Subaru Crosstrek Service Manual: Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Tumble Generator Valve Assembly

INSPECTION

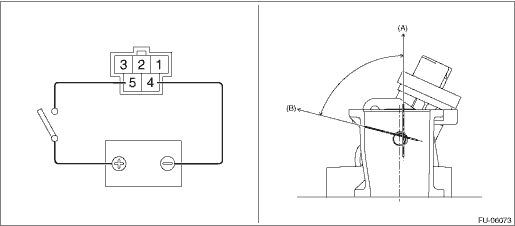

1. CHECK MOTOR

1. Connect the battery positive terminal to terminal No. 5 and the battery ground terminal to terminal No. 4, and check that the valve is fully opened on LH side and the valve is fully closed on RH side.

CAUTION:

Do not power the motor for more than 10 seconds.

(A) | Full open | (B) | Full closed |

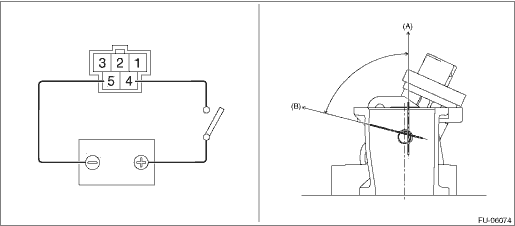

2. Connect the battery positive terminal to terminal No. 4 and the battery ground terminal to terminal No. 5, and check that the valve is fully closed on LH side and the valve is fully opened on RH side.

CAUTION:

Do not power the motor for more than 10 seconds.

(A) | Full open | (B) | Full closed |

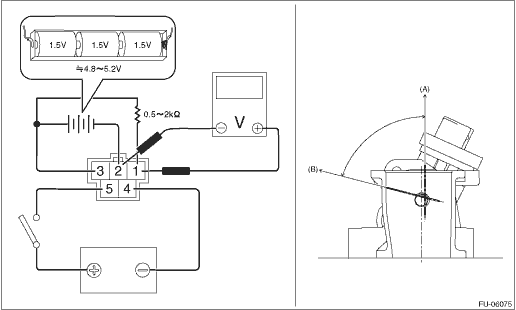

2. CHECK SENSORS

1. Connect dry-cell battery positive terminal to terminal No. 3 and dry-cell battery ground terminal to terminal No. 2, and connect the resistance (0.5 — 2 k?) between dry-cell battery positive terminal and terminal No. 1.

NOTE:

• Use new dry-cell batteries.

• Using circuit tester, check the voltage of a single dry-cell battery is 1.6 V or more. And also check the voltage of three batteries in series is between 4.8 V and 5.2 V.

• For power supply, 5 V DC voltage source can also be used.

2. Connect the circuit tester positive terminal to terminal No. 1, and the circuit tester negative terminal to terminal No. 2.

3. Connect the battery positive terminal to terminal No. 5 and the battery ground terminal to terminal No. 4, and measure the voltages with the valve fully opened on LH side and with the valve fully closed on RH side.

CAUTION:

Do not power the motor for more than 10 seconds.

(A) | Full open | (B) | Full closed |

Terminal No. | Standard |

1 (+) and 2 (−) | LH side: Approx. 5 V (when 25°C (77°F)) RH side: Approx. 0 — 0.5 V (when 25°C (77°F)) |

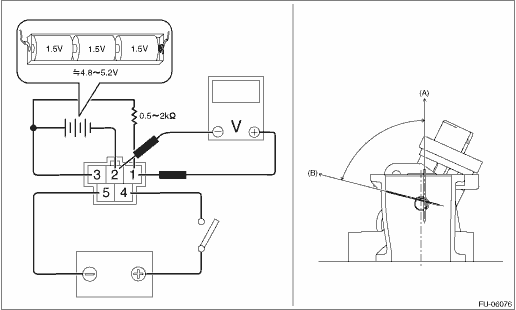

4. Connect dry-cell battery positive terminal to terminal No. 3 and dry-cell battery ground terminal to terminal No. 2, and connect the resistance (0.5 — 2 k?) between dry-cell battery positive terminal and terminal No. 1.

NOTE:

• Use new dry-cell batteries.

• Using circuit tester, check the voltage of a single dry-cell battery is 1.6 V or more. And also check the voltage of three batteries in series is between 4.8 V and 5.2 V.

• For power supply, 5 V DC voltage source can also be used.

5. Connect the circuit tester positive terminal to terminal No. 1, and the circuit tester negative terminal to terminal No. 2.

6. Connect the battery positive terminal to terminal No. 4 and the battery ground terminal to terminal No. 5, and measure the voltages with the valve fully closed on LH side and with the valve fully opened on RH side.

CAUTION:

Do not power the motor for more than 10 seconds.

(A) | Full open | (B) | Full closed |

Terminal No. | Standard |

1 (+) and 2 (−) | LH side: Approx. 0 — 0.5 V (when 25°C (77°F)) RH side: Approx. 5 V (when 25°C (77°F)) |

3. OTHER INSPECTIONS

1. Check that the tumble generator valve assembly has no deformation, cracks or other damages.

2. Check tumble generator valve assembly for contamination or clogging.

Removal

Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Tumble Generator Valve AssemblyREMOVAL1. Release the fuel pressure. Fuel > PROCEDURE">2. Disconnect the ground cable from battery.3. Remove the int ...

Other materials:

Inspection

CLUTCH SYSTEM > Master CylinderINSPECTIONIf any damage, deformation, wear, swelling, rust or other faults are found on the cylinder, piston, push rod, nipple, return spring, bleeder screw, seat or hose, replace the faulty part.(A)Master cylinder body(B)Seat(C)Return spring(D)Piston(E)Piston stop ...

System features

BSD/RCTA consists of the following functions.

To detect a vehicle in a blind spot on an

adjacent lane or a vehicle approaching at

high speed while driving the vehicle (Blind

Spot Detection)

To detect a vehicle approaching from

the right or left while reversing the vehicle

(Rear Cross ...

Removal

HVAC SYSTEM (HEATER, VENTILATOR AND A/C) > CondenserREMOVAL1. Using the refrigerant recovery system, discharge refrigerant. Refrigerant Recovery Procedure > PROCEDURE">2. Remove the air intake duct. Air Intake Duct > REMOVAL">3. Remove the clip, and remove the bracket - gr ...