Subaru Crosstrek Service Manual: Removal

MECHANICAL(H4DO) > Timing Chain Assembly

REMOVAL

1. TIMING CHAIN RH

NOTE:

When replacing a single part, perform the work with the engine assembly installed to body.

1. Remove the chain cover. Chain Cover > REMOVAL">

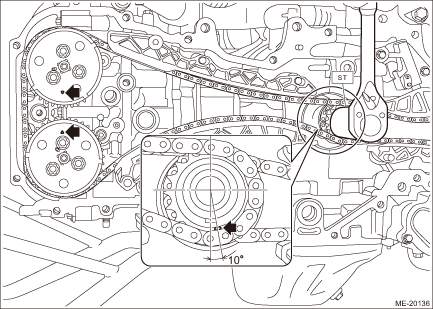

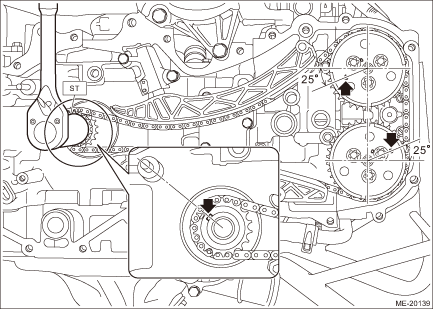

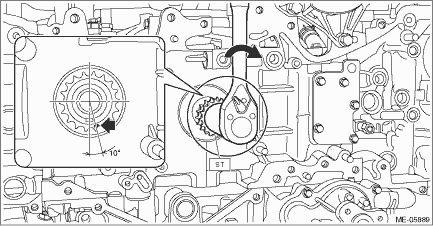

2. Using ST and by turning the crankshaft, align the alignment marks of crank sprocket, intake cam sprocket RH and exhaust cam sprocket RH to the positions as shown in the figure.

NOTE:

If the alignment marks are aligned to the positions as shown in the figure, the crankshaft key is located at six o’clock position.

| ST 18252AA000 | CRANKSHAFT SOCKET |

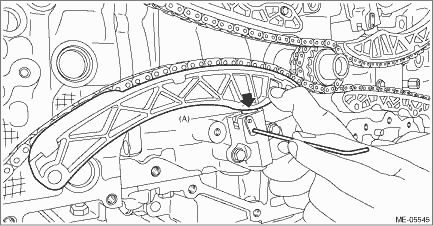

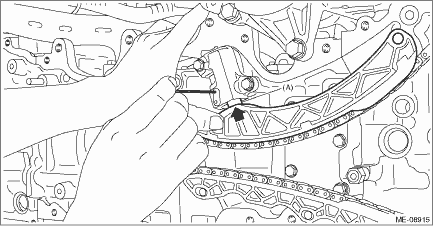

3. Push down the chain lever tensioner RH, and with a 2.5 mm (0.098 in) dia. stopper pin or a 2.5 mm dia. hex wrench inserted into the stopper pin hole in the chain tensioner RH, secure the plunger (A).

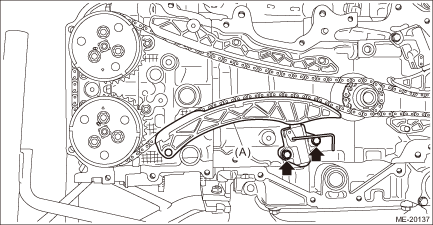

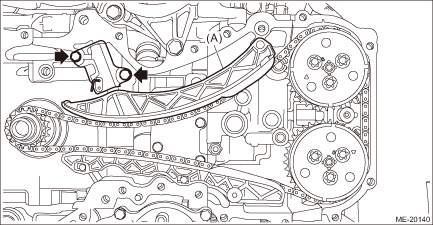

4. Remove the chain tensioner RH, and remove the chain tensioner lever RH (A).

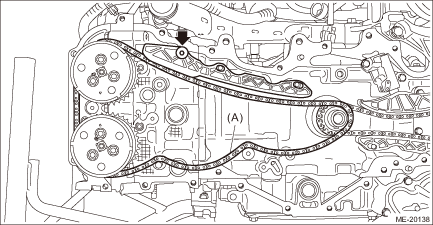

5. Remove the chain guide RH, and remove the timing chain RH (A).

CAUTION:

• If the timing chain RH is not installed, the intake camshaft RH and exhaust camshaft RH are kept at zero-lift position. All cams on the camshaft are not pressing down the roller rocker arm (intake valve and exhaust valve). (Under this condition, all valves remain unlifted.)

• Intake camshaft RH and exhaust camshaft RH can be independently rotated with the timing chain RH removed. When the intake valve and exhaust valve lift at the same time, the valve heads contact each other and valve stem may bend. Do not turn it to the outside of range of zero-lift (in range where it can be turned lightly by hand).

NOTE:

To avoid mixing with LH side, keep the removed part in order.

2. TIMING CHAIN LH

1. Remove the timing chain RH. Timing Chain Assembly > REMOVAL">

2. Using ST and by turning the crankshaft, align the alignment marks of crankshaft key, intake cam sprocket LH and exhaust cam sprocket LH to the positions as shown in the figure.

| ST 18252AA000 | CRANKSHAFT SOCKET |

3. Push down the chain lever tensioner LH, and with a 1.3 mm (0.05 in) dia. stopper pin or a 1.3 mm dia. hex wrench inserted into the stopper pin hole in the chain tensioner LH, secure the plunger (A).

4. Remove the chain tensioner LH, and remove the chain tensioner lever LH (A).

5. Remove the O-ring from the cylinder block LH.

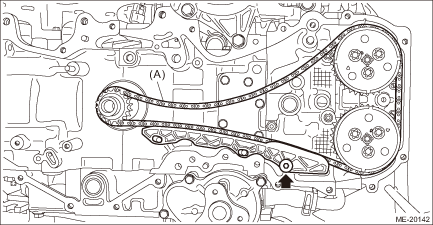

6. Remove the chain guide LH, and remove the timing chain LH (A).

CAUTION:

• If the timing chain LH is not installed, the exhaust camshaft LH is kept at zero-lift position. All cams on the exhaust camshaft LH are not pressing down the roller rocker arm (exhaust valve). (Under this condition, exhaust valves remain unlifted.)

• Intake camshaft LH is kept at lift position. All cams on the intake camshaft LH are pressing down the roller rocker arm (intake valve). (Under this condition, intake valves remain lifted.)

• Intake camshaft LH and exhaust camshaft RH can be independently rotated with the timing chain LH removed. When the exhaust camshaft LH is turned, the valve heads contact each other and valve stem may bend as described in above. Do not turn the exhaust camshaft LH to the outside of range of zero-lift (in range where it can be turned lightly by hand).

• #1 piston and #4 piston are located near TDC. If the intake camshaft LH is turned, the valve and the piston may contact and valve stem may bend. Do not turn the intake camshaft LH at this time.

NOTE:

To avoid mixing with RH side, keep the removed part in order.

7. Using ST and by turning the crankshaft approximately 200° clockwise, align the alignment marks of crank sprocket to the positions as shown in the figure.

CAUTION:

• This procedure is required to prevent the valve and piston contacting with each other, by moving the all pistons to the middle of the cylinders.

• Never turn counterclockwise because the valve and piston may contact. Counterclockwise turn is allowed only when adjusting precisely the alignment marks, after turning the crank sprocket alignment mark clockwise near the position as shown in the figure.

| ST 18252AA000 | CRANKSHAFT SOCKET |

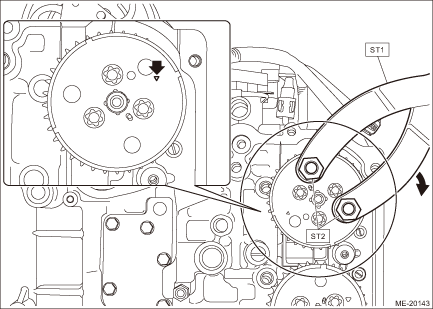

8. Using ST and by turning the intake cam sprocket LH approximately 180°, align the alignment marks of intake cam sprocket LH to the positions (zero-lift position) as shown in the figure.

CAUTION:

• After this work, when the intake valve and exhaust valve lift at the same time, the valve heads contact each other and valve stem may bend. Do not turn the intake camshaft LH and exhaust camshaft LH to the outside of range of zero-lift (in range where it can be turned lightly by hand).

• Perform the operation carefully since the ST comes off easily.

| ST1 18355AA000 | PULLEY WRENCH |

| ST2 18334AA020 | PULLEY WRENCH PIN SET |

Inspection

Inspection

MECHANICAL(H4DO) > Timing Chain AssemblyINSPECTION1. Check the timing chain, chain guide, chain tensioner lever and chain tensioner for deformation, cracks or other damages.2. Check the chain guide ...

Installation

Installation

MECHANICAL(H4DO) > Timing Chain AssemblyINSTALLATION1. TIMING CHAIN LHNOTE:• Be careful that the foreign matter is not into or onto the assembled component during installation.• Apply e ...

Other materials:

Removal

HVAC SYSTEM (HEATER, VENTILATOR AND A/C) > Power Transistor (Auto A/C Model)REMOVAL1. Disconnect the ground cable from battery. NOTE">2. Remove the glove box. Glove Box > REMOVAL">3. Remove the screws and remove the duct - foot RH.NOTE:Remove the connector and harness clip of ...

Inspection

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS) > General DescriptionINSPECTIONBefore performing diagnosis, check the following item which might affect the quality of the tire pressure monitoring system.1. TIRE• Inspect that the tire pressure is within the specification while the tire is cool ...

Adjustment

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission CaseADJUSTMENTNOTE:When replacing the transmission case with a new part, perform the following check and adjustment for the selection.• Select the transfer driven gear shim. Transfer Clutch > ADJUSTMENT">• Select the ...