitor switch, or inspect the circuit.Back-up light does not illuminate.Adjust the select cable and inhibitor switch, or inspect the circuit.A ...