Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Front Drive Shaft

INSTALLATION

1. Before installation, check the drive shaft assembly. Front Drive Shaft > INSPECTION">

2. Replace the differential side retainer oil seal with a new part.

• MT model: Differential Side Retainer Oil Seal > REPLACEMENT">

• CVT model: Differential Side Retainer Oil Seal > REPLACEMENT">

NOTE:

After pulling out the drive shaft assembly, be sure to replace with a new oil seal.

3. Insert the drive shaft assembly into the hub spline, and pull it into the specified position.

CAUTION:

Do not hammer the drive shaft assembly when installing.

4. Tighten the axle nut temporarily.

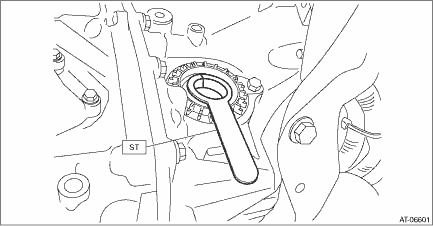

5. Using the ST, install the front drive shaft assembly to the transmission.

Preparation tool:

ST: OIL SEAL PROTECTOR (28399SA010)

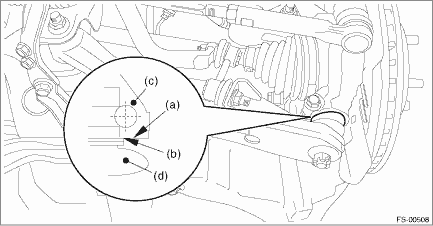

6. Install the ball joint assembly to the front axle housing.

CAUTION:

Before tightening, make sure the lower side of front axle housing and stepped section of ball joint are in contact.

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

(a) | Lower side of front axle housing | (c) | Front axle housing | (d) | Ball joint |

(b) | Raised section of ball joint |

7. Install the stabilizer link.

Tightening torque:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

8. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the front axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

220 N·m (22.4 kgf-m, 162.3 ft-lb)

9. After tightening axle nut, lock it securely.

10. Fill transmission gear oil. (MT model)

11. Fill differential gear oil. (CVT model)

12. Install the front wheels.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

13. Inspect the wheel alignment and adjust if necessary.

• Inspection: Wheel Alignment > INSPECTION">

• Adjustment: Wheel Alignment > ADJUSTMENT">

CAUTION:

When the wheel alignment has been adjusted, perform “VDC sensor midpoint setting mode”. VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT"> VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT">

VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT"> VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT">

VDC Control Module and Hydraulic Control Unit (VDCCM&H/U) > ADJUSTMENT">

14. Perform reinitialization of the auto headlight beam leveler system. (Model with auto headlight beam leveler) Auto Headlight Beam Leveler System > PROCEDURE">

Inspection

Inspection

DRIVE SHAFT SYSTEM > Front Drive ShaftINSPECTIONCheck the removed parts for damage, wear, corrosion etc. If faulty, repair or replace.• PTJ (pillow tripod joint)Check for seizure, corrosion, ...

Other materials:

Installation

ENTERTAINMENT > Switches and HarnessINSTALLATION1. SATELLITE SWITCH ASSEMBLYCAUTION:• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">• Do not a ...

Component

LUBRICATION(H4DO) > General DescriptionCOMPONENT1. OIL PAN AND STRAINER(1)Oil pan upper(8)Drain plug gasketTightening torque: N·m (kgf-m, ft-lb)(2)O-ring(9)Drain plugT1:5 (0.5, 3.7)(3)Baffle plate(10)Oil level switchT2:6.4 (0.7, 4.7)(4)O-ring(11)O-ringT3:10 (1.0, 7.4)(5)Oil strainer(12)Plu ...

Data link connector Note

ENGINE (DIAGNOSTICS)(H4DO) > Data Link ConnectorNOTEThis connector is used for Subaru Select Monitor.CAUTION:Do not connect any scan tools other than Subaru Select Monitor or general scan tool because the circuit may be damaged.Terminal No.ContentsTerminal No.Contents1Blank9Blank2Blank10Blank3Bla ...