Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Rear Axle

INSTALLATION

1. Temporarily tighten the rear axle housing to the upper arm assembly.

2. Install the rear drive shaft assembly.

CAUTION:

• Do not hammer the drive shaft assembly when installing.

• Use new axle nuts.

(1) Insert the drive shaft assembly into the hub spline, and pull it into the specified position.

(2) Tighten the axle nut temporarily.

3. Tighten the rear strut assembly, rear stabilizer link and other links to the specified torque.

Tightening torque:

Rear suspension: General Description > COMPONENT">

Rear strut: General Description > COMPONENT">

4. Install the rear disc rotor.

5. Install the caliper body assembly.

Tightening torque:

Refer to “COMPONENT” of “General Description” for the tightening torque. General Description > COMPONENT">

6. Install the brake hose bracket and rear ABS wheel speed sensor.

Tightening torque:

Brake hose bracket: 33 N·m (3.4 kgf-m, 24.3 ft-lb)

Rear ABS wheel speed sensor: 7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

7. Install the sensor assembly - headlight beam leveler. (Model with auto headlight beam leveler)

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

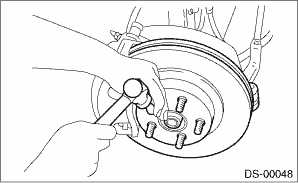

8. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the rear axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

190 N·m (19.4 kgf-m, 140.1 ft-lb)

9. After tightening the axle nut, lock it securely.

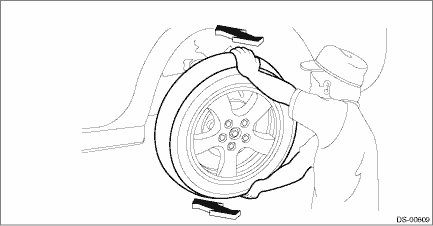

10. Install the rear wheels, and perform the following inspections.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

(1) Check the wheels for smooth rotation.

(2) Check that there is no looseness by moving the upper and lower portions of rear tire in an axial direction with the brake pedal released.

• Looseness exists > Check the rear hub unit bearing. Rear Hub Unit Bearing > INSPECTION">

11. Inspect the wheel alignment and adjust if necessary.

• Inspection: Wheel Alignment > INSPECTION">

• Adjustment: Wheel Alignment > ADJUSTMENT">

12. Perform reinitialization of the auto headlight beam leveler system. (Model with auto headlight beam leveler) Auto Headlight Beam Leveler System > PROCEDURE">

Disassembly

Disassembly

DRIVE SHAFT SYSTEM > Rear AxleDISASSEMBLY1. BUSHING - REAR AXLE HOUSINGDo not remove the bushing - rear axle housing from the rear axle housing, because it cannot be replaced. If removed, replace t ...

Rear drive shaft

Rear drive shaft

...

Other materials:

Wiring diagram

SECURITY AND LOCKS > Push Button Start SystemWIRING DIAGRAMFor wiring diagrams related to the push button start system (ignition change), refer to the following items.• Keyless access system: Keyless Access System > WIRING DIAGRAM">• Push button start system: Push Button ...

Engine oil

CAUTION

If the level gauge cannot be

pulled out easily, twist the level

gauge right and left, then gently

pull it out. Otherwise, you may be

injured accidentally straining

yourself.

Use only engine oil with the

recommended grade and viscosity.

Be careful not to spill engine oil

...

Caution

COOLING(H4DO) > General DescriptionCAUTION• Prior to starting work, pay special attention to the following:1. Always wear work clothes, a work cap, and protective shoes. Additionally, wear a helmet, protective goggles, etc. if necessary.2. Protect the vehicle using a seat cover, fender cove ...