Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Propeller Shaft

INSTALLATION

1. Before installation, check the following items, and replace the propeller shaft assembly as necessary.

• Dents or cracks on the tube surface

• Splines for deformation or abnormal wear

• Unsmooth joint operation or abnormal noise

• Center bearing for free play, noise or non-smooth operation.

• Oil seals for abnormal wear or damage

• Damaged center bearing

2. Apply fluid or gear oil to the oil seal lip and the propeller shaft.

• CVT model: SUBARU CVT OIL FOR LINEARTRONIC

• MT model: GL-5

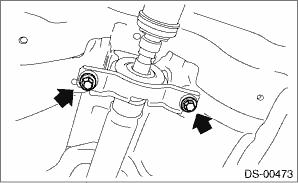

3. Insert the sleeve yoke into the transmission and attach center bearing to body.

Tightening torque:

52 N·m (5.3 kgf-m, 38.4 ft-lb)

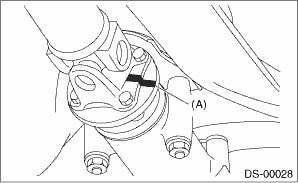

4. Align the alignment marks (A), and connect the yoke flange and rear differential.

Tightening torque:

31 N·m (3.2 kgf-m, 22.9 ft-lb)

5. Check the propeller shaft with the propeller shaft installed to the vehicle. Propeller Shaft > INSPECTION">

6. Install the center exhaust cover.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

7. Install the center exhaust pipe, rear exhaust pipe and muffler.

• Center exhaust pipe & rear exhaust pipe: Rear Exhaust Pipe > INSTALLATION">

• Muffler: Muffler > INSTALLATION">

8. Install the under cover - front.

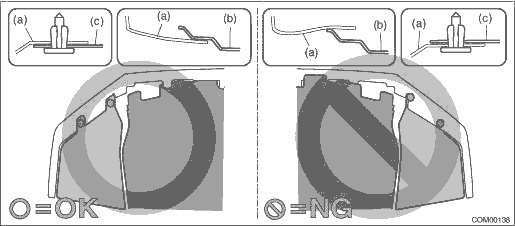

CAUTION:

Install so that the front end of the under cover (b) comes inside the bumper face - front (a), and the front end of the mud guard (c) comes outside the bumper face - front (a).

Tightening torque:

18 N·m (1.84 kgf-m, 13.3 ft-lb)

9. Lower the vehicle.

Removal

Removal

DRIVE SHAFT SYSTEM > Propeller ShaftREMOVALCAUTION:• Before removing propeller shaft, wrap metal parts with a cloth or rubber material.• Do not disassemble the center EDJ of the propell ...

Rear axle

Rear axle

...

Other materials:

Dtc p1160 throttle return spring

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P1160 THROTTLE RETURN SPRINGNOTE:For the diagnostic procedure, refer to DTC P2101. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2101 THROTTLE ACTUATOR "A" CONTROL MOTOR CIRCUIT ...

Dtc b1833 short in curtain shield airbag rh squib circuit (to +b)

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B1833 SHORT IN CURTAIN SHIELD AIRBAG RH SQUIB CIRCUIT (TO +B)Diagnosis start condition:Ignition voltage is 10 V to 16 V.DTC detecting condition:• Curtain airbag harness (RH) is shorted to power supply.• Curtain airbag ...

Specification

WIPER AND WASHER SYSTEMS > General DescriptionSPECIFICATIONFront wiper motorInput12 V — 72 W or lessRear wiper motorInput12 V — 42 W or lessFront washer motorPump typeCentrifugalInput12 V — 60 W or lessRear washer motorPump typeCentrifugalInput12 V — 36 W or less ...