Subaru Crosstrek Service Manual: Inspection

POWER ASSISTED SYSTEM (POWER STEERING) > Electric Power Steering Gearbox

INSPECTION

1. UNIT INSPECTION

Check components for wear, damage or other faults. Adjust or replace if necessary.

2. LIMIT

Make a measurements as follows. If it exceeds the specified service limits, adjust or replace.

NOTE:

When fixing the steering gearbox assembly in a vise, apply a wooden piece on the flange portion.

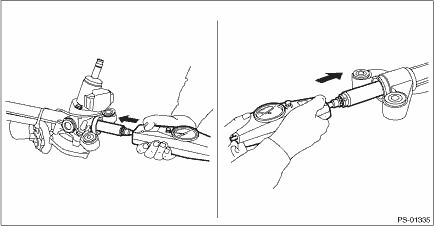

Rack shaft sliding resistance:

Limit: 303 N (31 kgf, 68 lbf) or less

Left/right differential of sliding resistance: 20% or less

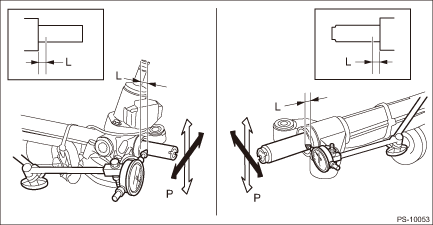

3. RACK SHAFT PLAY IN THE RADIAL DIRECTION

NOTE:

• When fixing the steering gearbox assembly in a vise, apply a wooden piece on the flange portion.

• When fixing the magnet stand in the steering gearbox assembly, perform the following procedure.

– Fix the iron plate on the flange portion using a c-clamp, and place the magnet stand on the iron plate.

– Use bolts and nuts to fix directly on the flange portion of the steering gearbox assembly. (Secure the gauge firmly on the gearbox body. (Avoid the input shaft and the rack shaft.))

Right-turn steering:

Service limit:

Both amplitudes: 0.6 mm (0.024 in) or less

Left-turn steering:

Service limit:

Both amplitudes: 0.6 mm (0.024 in) or less

Condition:

L: 5 mm (0.2 in) from dust cover

Rack shaft end P: 98 N (10 kgf, 22 lbf)

NOTE:

The location where the magnet stand is installed varies to stabilize the magnet stand.

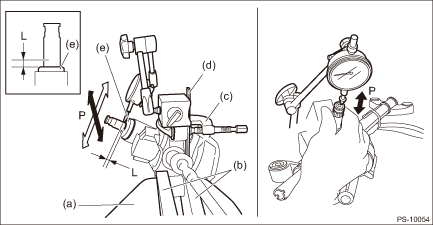

4. INPUT SHAFT PLAY

NOTE:

• When fixing the steering gearbox assembly in a vise, apply a wooden piece on the flange portion.

• When fixing the magnet stand in the steering gearbox assembly, perform the following procedure.

– Fix the iron plate on the flange portion using a c-clamp, and place the magnet stand on the iron plate.

– Use bolts and nuts to fix directly on the flange portion of the steering gearbox assembly. (Secure the gauge firmly on the gearbox body. (Avoid the input shaft and the rack shaft.))

In radial direction:

Limit: Both amplitudes: 0.6 mm (0.024 in) or less

Condition: Input shaft tip P = 98 N (10 kgf, 22 lbf)

In axial direction:

Limit: 0.27 mm (0.0106 in) or less

Condition: Input shaft tip P = 20 — 49 N (2 — 5 kgf, 4 — 11 lbf)

NOTE:

The location where the magnet stand is installed varies to stabilize the magnet stand.

(a) | Vise | (c) | C-clamp | (e) | Dust cover |

(b) | Wooden block | (d) | Iron plate |

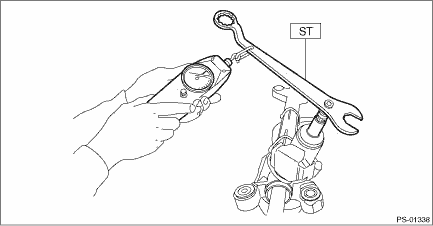

5. TURNING RESISTANCE OF GEARBOX

1. Using the ST, measure the rotational resistance of the steering gearbox assembly.

Preparation tool:

ST: SPANNER (34099PA100)

Service limit:

Maximum allowable resistance: 18.0 N (1.8 kgf, 4.0 lbf) or less

Difference between right and left rotational resistance: 20% or less

Disassembly

Disassembly

POWER ASSISTED SYSTEM (POWER STEERING) > Electric Power Steering GearboxDISASSEMBLYCAUTION:• Nut for fixing the rack is on the driver’s side only. When removing the tie-rod on the passe ...

Installation

Installation

POWER ASSISTED SYSTEM (POWER STEERING) > Electric Power Steering GearboxINSTALLATION1. Insert the steering gearbox assembly into crossmember, being careful not to damage the boot of the steering ge ...

Other materials:

Component

COMMUNICATION SYSTEM > General DescriptionCOMPONENT(1)Horn switch (driver’s airbag module ASSY)(3)Horn relay(5)Horn ASSY - Hi(2)Roll connector(4)Horn ASSY - Lo ...

Removal

EXTERIOR/INTERIOR TRIM > Instrument Panel AssemblyREMOVALCAUTION:• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">• Be careful not to damage th ...

Installation

EXTERIOR BODY PANELS > Front HoodINSTALLATIONCAUTION:The hood COMPL - front is heavy. When removing or installing the hinge COMPL - front hood, be sure to work in a group of two or more.1. To install the insulator - front hood and the seal - front duct, follow the removal procedure in the reverse ...