Subaru Crosstrek Service Manual: Inspection

GLASS/WINDOWS/MIRRORS > Power Window Control Switch

INSPECTION

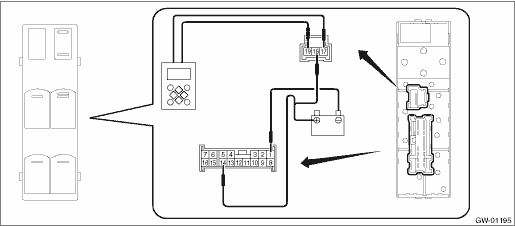

1. MAIN SWITCH

• Driver’s seat

CAUTION:

Since the switch - power window main is controlled by CPU, do not check continuity for switch alone with the circuit tester. Performing continuity check with circuit tester can damage the switch - power window main circuit.

Check output from the switch - power window main to the driver’s side motor using the oscilloscope function in the Subaru Select Monitor.

1. Remove the switch - power window main.

2. Connect the battery and the Subaru Select Monitor to the switch - power window main terminal.

CAUTION:

Never mix up the terminals when connecting the harness connector of the switch - power window main and the battery. If the connection is wrong, the switch - power window main may be damaged.

NOTE:

• When the battery is connected to the switch - power window main terminal, the letters “AUTO” on the driver’s side knob illuminates.

• For detailed procedures, refer to “Subaru Select Monitor Operation Manual”.

3. Operate the switch - power window main and check the output.

NOTE:

Since output time during window UP operation is extremely short, it cannot be checked without using a measuring instrument such as oscilloscope. Output is constantly produced while the switch is operated for window DOWN operation.

Inspection conditions | Output time | Standard |

AUTO UP | Approx. 130 ms | Battery voltage |

UP | ||

OFF | — | 0 V |

DOWN | During switch operation | Battery voltage |

AUTO DOWN | Approx. 300 ms |

4. If the inspection result is not within the standard, replace the switch - power window main.

• Except for driver’s seat

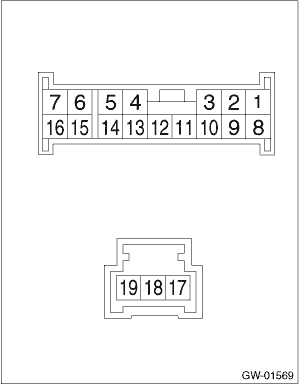

1. Check the resistance between terminals of the switch - power window main.

Terminal No. | Inspection conditions | Standard | |

Passenger’s seat | 14 — 8 1 — 2 | UP | Less than 1 ? |

14 — 2 14 — 8 | OFF | 1 M? or more | |

1 — 8 1 — 2 8 — 2 | Less than 1 ? | ||

14 — 2 1 — 8 | DOWN | Less than 1 ? | |

Rear LH | 14 — 15 1 — 16 | UP | Less than 1 ? |

14 — 15 14 — 16 | OFF | 1 M? or more | |

1 — 15 1 — 16 15 — 16 | Less than 1 ? | ||

14 — 16 1 — 15 | DOWN | Less than 1 ? | |

Rear RH | 14 — 7 1 — 6 | UP | Less than 1 ? |

14 — 7 14 — 6 | OFF | 1 M? or more | |

1 — 6 1 — 7 6 — 7 | Less than 1 ? | ||

14 — 6 1 — 7 | DOWN | Less than 1 ? |

2. If the inspection result is not within the standard, replace the switch - power window main.

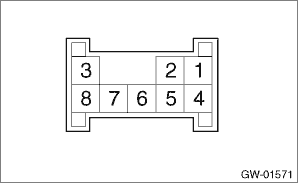

2. SUB-SWITCH

1. Remove the switch - power window sub.

2. Check the resistance between terminals of the switch - power window sub.

Terminal No. | Inspection conditions | Standard | |

Passenger seat, rear | 6 — 5 8 — 7 | UP | Less than 1 ? |

7 — 6 4 — 6 | OFF | 1 M? or more | |

5 — 4 8 — 7 | Less than 1 ? | ||

6 — 8 5 — 4 | DOWN | Less than 1 ? |

3. If the inspection result is not within the standard, replace the switch - power window sub.

Removal

Removal

GLASS/WINDOWS/MIRRORS > Power Window Control SwitchREMOVAL1. MAIN SWITCH1. Disconnect the ground cable from battery and wait for at least 60 seconds before starting work. NOTE">2. Remove t ...

Other materials:

Removal

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > EGR PipeREMOVAL1. Disconnect the ground cable from battery.2. Remove the clip (A), and loosen the clamps (B) and (C) securing the air intake boot.3. Remove the air intake boot from the air cleaner case (rear) and throttle body, and move the ...

Dtc b1571 reference code incompatibility (immobilizer cm to ecm)

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B1571 REFERENCE CODE INCOMPATIBILITY (IMMOBILIZER CM TO ECM)DTC detecting condition:Incompatibility of reference code between keyless access CM (model without ID code box) or ID ...

Specification

VEHICLE DYNAMICS CONTROL (VDC) > VDC Sequence ControlSPECIFICATION1. CONDITIONS FOR COMPLETION OF VDC SEQUENCE CONTROLWhen the following conditions develop, the VDC sequence control stops and VDC operation is returned to the normal control mode.• When the speed of at least one wheel reaches ...