Subaru Crosstrek Service Manual: Installation

CLUTCH SYSTEM > Release Bearing and Lever

INSTALLATION

NOTE:

Apply the specified grease to lubricate to the following points before installation.

• Contact surface of lever and pivot

• Contact surface of lever and bearing

• Transmission main shaft spline

• Contact surface of release bearing and transmission case

Grease

NICHIMOLY N-130 or equivalent

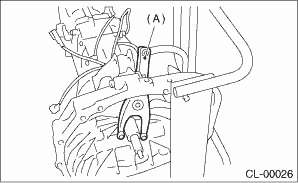

1. While pushing the release lever to the pivot and twisting it to both sides, fit the lever spring onto the raised portion of the pivot.

NOTE:

Observing from the main case hole, check that the lever spring is installed securely.

(A) | Release lever |

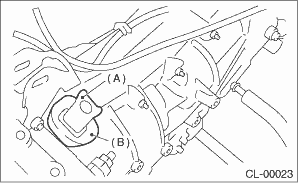

2. Install the release bearing and fasten it with two clips.

3. Install the dust cover.

(A) | Release lever |

(B) | Dust cover |

4. Operate the release lever and check if the release bearing moves smoothly.

5. Apply grease to the contact point of the release lever and operating cylinder.

Grease

NICHIMOLY N-130 or equivalent

6. Install the transmission assembly. Manual Transmission Assembly > INSTALLATION">

Removal

Removal

CLUTCH SYSTEM > Release Bearing and LeverREMOVAL1. Remove the transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the two clips from the release lev ...

Clutch fluid air bleeding Procedure

Clutch fluid air bleeding Procedure

CLUTCH SYSTEM > Clutch Fluid Air BleedingPROCEDURECAUTION:Be careful not to spill the brake fluid. Brake fluid spilled on the vehicle body will harm the paint surface; wash it off with water and wi ...

Other materials:

Dtc b14e1 air mix door actuator stepping motor circuit open (driver)

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B14E1 AIR MIX DOOR ACTUATOR STEPPING MOTOR CIRCUIT OPEN (DRIVER)DTC detecting condition:Air mix door actuator stepping motor circuit is open.Trouble symptom:Temperature cannot be adjusted.Wiring diag ...

Dtc u0073 control module communication bus off

Blind Spot Detection/Rear Cross Traffic Alert (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0073 CONTROL MODULE COMMUNICATION BUS OFFDetected when CAN line abnormality is detected.NOTE:Perform the diagnosis for LAN system. Basic Diagnostic Procedure > PROCEDURE&q ...

Dtc p0103 mass or volume air flow sensor "a" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0103 MASS OR VOLUME AIR FLOW SENSOR "A" CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Improper idling• Engine stall• Poor driving performanc ...