Subaru Crosstrek Service Manual: Inspection

WIPER AND WASHER SYSTEMS > Washer Tank and Motor

INSPECTION

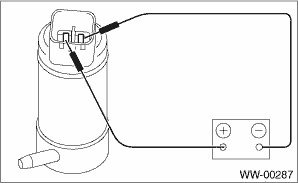

1. WASHER PUMP

Apply battery voltage to the connector terminal of the motor pump assembly - washer, and make sure that the motor operates.

2. WASHER FLUID LEVEL SENSOR

1. Check the connection status of washer fluid level sensor connector.

2. Does the low washer fluid warning light illuminate after draining the washer fluid? And does the low washer fluid warning light go off after refilling the washer fluid?

• Yes > Normal operation.

• No > Perform step 3.

3. Using a tester, measure the voltage of the washer fluid level sensor connector.

(1) Is the voltage approx. 8.5 V or more?

• Yes > Perform step 4.

• No > Check harness, meter and integrated unit, and replace if necessary.

4. Does the meter indicator illuminate if you short the washer fluid level sensor connector?

• Yes > Perform step 5.

• No > Check meter and integrated unit, and replace if necessary.

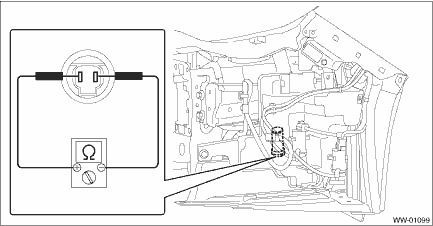

5. Using a tester, measure the resistance of the washer fluid level sensor.

(1) Turn over the mud guard.

(2) Measure the resistance of the washer fluid level sensor.

Amount of washer fluid in the tank | Standard |

No remaining quantity (ON) | Less than 10 ? |

There is remaining quantity (OFF) | 1 M? or more |

(3) Is the resistance within the standard?

• Yes > Normal operation.

• No > Replace the washer fluid level sensor along with the washer tank.

Removal

Removal

WIPER AND WASHER SYSTEMS > Washer Tank and MotorREMOVAL1. WASHER TANK1. Open the hood COMPL - front.2. Disconnect the ground cable from battery. NOTE">3. Remove the bumper face - front. F ...

Other materials:

Inspection

LIGHTING SYSTEM > Door SwitchINSPECTION1. Check the resistance between switch terminals.Preparation tool:Circuit testerTerminal No.Inspection conditionsStandardConnection diagram1 — 3When door is openedLess than 1 ?When door is closed1 M? or more2. Replace the switch assembly - door if the insp ...

Specification

IGNITION(H4DO) > General DescriptionSPECIFICATIONItemSpecificationsIgnition coilManufacturer and typeHitachi: EIC-2230Ignition systemIndependent ignition coilSpark plugManufacturer and typeNGK: SILZKAR7B11Thread size (diameter, pitch, length)mm12, 1.25, 26.5Spark plug gapmm (in)Standard1.0 — 1. ...

Inspection

INSTRUMENTATION/DRIVER INFO > Multi-function Display (MFD)INSPECTION1. MULTI-FUNCTION DISPLAY SWITCH1. Measure the resistance between connector terminals.Preparation tool:Circuit testerTerminal No.Inspection conditionsStandard2 — 3 (UP)ENTER (DOWN)All OFF1 M? or more (UP)ONLess than 1 ?ENTERONA ...