Subaru Crosstrek Service Manual: Assembly

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Forward Clutch Assembly

ASSEMBLY

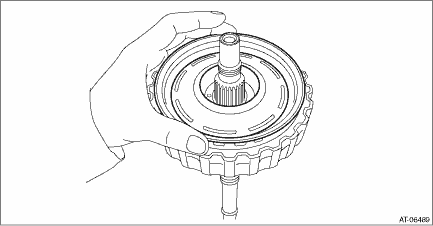

1. FORWARD CLUTCH ASSEMBLY

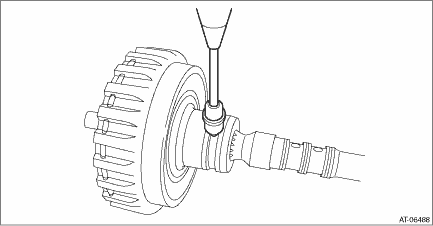

1. Install the forward clutch piston to forward clutch drum.

NOTE:

• Apply CVTF to the seal of forward clutch piston.

• Insert it all the way to the end.

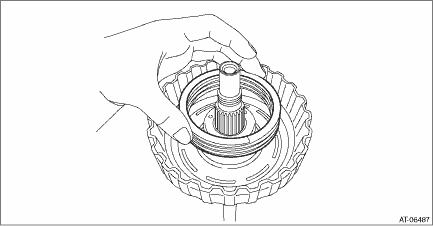

2. Install the return spring.

3. Install the chamber COMPL.

NOTE:

Apply CVTF to the sealing area of chamber COMPL.

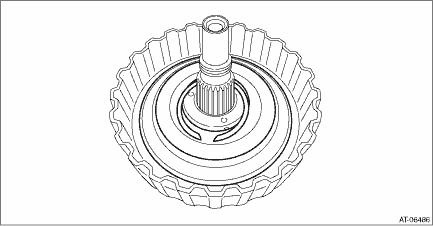

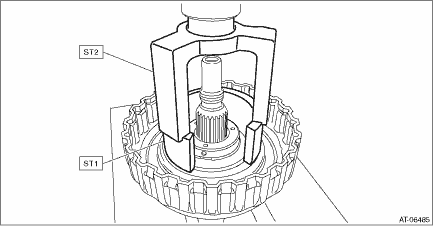

4. Compress the return spring using the ST to install the snap ring.

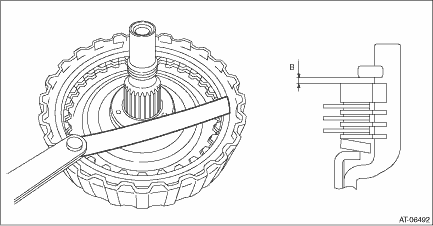

| ST1 18762AA010 | COMPRESSOR SPECIAL TOOL |

| ST2 398673600 | COMPRESSOR |

5. Check the operation of forward clutch piston by blowing compressed air intermittently from forward clutch carrier hole.

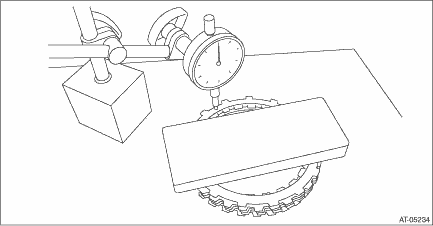

6. Place the driven plate, drive plate and retaining plate neatly in this order on surface table.

7. Set the dial gauge to retaining plate, and read its scale.

NOTE:

The value, which is read in the gauge at this time, is zero point.

8. Scale and record the weight “Z” of a flat board which will be put on retaining plate.

NOTE:

• Use a stiff board which does not bend against load as a flat board to be put on retaining plate.

• Use a flat board weighing less than 52 N (5.3 kgf, 11.7 lb).

9. Put the flat board on retaining plate.

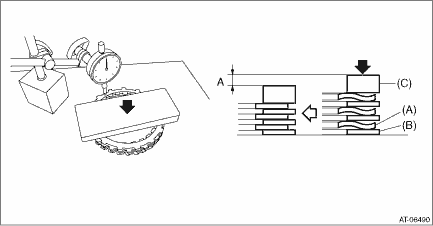

10. Using the following formula, read the push/pull gauge and calculate “N”.

N = 52 N (5.3 kgf, 11.7 lb) − Z

52 N (5.3 kgf, 11.7 lb) : Load applied to clutch plate

Z: Flat board weight

11. Press the center of retaining plate by applying a force of “N” using push/pull gauge, and then measure and record the compression amount “A”.

NOTE:

Measure at four points with a 90° interval and calculate the average.

(A) | Driven plate |

(B) | Drive plate |

(C) | Retaining plate |

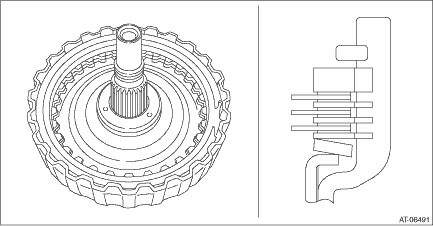

12. Install the dish plate, drive plate, driven plate, retaining plate and snap ring to the forward clutch carrier.

NOTE:

Install the dish plate in the correct direction.

13. Measure and record the clearance “B” between the retaining plate and snap ring.

14. Piston stroke calculation

Calculate with A and B dimensions recorded before.

If it exceeds the limit, replace with a new drive plate and adjust within the initial standard value.

S mm (in) = A + B

S: Piston stroke

A: Compression amount of drive plate and dish plate

B: Clearance between retaining plate and snap ring

Initial standard:

1.0 — 1.4 mm (0.040 — 0.055 in)

Limit thickness:

1.6 mm (0.063 in)

Retaining plate | |

Part No. | Thickness mm (in) |

31567AB760 | 4.2 (0.165) |

31567AB770 | 4.4 (0.173) |

31567AB780 | 4.6 (0.181) |

31567AB790 | 4.8 (0.189) |

31567AB830 | 5.0 (0.197) |

2. PLANETARY CARRIER ASSY

NOTE:

Assemble in the reverse order of disassembly.

3. INTERNAL GEAR

NOTE:

Assemble in the reverse order of disassembly.

Removal

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Forward Clutch AssemblyREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Remove the ...

Disassembly

Disassembly

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Forward Clutch AssemblyDISASSEMBLY1. FORWARD CLUTCH ASSEMBLY1. Remove the snap ring.2. Remove the retaining plate, drive plate, driven plate and dish pla ...

Other materials:

Dtc p0198 engine oil temperature sensor "a" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0198 ENGINE OIL TEMPERATURE SENSOR "A" CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Hard to start• Improper idling• Poor driving performanc ...

Inspection

VEHICLE DYNAMICS CONTROL (VDC) > Yaw Rate and G SensorINSPECTION1. YAW RATE & LONGITUDINAL G AND LATERAL G SENSOR SIGNALSTEPCHECKYESNO1.CHECK YAW RATE & G SENSOR.1) Check the installation condition of the VDC control module & hydraulic control module (VDCCM&H/U).2) Using the Subar ...

Inspection

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF) > Sunroof Control SystemINSPECTIONSymptomsInspection stepsWater leakage(1) Check the roof panel and the lid assembly - sunroof for improper or poor sealing.(2) Check the drain tube - sunroof for clogging.(3) Check the joints of the rail assembly - sunroof f ...