Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Front Hub Unit Bearing

INSTALLATION

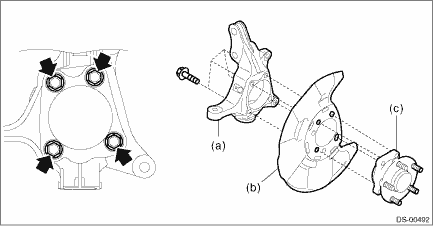

1. Place the front brake back plate between the front axle housing and the front hub unit bearing, and tighten the bolt.

CAUTION:

• Do not get closer the tool which charged magnetism to magnetic encoder.

• Be careful not to damage the magnetic encoder.

• Use a new bolt.

Tightening torque:

65 N·m (6.6 kgf-m, 47.9 ft-lb)

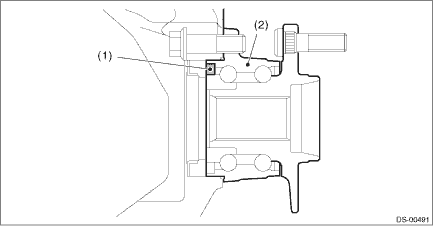

(1) | Magnetic encoder | (2) | Front hub unit bearing |

(a) | Front axle housing | (b) | Front brake back plate | (c) | Front hub unit bearing |

Tightening torque:

65 N·m (6.6 kgf-m, 47.9 ft-lb)

2. Install the front drive shaft assembly.

CAUTION:

• Do not hammer the drive shaft assembly when installing.

• Use new axle nuts.

(1) Insert the drive shaft assembly into the hub spline, and pull it into the specified position.

(2) Tighten the axle nut temporarily.

3. Install the disc rotor to the front hub unit bearing.

4. Install the caliper body assembly to the front axle housing.

Tightening torque:

Refer to “COMPONENT” of “General Description” for the tightening torque. General Description > COMPONENT">

5. Install the brake hose bracket.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

6. Install the front ABS wheel speed sensor.

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

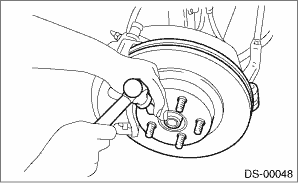

7. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the front axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

220 N·m (22.4 kgf-m, 162.3 ft-lb)

8. After tightening the axle nut, lock it securely.

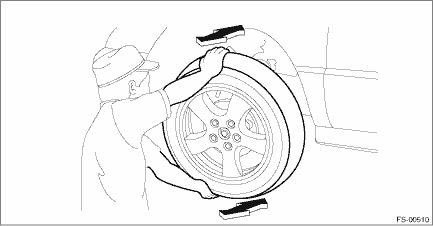

9. Install the front wheels, and perform the following inspections.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

(1) Check the wheels for smooth rotation.

(2) Check that there is no looseness by moving the upper and lower portions of front tire in an axial direction with the brake pedal released.

• Looseness exists > Check the front hub unit bearing. Front Hub Unit Bearing > INSPECTION">

(3) Check that there is no looseness by moving the upper and lower portions of front tire in an axial direction with the brake pedal depressed.

• Looseness exists > Replace the ball joint assembly. Front Ball Joint > REMOVAL">

Inspection

Inspection

DRIVE SHAFT SYSTEM > Front Hub Unit BearingINSPECTION1. Moving the front tire up and down by hand, check there is no looseness in bearing, and check the wheel rotates smoothly.CAUTION:If there is u ...

Other materials:

Sliding moonroof

Open

Close

To open:

Press and hold the rear side of the

"OPEN/CLOSE" switch. The sun shade

will also be opened together with the

moonroof. The moonroof will stop at a

position approximately 1.6 in (4 cm) away

from the fully opened position. Press and

hold the rear side of the swit ...

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Parking PawlREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Shift the range select lever to “N” range.3. Remove the extension case. Extension Case > REMOVAL"> ...

Removal

AIRBAG SYSTEM > Driver’s Airbag ModuleREMOVALCAUTION:Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">1. Position the front wheels straight ahead.2. Tu ...