Subaru Crosstrek Service Manual: Inspection

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve Assembly

INSPECTION

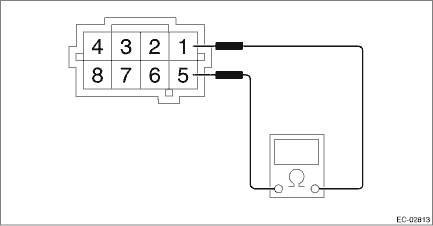

1. CHECK SWITCHING VALVE

1. Check the resistance between switching valve terminals.

Terminal No. | Standard |

1 and 5 | 27+3 −2 ? (when 20°C (68°F)) |

31±4 ? (60°C (140°F)) |

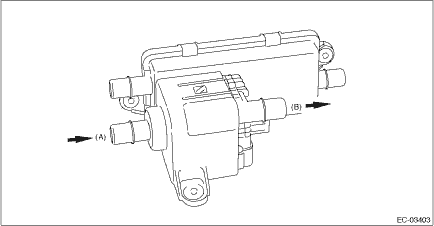

2. Check that air is discharged from (B) when air is blown into (A).

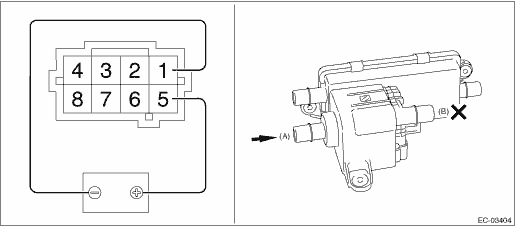

3. Connect the battery positive terminal to the terminal No. 5 and the battery negative terminal to the terminal No. 1. Check that air does not come out from (B) when air is blown into (A).

NOTE:

The purpose of this inspection is to check the valve movement, and it would be success if a large change of flow can be checked resulting from valve opening/closing. Therefore, it does not indicate a malfunction if a small amount of flow from (B) is detected when the valve is opened.

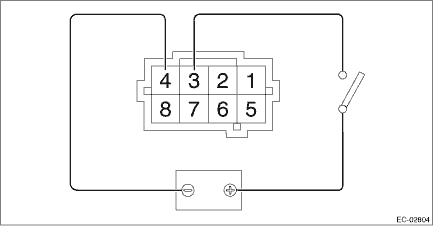

2. CHECK VACUUM PUMP

1. Connect the battery positive terminal to terminal No. 3 and the battery ground terminal to terminal No. 4, and inspect the vacuum pump operation.

CAUTION:

Do not operate the vacuum pump for 5 minutes or more.

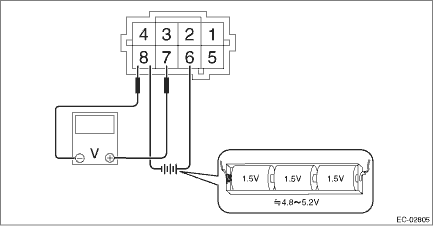

3. CHECK PRESSURE SENSOR

1. Connect dry-cell battery positive terminal to terminal No. 6 and dry-cell battery ground terminal to terminal No. 8, circuit tester positive terminal to terminal No. 7 and the circuit tester negative terminal to terminal No. 8.

NOTE:

• Use new dry-cell batteries.

• Using circuit tester, check the voltage of a single dry-cell battery is 1.6 V or more. And also check the voltage of three batteries in series is between 4.8 V and 5.2 V.

• For power supply, 5 V DC voltage source can also be used.

2. Check the voltage at a normal atmospheric pressure.

NOTE:

The atmospheric pressure at higher altitude is lower than normal. Therefore, the voltage is lower than the standard value.

Terminal No. | Standard |

7 (+) and 8 (−) | Approx. 3.5 V (when 25°C (77°F)) |

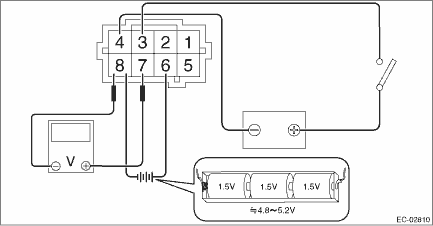

3. Connect the battery positive terminal to terminal No. 3 and the battery ground terminal to terminal No. 4, and check that there is a voltage drop from the voltage measured in step 2) when the vacuum pump is operated.

4. OTHER INSPECTIONS

1. Check that the leak check valve assembly has no deformation, cracks or other damages.

2. Check that the tube or hose have no cracks, damage or loose part.

Disassembly

Disassembly

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyDISASSEMBLY1. Remove the drain separator from the leak check valve assembly. Drain Separator > REMOVAL"> ...

Installation

Installation

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyINSTALLATION1. Install the leak check valve assembly to the vehicle with the bolt and clip (A).Tightening torque:7. ...

Other materials:

Installation

EXTERIOR/INTERIOR TRIM > Roof MoldingINSTALLATION1. Remove the clips from the molding - roof, and attach to the studs on the vehicle.CAUTION:• Always replace the clips that were damaged during removal of the molding - roof with new parts.• While installing the molding - roof, be caref ...

Disassembly

EMISSION CONTROL (AUX. EMISSION CONTROL DEVICES)(H4DO) > Leak Check Valve AssemblyDISASSEMBLY1. Remove the drain separator from the leak check valve assembly. Drain Separator > REMOVAL">2. Disconnect the drain tube from the leak check valve assembly.NOTE:Disconnect the quick connector ...

Preparation tool

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > General DescriptionPREPARATION TOOL1. SPECIAL TOOLILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS399411700ACCENT BALL INSTALLERUsed for installing reverse fork rod arm.899524100PULLER SETUsed for removing the front differential taper roller bearing.(1) Puller ...