Subaru Crosstrek Service Manual: Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission Harness

REMOVAL

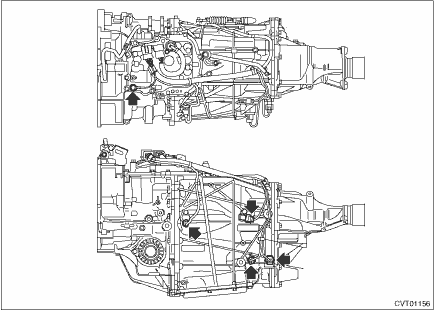

1. INHIBITOR HARNESS

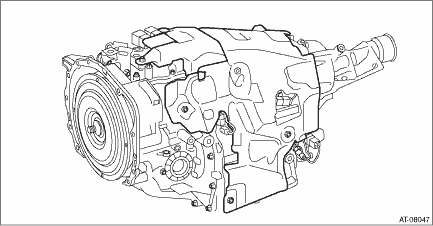

1. Remove the transmission from the vehicle. Automatic Transmission Assembly > REMOVAL">

2. Remove the transmission case cover.

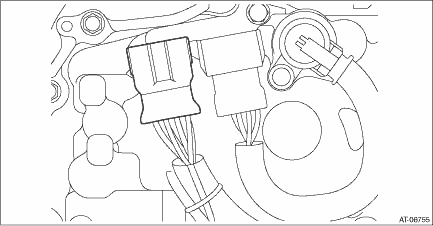

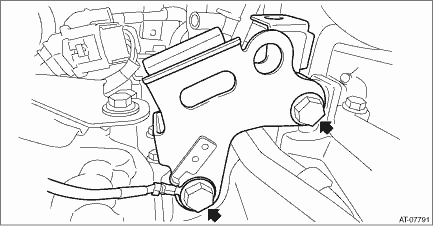

3. Remove the harness connector from the ground terminal, turbine speed sensor, primary speed sensor, secondary speed sensor and secondary pressure sensor.

4. Remove the harness connector from inhibitor switch.

5. Remove the inhibitor harness connector from the transmission harness stay.

6. Remove the harness clip from the transmission, and remove the inhibitor harness.

2. TRANSMISSION HARNESS

1. Disconnect the ground cable from battery. NOTE">

NOTE:

For model with battery sensor, disconnect the ground terminal from battery sensor.

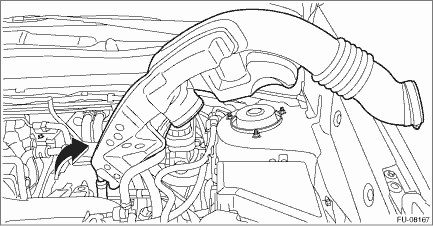

2. Remove the clip (A) from the air intake boot.

3. Loosen the clamp (B) connecting the air intake boot and air cleaner case (rear).

4. Loosen the clamp (C) which connects the air intake boot and throttle body.

5. Remove the air intake boot from the throttle body, and move it to the left side wheel apron.

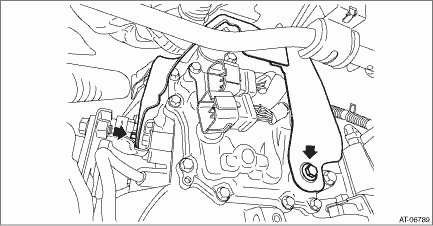

6. Disconnect the following connectors.

• Transmission harness connectors

• Inhibitor harness connector

• Transmission radio ground terminal

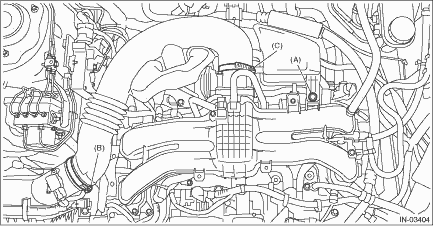

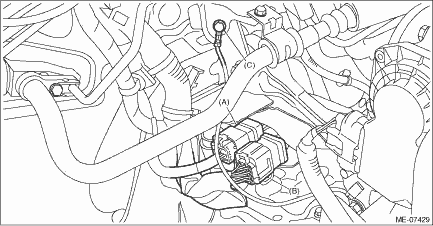

(A) | Transmission harness connectors |

(B) | Inhibitor harness connector |

(C) | Transmission radio ground terminal |

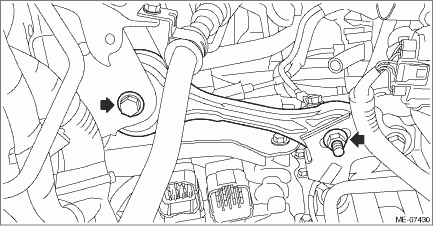

7. Remove the pitching stopper.

8. Remove the air breather hose from the pitching stopper bracket, and then remove the pitching stopper bracket and transmission radio ground cord.

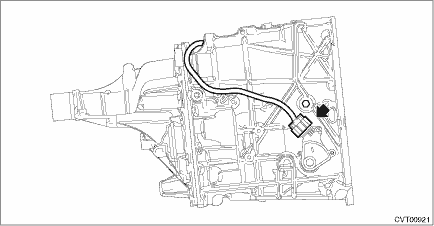

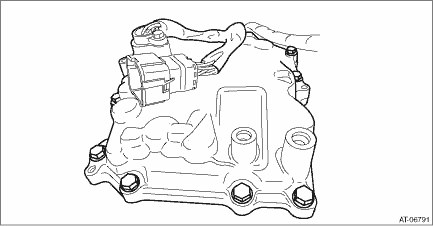

9. Remove the transmission case cover.

10. Remove the transmission harness stay and ground terminal.

11. Remove the transmission harness connector from the harness stay.

12. Clean the transmission exterior.

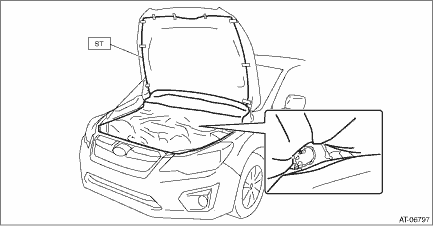

13. Set the ST on the vehicle.

| ST 18761AA010 | SHEET SPECIAL TOOL |

14. Remove the valve cover and gasket.

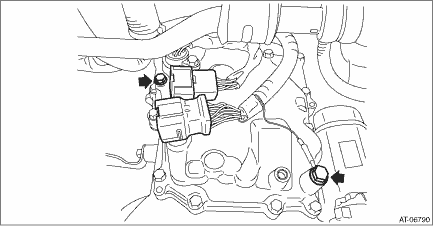

15. Remove the transmission harness connector from the control valve body.

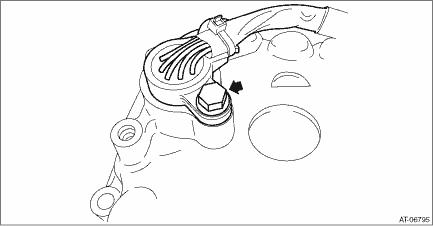

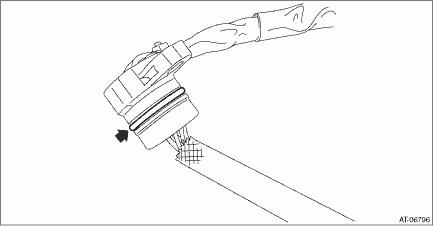

16. Remove the transmission harness from the valve cover.

17. Remove the O-ring from the transmission harness.

Inspection

Inspection

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission HarnessINSPECTION1. Visually check the harness and connector for damage or crack.2. Check the harness terminal for rust, disconnection or po ...

Installation

Installation

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Transmission HarnessINSTALLATION1. INHIBITOR HARNESSInstall in the reverse order of removal.NOTE:Install the transmission ground terminal in the directio ...

Other materials:

Removal

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyREMOVAL1. Disconnect the ground cable from battery.2. Lift up the vehicle.3. Remove the rear exhaust pipe. Rear Exhaust Pipe > REMOVAL">4. Remove the propeller shaft. Propeller Shaft > REMOVAL"& ...

Removal

POWER ASSISTED SYSTEM (POWER STEERING) > Electric Power Steering GearboxREMOVALCAUTION:• The power steering control module continues to operate after the engine stops and calculate the temperature in the control module. Therefore, before starting service of the power steering system which r ...

Dtc p0137 o2 sensor circuit low voltage bank 1 sensor 2

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0137 O2 SENSOR CIRCUIT LOW VOLTAGE BANK 1 SENSOR 2DTC detecting condition:Detected when two consecutive driving cycles with fault occur.CAUTION:After servicing or replacing faulty parts, perform Clear Memory ...