Subaru Crosstrek Service Manual: Removal

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > EGR Cooler

REMOVAL

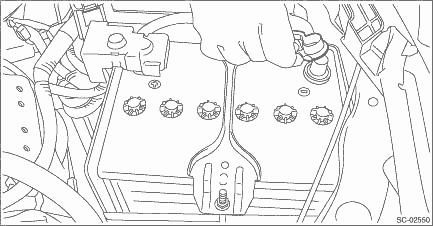

1. Disconnect the ground cable from battery.

2. Drain engine coolant. Engine Coolant > REPLACEMENT">

3. Remove the center exhaust pipe. Center Exhaust Pipe > REMOVAL">

4. Lower the vehicle.

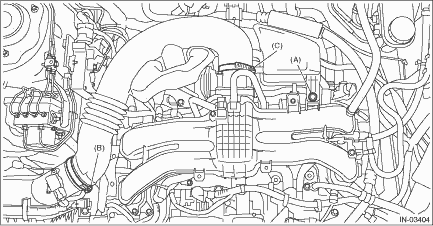

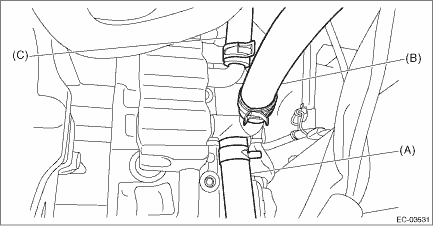

5. Remove the clip (A), and loosen the clamps (B) and (C) securing the air intake boot.

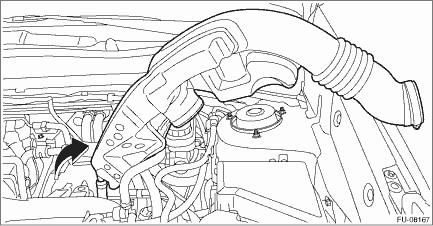

6. Remove the air intake boot from the air cleaner case (rear) and throttle body, and move the air intake boot aside so that it does not interfere with the work.

7. Remove the clip holding the air breather hose to the engine rear hanger. (MT model)

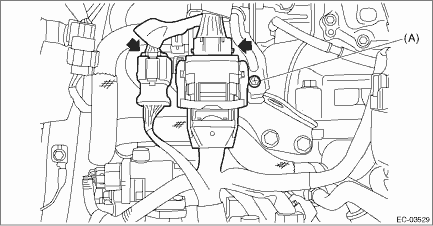

8. Disconnect the engine harness connector.

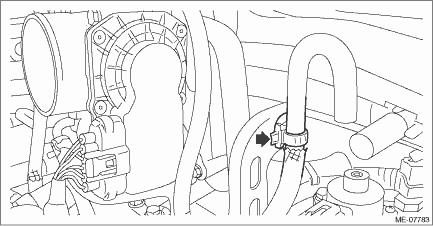

(1) Remove the bolt (A) securing the bulkhead harness connector bracket.

(2) Disconnect the bulkhead harness connector from the engine harness connector (black) and engine harness connector (brown).

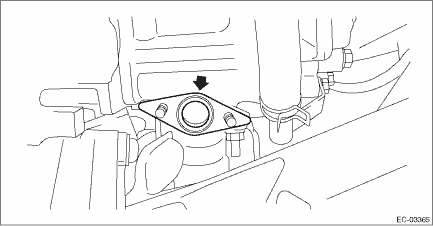

9. Remove the engine rear hanger.

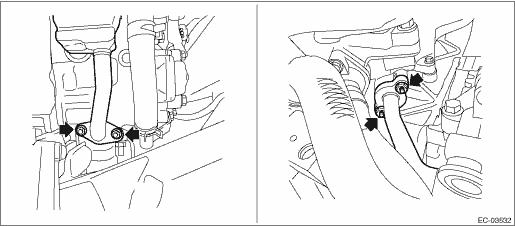

10. Disconnect the engine coolant hose (A), engine coolant hose (B) (CVT model) and engine coolant hose (C) from the EGR cooler.

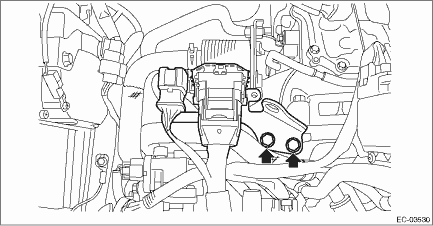

11. Remove the nuts which secure the EGR cooler to the cylinder head RH.

12. Remove the nuts which secure the EGR cooler to the EGR control valve.

13. Remove the gasket from the stud bolt.

Inspection

Inspection

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > EGR CoolerINSPECTION1. Check that the EGR cooler has no deformation, cracks or other damages.2. Check that the hose has no cracks, damage or ...

Installation

Installation

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > EGR CoolerINSTALLATION1. Set the gasket to the stud bolt.NOTE:Use a new gasket.2. Temporarily tighten the bolts securing the EGR cooler to t ...

Other materials:

Wiring diagram

INSTRUMENTATION/DRIVER INFO > Combination Meter SystemWIRING DIAGRAMRefer to “Combination Meter System” in the wiring diagram.– Models with normal meters: Combination Meter System > WIRING DIAGRAM">– Model with color TFT meter: Combination Meter System > WIRING D ...

Dtc b2a0e mute line circuit

TELEMATICS SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B2A0E MUTE LINE CIRCUITDiagnosis start condition:When ignition switch is ON.DTC detecting condition:Any of the following conditions occurs continuously for five seconds or more after the ignition switch i ...

Installation

HVAC SYSTEM (HEATER, VENTILATOR AND A/C) > Expansion ValveINSTALLATIONCAUTION:Replace the O-rings with new parts, and then apply compressor oil.1. Install each part in the reverse order of removal.Tightening torque:Heater and cooling unit: General Description > COMPONENT">Air conditio ...