Subaru Crosstrek Service Manual: Brake warning light does not go off

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Warning Light Illumination Pattern

BRAKE WARNING LIGHT DOES NOT GO OFF

Detecting condition:

• Brake warning light circuit is shorted.

• Defective sensor/connector

• Defective CAN communication

Trouble symptom:

After starting the engine, the brake warning light does not go off even though the parking lever is released.

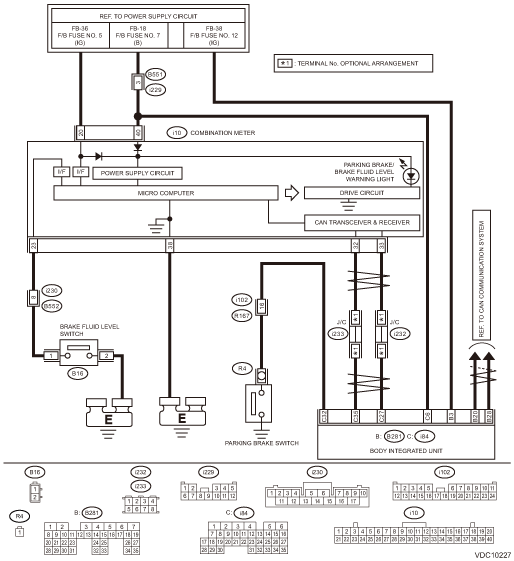

Wiring diagram:

Parking brake / brake fluid level warning light system Parking Brake / Brake Fluid Level Warning Light System > WIRING DIAGRAM">

| STEP | CHECK | YES | NO |

1.CHECK INSTALLATION OF VDCCM&H/U CONNECTOR.

1) Turn the ignition switch to OFF.

2) Check that the VDCCM&H/U connector is inserted until it is locked by clamp.

Is the connector firmly inserted?

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 2.

Insert the VDCCM&H/U connector until it is locked by clamp.

2.READ DTC.

Read the DTC. Read Diagnostic Trouble Code (DTC)">

Is DTC displayed?

Perform the diagnosis according to DTC. List of Diagnostic Trouble Code (DTC)">

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 3.

3.CHECK LAN SYSTEM.

Perform the diagnosis for LAN system. Basic Diagnostic Procedure">

Is there any fault in LAN system?

Perform the diagnosis according to DTC for LAN system. List of Diagnostic Trouble Code (DTC)">

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 4.

4.CHECK BRAKE FLUID AMOUNT.

Check the amount of brake fluid in the reservoir tank of master cylinder.

Does the level of the brake fluid amount fall between the lines of “MAX” and “MIN”?

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 5.

Replenish brake fluid to the specified value.

5.CHECK BRAKE FLUID LEVEL SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the level switch connector (B16) from master cylinder.

3) Measure the resistance between the master cylinder terminals.

Terminals

No. 1 — No. 2:

Is the resistance 1 M? or more?

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 6.

Replace the master cylinder. Master Cylinder">

6.CHECK GROUND SHORT OF HARNESS.

1) Disconnect the connector (i10) from combination meter.

2) Measure the resistance between combination meter connector and chassis ground.

Connector & terminal

(i10) No. 23 — Chassis ground:

Is the resistance 1 M? or more?

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 7.

Repair the harness between combination meter and brake fluid level switch.

7.CHECK PARKING BRAKE SWITCH.

1) Disconnect the connector (R4) from parking brake switch.

2) Release the parking brake.

3) Measure the resistance between parking brake switch terminal and chassis ground.

Is the resistance 1 M? or more?

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 8.

Replace the parking brake switch.

8.CHECK GROUND SHORT OF HARNESS.

1) Disconnect the connector (i84) from body integrated unit.

2) Measure the resistance between body integrated unit connector and chassis ground.

Connector & terminal

(i84) No. 32 — Chassis ground:

Is the resistance 1 M? or more?

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 9.

Repair the harness between body integrated unit and parking brake switch.

9.CHECK POOR CONTACT OF CONNECTOR.

Check for poor contact of all connectors.

Is there poor contact?

Repair the connector.

Warning Light Illumination Pattern > BRAKE WARNING LIGHT DOES NOT GO OFF">Go to Step 10.

10.CHECK COMBINATION METER.

Check the combination meter. Combination Meter System > OPERATION">

Is the check result OK?

• Models without EyeSight

Replace the VDCCM only. VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > REPLACEMENT">

• Models with EyeSight

Replace the VDCCM&H/U. VDC Control Module and Hydraulic Control Unit (VDCCM&H/U)">

Replace the combination meter. Combination Meter">

Vdc off indicator light does not go off

Vdc off indicator light does not go off

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Warning Light Illumination PatternVDC OFF INDICATOR LIGHT DOES NOT GO OFFDetecting condition:• Defective combination meter• Defective CAN ...

Hill start assist warning light does not come on

Hill start assist warning light does not come on

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Warning Light Illumination PatternHILL START ASSIST WARNING LIGHT DOES NOT COME ONDetecting condition:Defective combination meterTrouble symptom:When ...

Other materials:

Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Main RelayREMOVAL1. Disconnect the ground cable from battery.2. Remove the glove box. Glove Box > REMOVAL">3. Remove the main relay from relay block. ...

Assembly

EXTERIOR/INTERIOR TRIM > Door TrimASSEMBLY1. Bend the claws while pushing the weather strip - door INN against the door trim so that there is no gap.CAUTION:Beware of the direction of folding the claws.(a)Rivet(b)Direction of folding claws(c)Claw bending direction: bend forward for LH side, backw ...

Front towing hook

1. Take the towing hook and screwdriver

out of the tool bucket. Take the jack

handle out of the cargo area.

2. Cover the tip of a flat-head screwdriver

with vinyl tape or cloth so that it will not

scratch the bumper. Insert the flat-head

screwdriver into the cutout of the cover

and pry op ...