Subaru Crosstrek Service Manual: Electrical specification

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > Control Module I/O Signal

ELECTRICAL SPECIFICATION

NOTE:

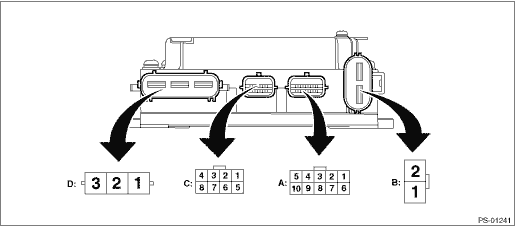

The terminal numbers of the power steering control module connectors are as indicated in the figure.

Contents | Terminal No. | Input/output signal |

Measured value and measuring conditions | ||

Power supply (IG SW) | A1 | Battery voltage is detected with the ignition switch ON when measuring between A1 — B1. |

Subaru Select Monitor communication line | A2 | Digital signal; can not be measured |

Shield GND | A3 | 0 V is constantly detected. |

Main torque sensor | A4 | The voltage changes when the steering is operated to the right or left with the ignition switch ON. |

Sub torque sensor | A5 | The voltage changes when the steering is operated to the right or left with the ignition switch ON. |

CAN communication | A6 | Digital signal; can not be measured |

CAN communication | A7 | Digital signal; can not be measured |

Torque sensor operating power supply | A8 | Approximately 8 V is detected with ignition switch ON. |

Torque sensor ground | A9 | 0 V is constantly detected. |

Torque sensor standard power supply | A10 | Approximately 3 V is detected with ignition switch ON. |

Ground | B1 | Battery voltage is constantly detected when measuring between B1 — B2. |

Power supply | B2 | |

Resolver S1 | C1 | Varies depending on the operational status of the motor. |

Resolver S3 | C2 | |

Resolver S2 | C3 | |

Resolver S4 | C4 | |

Excitation power supply for resolver | C5 | |

Common output | C6 | |

Motor U phase | D1 | Varies depending on the motor output. |

Motor V phase | D2 | |

Motor W phase | D3 |

Wiring diagram

Wiring diagram

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > Control Module I/O SignalWIRING DIAGRAM(1)Battery(5)Engine control module (ECM)(9)Torque sensor (main & sub)(2)Ignition switch(6)Power ste ...

Other materials:

Automatic Locking Retractor/Emergency Locking Retractor (ALR/ELR)

Each passenger's seatbelt has an Automatic

Locking Retractor/Emergency Locking

Retractor (ALR/ELR). The Automatic

Locking Retractor/Emergency Locking

Retractor normally functions as an Emergency

Locking Retractor (ELR). The ALR/

ELR has an additional locking mode

"Automatic Locking Retractor ...

Registering Bookmarks

You can register the music and artist now

being played in Bookmark.

1. Touch the tab.

2. Select the desired key. The following

items are appeared on the screen.

Item

Function

Track

When selected after the Bookmark

key is pressed, the current

track is bookmarked. ...

Wiring diagram

SECURITY AND LOCKS > Push Button Start SystemWIRING DIAGRAMFor wiring diagrams related to the push button start system (ignition change), refer to the following items.• Keyless access system: Keyless Access System > WIRING DIAGRAM">• Push button start system: Push Button ...