Subaru Crosstrek Service Manual: Inspection

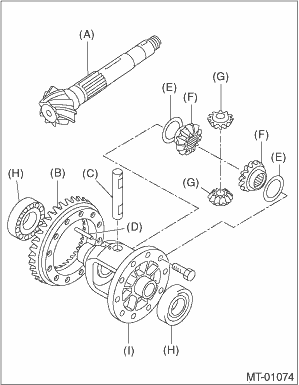

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Front Differential Assembly

INSPECTION

Repair or replace the differential gear in the following cases:

• When the hypoid driven gear and drive pinion shaft tooth surfaces are damaged, excessively worn, or seized.

• When the roller bearing on the drive pinion shaft has a worn or damaged roller path.

• When there is damage, wear or seizure of the differential bevel pinion, differential bevel gear, adjusting washer, pinion shaft or straight pin.

• When the differential case sliding surfaces are worn or damaged.

(A) | Drive pinion shaft |

(B) | Hypoid driven gear |

(C) | Pinion shaft |

(D) | Straight pin |

(E) | Adjusting washer |

(F) | Differential bevel gear |

(G) | Differential bevel pinion |

(H) | Taper roller bearing |

(I) | Differential case |

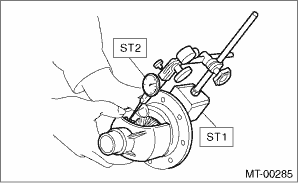

1. DIFFERENTIAL BEVEL PINION GEAR BACKLASH

Measure the backlash between the differential bevel gear and differential bevel pinion. Adjust the backlash if not within specified limit. Front Differential Assembly > ADJUSTMENT">

NOTE:

Be sure the bevel pinion gear teeth contact adjacent gear teeth during measurement.

Standard backlash

0.13 — 0.18 mm (0.0051 — 0.0071 in)

| ST1 498247001 | MAGNET BASE |

| ST2 498247100 | DIAL GAUGE |

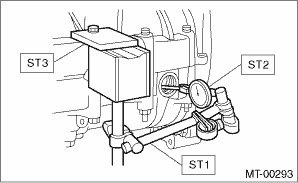

2. HYPOID DRIVEN GEAR BACKLASH

1. Set the ST1, ST2 and ST3. Insert the needle through drain plug hole so that the needle comes in contact with the tooth surface on the right corner, and check the backlash.

| ST1 498247001 | MAGNET BASE |

| ST2 498247100 | DIAL GAUGE |

| ST3 498255400 | PLATE |

2. Install SUBARU genuine axle shafts to both sides, rotate in the inversion direction so that the gauge contacts the tooth surface, and read the dial gauge.

NOTE:

If the backlash is outside the specified range, adjust it by turning the differential side retainer in the right side case.

Backlash

0.13 — 0.18 mm (0.0051 — 0.0071 in)

| Part No. 38415AA100 | Axle shaft |

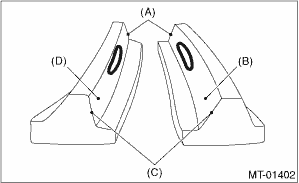

3. TOOTH CONTACT OF HYPOID DRIVEN GEAR

Check tooth contact of hypoid driven gear as follows: Apply a thin uniform coat of red lead on both teeth surfaces of three to four teeth of the driven gear. Move the driven gear back and forth by turning the main shaft until a definite contact pattern is developed on the driven gear, and judge whether face contact is correct. When the contact pattern is not correct, adjust. Front Differential Assembly > ADJUSTMENT">

• Tooth contact is correct.

(A) | Toe |

(B) | Coast side |

(C) | Heel |

(D) | Drive side |

Disassembly

Disassembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Front Differential AssemblyDISASSEMBLY1. DIFFERENTIAL CASE ASSEMBLY1. Remove the twelve bolts and remove hypoid driven gear.(A)Hypoid driven gear2. Drive ...

Installation

Installation

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Front Differential AssemblyINSTALLATION1. Install the differential side retainers using ST.ST 18630AA010WRENCH COMPL RETAINER2. Install the taper roll ...

Other materials:

Precautions against vehicle modification

Always consult your SUBARU dealer if

you want to install any accessory parts to

your vehicle.

CAUTION

Do not perform any of the following

modifications. Such modifications

can interfere with proper operation

of the seatbelt pretensioners.

Attachment of any equipment

(bush bar, winches, ...

Removal

GLASS/WINDOWS/MIRRORS > Front Door GlassREMOVAL1. Disconnect the ground cable from battery and wait for at least 60 seconds before starting work. NOTE">2. Remove the trim panel - front door. Door Trim > REMOVAL">3. Remove the sealing cover - front door. Front Sealing Cover & ...

Installation

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF) > Sunroof SwitchINSTALLATIONCAUTION:For installation of the stereo camera cover assembly, refer to “INSTALLATION”, “Stereo Camera” in the “EyeSight” section and observe the precautions for installation. Stereo Camera > ...