Subaru Crosstrek Service Manual: Installation

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Engine Wiring Harness

INSTALLATION

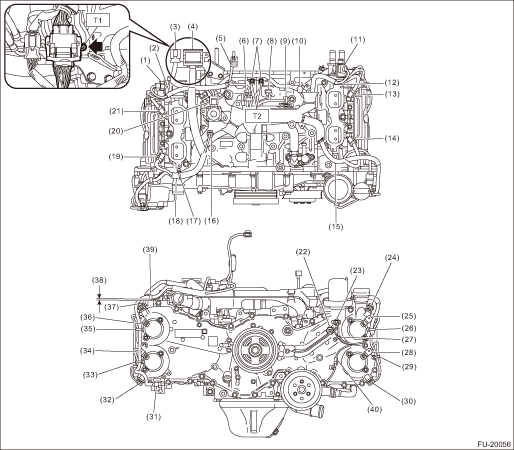

1. Route the engine wiring harness around the engine and connect connectors.

• Structural diagram 1

(1) | Tumble generator valve actuator RH | |

(2) | Be careful of pinching when installing the intake manifold. | |

(3) | Engine harness connector (16P) | |

(4) | Engine harness connector (54P) | |

(5) | Throttle position sensor connector | |

(6) | Manifold absolute pressure sensor connector | |

(7) | Engine ground (2 locations) | |

(8) | Crankshaft position sensor | |

(9) | Knock sensor | |

(10) | Purge control solenoid valve connector | |

(11) | Tumble generator valve actuator LH | |

(12) | Be careful of pinching when installing the intake manifold. | |

(13) | Fuel injector (#4) | |

(14) | Fuel injector (#2) | |

(15) | Be careful of pinching when installing the intake manifold and A/C bracket. | |

(16) | Engine coolant temperature sensor | |

(17) | Secure the clip to the screw hole. | |

(18) | Be careful of pinching when installing the intake manifold. | |

(19) | Fuel injector (#1) | |

(20) | EGR valve | |

(21) | Fuel injector (#3) | |

(22) | Oil pressure switch | |

(23) | Engine oil temperature sensor | |

(24) | Intake camshaft position sensor LH | |

(25) | Intake oil control solenoid LH | |

(26) | Secure the clip to the screw hole. | |

(27) | Secure the clip to the screw hole. | |

(28) | Exhaust oil control solenoid LH | |

(29) | Secure the clip to the screw hole. | |

(30) | Exhaust camshaft position sensor LH | |

(31) | Secure the clip to the oval hole. | |

(32) | Exhaust camshaft position sensor RH | |

(33) | Secure the clip to the screw hole. | |

(34) | Exhaust oil control solenoid RH | |

(35) | Secure the clip to the screw hole. | |

(36) | Intake oil control solenoid RH | |

(37) | Intake camshaft position sensor RH | |

(38) | Maximum of 0 — 2 mm (0 — 0.079 in) gap is allowed. | |

(39) | Secure the clip to the screw hole. | |

(40) | Oil level switch connector | |

Tightening torque: N·m (kgf-m, ft-lb) | ||

T1: | 7.5 (0.8, 5.5) | |

T2: | 19 (1.9, 14.0) | |

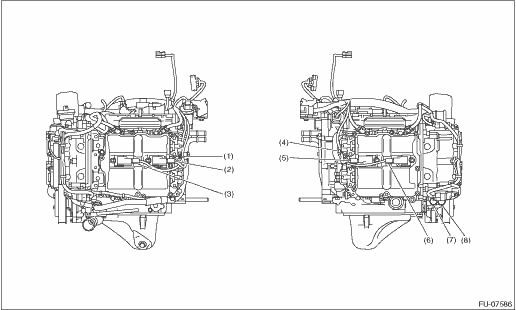

• Structural diagram 2

(1) | Secure the clip to the screw hole. | |

(2) | Ignition coil No. 4 | |

(3) | Ignition coil No. 2 | |

(4) | Secure the clip to the screw hole. | |

(5) | Ignition coil No. 3 | |

(6) | Ignition coil No. 1 | |

(7) | Front oxygen (A/F) sensor | |

(8) | Rear oxygen sensor | |

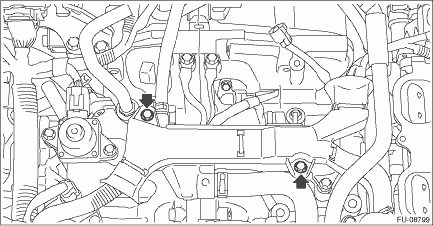

2. Install the engine wiring harness.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

3. Install the intake manifold. Intake Manifold > INSTALLATION">

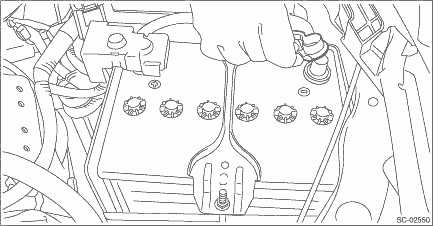

4. Connect the battery ground terminal.

Removal

Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Engine Wiring HarnessREMOVAL1. Release the fuel pressure. Fuel > PROCEDURE">2. Disconnect the ground cable from battery.3. Remove the intake manifo ...

Other materials:

Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Throttle BodyINSPECTION1. THROTTLE SENSOR (METHOD WITH CIRCUIT TESTER)1. Remove the glove box. Glove Box > REMOVAL">2. Turn the ignition switch to ON. (engine OFF)3. Measure the voltage between ECM connector terminals.(A)To ECM connector Thrott ...

Weight

SPECIFICATIONS > CrosstrekWEIGHTModel5 door2.0 L DOHC non-turbo2.0 i5MTCVTOP codeU5C5U5C53A3A3A3ACurb weight (C.W.)Totalkg(lb)1,410(3,109)1,410(3,109)1,445(3,186)1,445(3,186)Frontkg(lb)825(1,819)825(1,819)865(1,907)865(1,907)Rearkg(lb)585(1,290)585(1,290)580(1,279)580(1,279)Gross vehicle weight ( ...

Caution

HVAC SYSTEM (HEATER, VENTILATOR AND A/C) > General DescriptionCAUTION• Before disassembling or reassembling parts, always disconnect the battery ground cable from battery. When replacing the radio, control module, and other parts provided with memory functions, record the memory contents be ...