Subaru Crosstrek Service Manual: Basic inspection

WIRING SYSTEM > Basic Diagnostic Procedure

BASIC INSPECTION

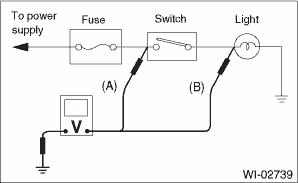

1. VOLTAGE MEASUREMENT

1. Using a voltmeter, connect the negative lead to a good ground point or negative battery terminal and the positive lead to the connector or component terminal.

2. Contact the positive lead of the voltmeter on connector (A). The voltmeter will indicate a voltage.

3. Touch connector (B) with the positive probe. The voltmeter will indicate no voltage.

4. With the test set-up held as it is, turn the switch to ON. The voltmeter will indicate a voltage and, at the same time, the light will illuminate.

5. The circuit is in good order. If a problem such as a light failing to illuminate occurs, use the procedures outlined above to track down the malfunction.

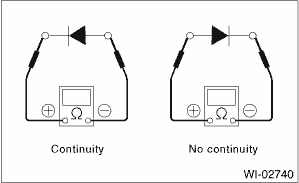

2. CIRCUIT CONTINUITY CHECKS

1. Disconnect the battery terminal or connector so there is no voltage between the check points.

Contact the two leads of an ohmmeter to each of the check points.

If the circuit has diodes, reverse the two leads and check again.

2. Use an ohmmeter to check for diode continuity. When contacting the negative lead to the diode positive side and the positive lead to the negative side, there should be continuity.

When contacting the two leads in reverse, there should be no continuity.

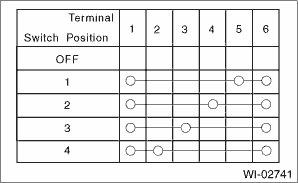

3. The symbol “ —

—  ” indicates that continuity exists between two points or terminals. For example, when a switch position is at “3”, continuity exists among terminals 1, 3 and 6, as shown in the table below.

” indicates that continuity exists between two points or terminals. For example, when a switch position is at “3”, continuity exists among terminals 1, 3 and 6, as shown in the table below.

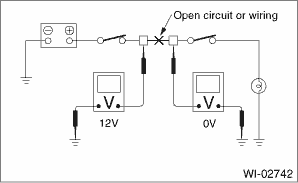

3. HOW TO DETERMINE AN OPEN CIRCUIT

1. WITH VOLTMETER:

An open circuit is determined by measuring the voltage between respective connectors and ground using a voltmeter, starting with the connector closest to the power supply. The power supply must be turned ON so that current flows in the circuit. If voltage is not present between a particular connector and ground, the circuit between that connector and the previous connector is open.

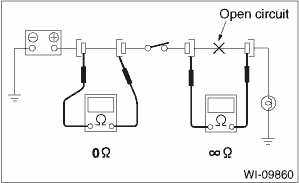

2. WITH OHMMETER:

Disconnect all connectors affected, and check continuity in the wiring between adjacent connectors. When the ohmmeter indicates “infinite”, the wiring is open.

4. HOW TO DETERMINE A SHORT CIRCUIT

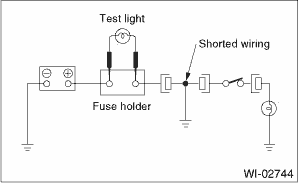

1. WITH TEST LIGHT:

Connect a test light (rated at approx. 3 watts) in place of the blown fuse and allow current to flow through the circuit. Disconnect one connector at a time from the circuit. Starting with the one located farthest from the power supply. If the test light goes out when a connector is disconnected, the wiring between that connector and the next connector (farther from the power supply) is shorted.

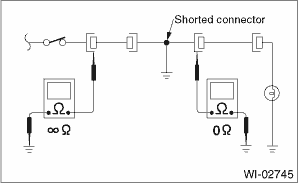

2. WITH OHMMETER:

Disconnect all affected connectors, and check continuity between each connector and ground. When the ohmmeter indicates continuity between a particular connector and a ground, that connector is shorted.

Connector symbol in wiring harness

Connector symbol in wiring harness

WIRING SYSTEM > Basic Diagnostic ProcedureCONNECTOR SYMBOL IN WIRING HARNESSA number of connector symbols are used in each wiring diagram to easily identify the wiring harness connectors. ...

How to read wiring diagrams

How to read wiring diagrams

WIRING SYSTEM > Basic Diagnostic ProcedureHOW TO READ WIRING DIAGRAMS1. WIRING DIAGRAMThe wiring diagram of each system is illustrated so that you can understand the path through which the electric ...

Other materials:

Removal

POWER ASSISTED SYSTEM (POWER STEERING) > Steering WheelREMOVALCAUTION:Before handling the airbag system components, always refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">1. Set the tire to the straight ...

Gross Vehicle Weight (GVW) and Gross Vehicle Weight Rating (GVWR)

Gross Vehicle Weight

The Gross Vehicle Weight (GVW) must

never exceed the Gross Vehicle Weight

Rating (GVWR).

Gross Vehicle Weight (GVW) is the

combined total of the weight of the vehicle,

driver, passengers, luggage, trailer hitch,

trailer tongue load and any other optional

equipment ...

Dtc b1803 short in driver s airbag (to +b)

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B1803 SHORT IN DRIVER’S AIRBAG (TO +B)Diagnosis start condition:Ignition voltage is 10 V to 16 V.DTC detecting condition:• Airbag main harness circuit is shorted to power supply.• Airbag module harness (driver&r ...