Subaru Crosstrek Service Manual: Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Transfer Case and Extension Case Assembly

INSTALLATION

1. Clean the mating surfaces of the transmission case, transfer case and extension case.

2. Apply a coat of grease to the taper roller bearing (transfer case side) of transfer driven gear and the roller rolling surface of the taper roller bearing (extension case side).

Grease:

NICHIMOLY N-130 or equivalent

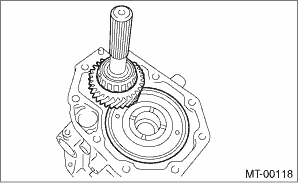

3. Install the center differential and the transfer driven gear.

4. Install the taper roller bearing (extension case side) outer race to the transfer driven gear.

5. While pressing the taper roller bearing (extension case side) outer race horizontally, rotate the transfer driven gear for ten turns.

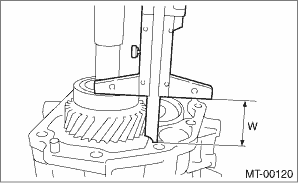

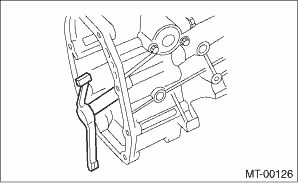

6. Measure the height “W” between transfer case and taper roller bearing (transfer case side) on the transfer driven gear.

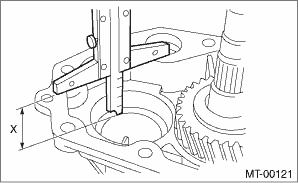

7. Measure the depth “X” of taper roller bearing insertion part of the extension case.

NOTE:

Measure while the taper roller bearing (extension case side) outer race, dish plate and adjusting washer are removed.

8. Calculate the adjusting washer thickness “t” using the following calculation.

t = X − W − (1.715 — 1.765 mm (0.686 — 0.706 in))

X: Depth of taper roller bearing insertion part of extension case

W: Height between transfer case and taper roller bearing (transfer case side) on transfer driven gear

9. Select the adjusting washer with the nearest value in the following table.

Adjusting washer (61 ? 50 ? t) | |

Part No. | Thickness mm (in) |

803050060 | 0.50 (0.0197) |

803050061 | 0.55 (0.0217) |

803050062 | 0.60 (0.0236) |

803050063 | 0.65 (0.0256) |

803050064 | 0.70 (0.0276) |

803050065 | 0.75 (0.0295) |

803050066 | 0.80 (0.0315) |

803050067 | 0.85 (0.0335) |

803050068 | 0.90 (0.0354) |

803050069 | 0.95 (0.0374) |

803050070 | 1.00 (0.0394) |

803050071 | 1.05 (0.0413) |

803050072 | 1.10 (0.0433) |

803050073 | 1.15 (0.0453) |

803050074 | 1.20 (0.0472) |

803050075 | 1.25 (0.0492) |

803050076 | 1.30 (0.0512) |

803050077 | 1.35 (0.0531) |

803050078 | 1.40 (0.0551) |

803050079 | 1.45 (0.0571) |

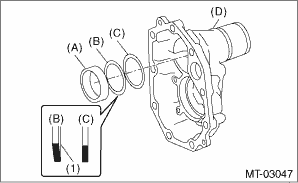

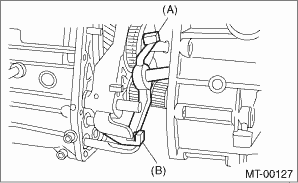

10. Install the selected adjusting washer, dish plate and taper roller bearing (extension case side) outer race.

NOTE:

Make sure the dish plate is installed in the proper direction.

(A) | Taper roller bearing (extension case side) outer race |

(B) | Dish plate |

(C) | Adjusting washer |

(D) | Extension case |

(1) | Paint side |

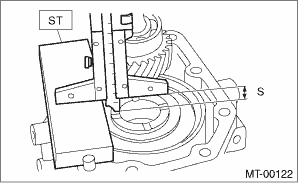

11. Measure the depth “S” between the transfer case + ST and the center differential.

| ST 398643600 | GAUGE |

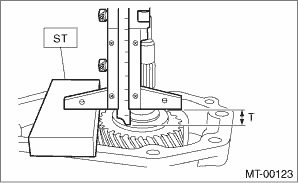

12. Measure the height “T” between the extension case + ST and the transfer drive gear.

| ST 398643600 | GAUGE |

13. Calculate the adjusting washer thickness “U” using the following calculation.

U = S + T − 30 mm (1.18 in) − (0.15 — 0.35 mm (0.0059 — 0.0138 in))

S: Depth between the transfer case + ST and the center differential

T: Height between the extension case + ST and the transfer drive gear

30 mm (1.18 in): Thickness of ST (? 2 pieces)

0.15 — 0.35 mm (0.0059 — 0.0138 in): Clearance

14. Select a suitable adjusting washer in the following table.

Clearance:

0.15 — 0.35 mm (0.0059 — 0.0138 in)

Adjusting washer | |

Part No. | Thickness mm (in) |

803036050 | 0.9 (0.035) |

803036054 | 1.0 (0.039) |

803036051 | 1.1 (0.043) |

803036055 | 1.2 (0.047) |

803036052 | 1.3 (0.051) |

803036056 | 1.4 (0.055) |

803036053 | 1.5 (0.059) |

803036057 | 1.6 (0.063) |

803036058 | 1.7 (0.067) |

803036080 | 1.8 (0.071) |

803036081 | 1.9 (0.075) |

15. Install the adjusting washer to center differential.

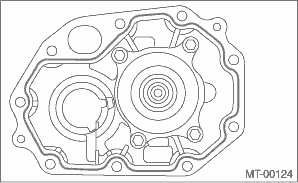

16. Apply an appropriate amount of liquid gasket.

Liquid gasket:

THREE BOND 1215B or equivalent

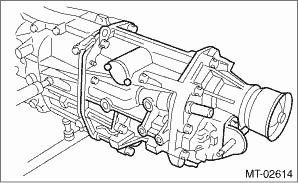

17. Install the extension case assembly.

Tightening torque:

40 N·m (4.1 kgf-m, 29.5 ft-lb)

18. Install the shifter arm.

NOTE:

Apply transmission gear oil to the oil seal lips.

19. Attach the gasket.

NOTE:

Use a new gasket.

20. Hang the shifter arm on 3rd-4th fork rod.

(A) | Shifter arm |

(B) | 3rd-4th fork rod |

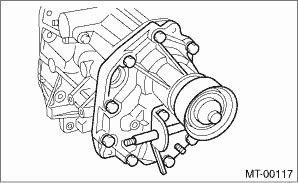

21. Install the transfer case together with the extension case assembly.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

22. Install the back-up light switch and the neutral position switch. Switches and Harness > INSTALLATION">

23. Install the manual transmission assembly to the vehicle. Manual Transmission Assembly > INSTALLATION">

Disassembly

Disassembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Transfer Case and Extension Case AssemblyDISASSEMBLY1. TRANSFER CASE1. Remove the reverse check sleeve assembly. Reverse Check Sleeve > REMOVAL" ...

Other materials:

Removal

EXTERIOR/INTERIOR TRIM > Front Under CoverREMOVAL1. Lift up the vehicle.2. Remove the bolts and clips, and remove the under cover - front.(1)Under cover - front(2)Mud guard - front(3)Spacer - under cover ...

Inspection

SECURITY AND LOCKS > Keyless Access Outdoor AntennaINSPECTION1. Check the setting by performing Keyless access system check using the Subaru Select Monitor. Keyless Access System Check > OPERATION">2. Disconnect the Subaru Select Monitor. While bringing the access key, operate the tou ...

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Primary Speed SensorREMOVALCAUTION:Be sure to prevent water or oil from contacting the connector terminal of primary speed sensor. If adhesion occurs, replace with a new part.1. Remove the transmission assembly. Automatic Transmission Assembly > REM ...