Subaru Crosstrek Service Manual: Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Engine Wiring Harness

REMOVAL

1. Release the fuel pressure. Fuel > PROCEDURE">

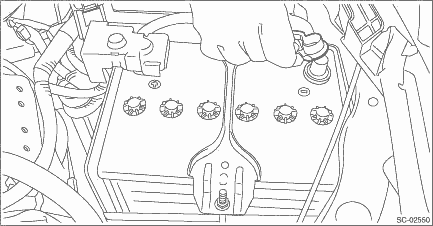

2. Disconnect the ground cable from battery.

3. Remove the intake manifold. Intake Manifold > REMOVAL">

4. Disconnect the connector from the engine.

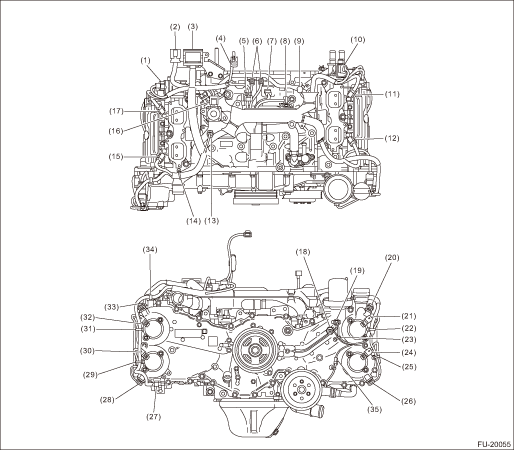

• Structural diagram 1

(1) | Tumble generator valve actuator RH | |

(2) | Engine harness connector (16P) | |

(3) | Engine harness connector (54P) | |

(4) | Throttle position sensor connector | |

(5) | Manifold absolute pressure sensor connector | |

(6) | Engine ground (2 locations) | |

(7) | Crankshaft position sensor | |

(8) | Knock sensor | |

(9) | Purge control solenoid valve connector | |

(10) | Tumble generator valve actuator LH | |

(11) | Fuel injector (#4) | |

(12) | Fuel injector (#2) | |

(13) | Engine coolant temperature sensor | |

(14) | Remove the clip from the screw hole. | |

(15) | Fuel injector (#1) | |

(16) | EGR valve | |

(17) | Fuel injector (#3) | |

(18) | Oil pressure switch | |

(19) | Engine oil temperature sensor | |

(20) | Intake camshaft position sensor LH | |

(21) | Intake oil control solenoid LH | |

(22) | Remove the clip from the screw hole. | |

(23) | Remove the clip from the screw hole. | |

(24) | Exhaust oil control solenoid LH | |

(25) | Remove the clip from the screw hole. | |

(26) | Exhaust camshaft position sensor LH | |

(27) | Remove the clip from the oval hole. | |

(28) | Exhaust camshaft position sensor RH | |

(29) | Remove the clip from the screw hole. | |

(30) | Exhaust oil control solenoid RH | |

(31) | Remove the clip from the screw hole. | |

(32) | Intake oil control solenoid RH | |

(33) | Intake camshaft position sensor RH | |

(34) | Remove the clip from the screw hole. | |

(35) | Oil level switch connector | |

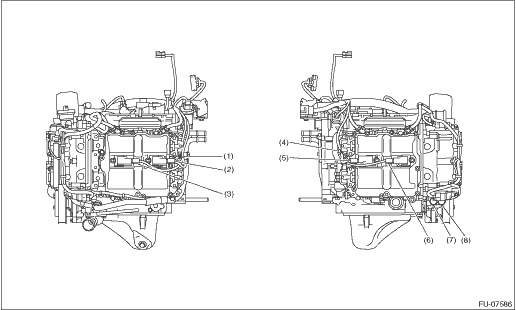

• Structural diagram 2

(1) | Remove the clip from the screw hole. | |

(2) | Ignition coil No. 4 | |

(3) | Ignition coil No. 2 | |

(4) | Remove the clip from the screw hole. | |

(5) | Ignition coil No. 3 | |

(6) | Ignition coil No. 1 | |

(7) | Front oxygen (A/F) sensor | |

(8) | Rear oxygen sensor | |

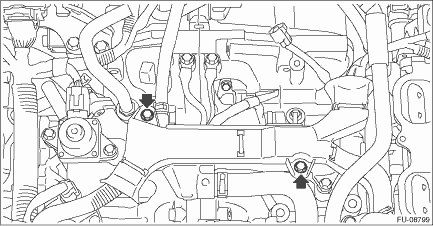

5. Remove the engine wiring harness.

Inspection

Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Engine Wiring HarnessINSPECTIONCheck that the engine wiring harness does not have deformation, cracks and any other damage. ...

Installation

Installation

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Engine Wiring HarnessINSTALLATION1. Route the engine wiring harness around the engine and connect connectors.• Structural diagram 1(1)Tumble generator va ...

Other materials:

Removal

LIGHTING SYSTEM > Back-up Light BulbREMOVAL1. CROSSTREK MODEL1. Disconnect the ground cable from battery. NOTE">2. Remove the light assembly - rear combination.CAUTION:Be careful not to damage the clips.(1) Release the bolts and clips, then pull out the light assembly - rear combination ...

Select lever/gear position indicator (CVT models)

Type A

Upshift indicator

Downshift indicator

Select lever/gear position indicator

Type B

Upshift indicator

Downshift indicator

Select lever/gear position indicator

This indicator shows the position of the

select lever.

When the manual mode is selected, the

gear pos ...

Removal

LIGHTING SYSTEM > Headlight AssemblyREMOVALCAUTION:• Do not perform work with wet hands, because there is a possibility of electrical shock.• The HID type uses very high voltages for the lighting circuit. Make sure that the power supply is turned OFF before working.1. Disconnect the g ...