Subaru Crosstrek Service Manual: Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Drive Pinion Shaft Assembly

INSTALLATION

1. Remove the front differential assembly.

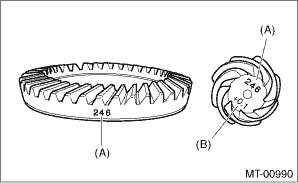

2. Hypoid gear set match mark/No.: The number (A) on top of the drive pinion, and the number on the hypoid driven gear are set numbers for the two gears. Use a pair having the same numbers.

The figure (B) below shows a number for shim adjustment. If no number is shown, the value is zero.

(A) | Set number |

(B) | Number for shim adjustment |

3. Place the drive pinion shaft assembly on transmission main case RH without shim and tighten the bearing mounting bolts.

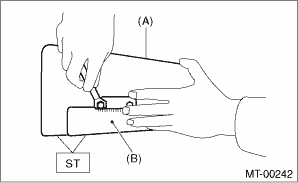

4. Perform the adjustment of ST.

(1) Loosen the two bolts and adjust so that the scale indicates 0.5 correctly when the plate end and the scale end are on the same level.

| ST 499917500 | DRIVE PINION GAUGE ASSY |

(A) | Plate |

(B) | Scale |

(2) Tighten the two bolts.

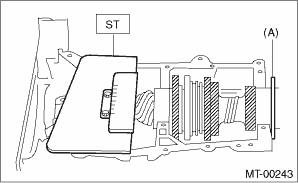

5. Position the ST by inserting the knock pin of ST into the knock hole of transmission case.

| ST 499917500 | DRIVE PINION GAUGE ASSY |

6. Slide the drive pinion gauge scale with finger tip and read the value at the point where it matches with the end face of drive pinion.

| ST 499917500 | DRIVE PINION GAUGE ASSY |

(A) | Adjust the clearance to zero without drive pinion shims. |

7. The thickness of drive pinion shims shall be determined by adding the value indicated on drive pinion to the value indicated on the ST. (Add if the number on drive pinion is prefixed by +, and subtract if the number is prefixed by −.)

| ST 499917500 | DRIVE PINION GAUGE ASSY |

8. Select one to three drive pinion shim(s) from the following table for the value determined as described above, and take the shim(s) whose thickness is closest to the said value.

Drive pinion shim | |

Part No. | Thickness mm (in) |

32295AA031 | 0.150 (0.0059) |

32295AA041 | 0.175 (0.0069) |

32295AA051 | 0.200 (0.0079) |

32295AA061 | 0.225 (0.0089) |

32295AA071 | 0.250 (0.0098) |

32295AA081 | 0.275 (0.0108) |

32295AA091 | 0.300 (0.0118) |

32295AA101 | 0.500 (0.0197) |

9. Install the front differential assembly. Front Differential Assembly > INSTALLATION">

10. Fit the transmission case knock pin to the knock pin hole of the roller bearing and install the drive pinion shaft assembly.

11. Install the main shaft assembly. Main Shaft Assembly > INSTALLATION">

12. Check each shifter fork. Shifter Fork and Rod > INSPECTION">

13. Install the transmission case. Transmission Case > INSTALLATION">

14. Install the transfer case together with the extension case assembly. Transfer Case and Extension Case Assembly > INSTALLATION">

15. Install the manual transmission assembly to the vehicle. Manual Transmission Assembly > INSTALLATION">

Inspection

Inspection

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Drive Pinion Shaft AssemblyINSPECTIONDisassembled parts should be washed with cleaning solvent first, then inspected carefully.1. BearingReplace the bear ...

Other materials:

Dtc p0400 egr "a" flow

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0400 EGR "A" FLOWDTC detecting condition:Detected when two consecutive driving cycles with fault occur.Trouble symptom:• Movement performance problem when engine is low speed• Improper i ...

Caution

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS) > General DescriptionCAUTION1. The occupant detection system (passenger seat only) control module and the occupant detection sensor are fixed to the seat cushion frame. Never remove the occupant detection control module or the occupant detection sensor from ...

Dtc u0101 lost communication with tcm

LAN SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0101 LOST COMMUNICATION WITH TCMDTC detecting condition:No data is received from TCM.Trouble symptom:Cooperation control with transmission is not performed.STEPCHECKYESNO1.CHECK PERFORMING OF BASIC DIAGNOSTIC P ...