Subaru Crosstrek Service Manual: Dtc p2420 evap system switching valve control circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P2420 EVAP SYSTEM SWITCHING VALVE CONTROL CIRCUIT HIGH

DTC detecting condition:

Immediately at fault recognition

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

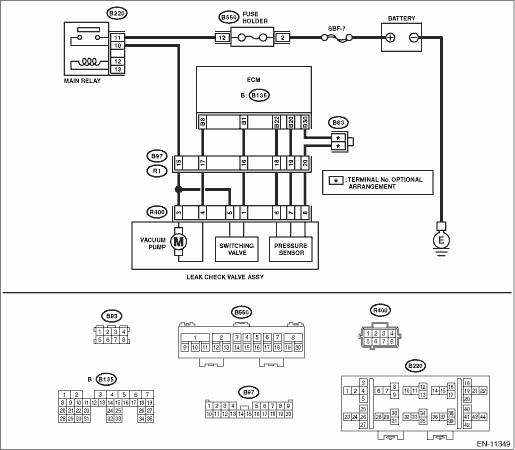

Wiring diagram:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK HARNESS BETWEEN ECM AND LEAK CHECK VALVE ASSEMBLY CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from the leak check valve assembly.

3) Turn the ignition switch to ON.

4) Measure the voltage between leak check valve assembly and chassis ground.

Connector & terminal

(R400) No. 1 (+) — Chassis ground (−):

Is the voltage 10 V or more?

Repair the short circuit to power in harness between ECM connector and leak check valve assembly connector.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P2420 EVAP SYSTEM SWITCHING VALVE CONTROL CIRCUIT HIGH">Go to Step 2.

2.CHECK LEAK CHECK VALVE ASSEMBLY.

1) Turn the ignition switch to OFF.

2) Check the switching valve of the leak check valve assembly. Leak Check Valve Assembly > INSPECTION">

Is the check result OK?

Repair the poor contact in the leak check valve assembly connector.

Replace the leak check valve assembly. Leak Check Valve Assembly">

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit in Evaporative Leak Check Module switching valve.

Judge as NG if out of specification.

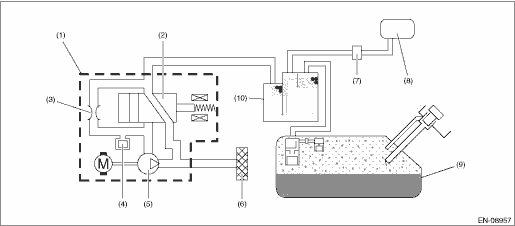

2. COMPONENT DESCRIPTION

(1) | Leak check valve ASSY | (5) | Vacuum pump | (9) | Fuel tank |

(2) | Switching valve | (6) | Drain filter | (10) | Canister |

(3) | Reference orifice (0.02 inch orifice) | (7) | Purge control solenoid valve | ||

(4) | Pressure sensor | (8) | Intake manifold |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

Battery voltage | ≥ 10.9 V |

Evaporative emission system switching valve command | ON |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Measured EVAP system switching valve current | ≥ 12 A |

Time Needed for Diagnosis: 2500 ms

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p2419 evap system switching valve control circuit low

Dtc p2419 evap system switching valve control circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2419 EVAP SYSTEM SWITCHING VALVE CONTROL CIRCUIT LOWDTC detecting condition:Immediately at fault recognition ...

Dtc p2530 ignition switch run position circuit

Dtc p2530 ignition switch run position circuit

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2530 IGNITION SWITCH RUN POSITION CIRCUITDTC detecting condition:Immediately at fault recognitionTrouble sym ...

Other materials:

Caution

POWER ASSISTED SYSTEM (POWER STEERING) (DIAGNOSTICS) > General DescriptionCAUTION1. SRS AIRBAG SYSTEMThe airbag system wiring harness is routed near the power steering control module.CAUTION:• Do not use the electrical test equipment on the airbag system wiring harnesses or connector circui ...

Assembly

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Center DifferentialASSEMBLYInstall the ball bearings.CAUTION:Do not apply a load in excess of 10 kN (1 ton, 1.1 US ton, 1.0 Imp ton).NOTE:Use a new ball bearing.(A)Ball bearing ...

Dtc p0604 internal control module random access memory (ram) error

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0604 INTERNAL CONTROL MODULE RANDOM ACCESS MEMORY (RAM) ERRORDTC DETECTING CONDITION:Detected when two consecutive driving cycles with fault occur.TROUBLE SYMPTOM:TCM RAM malfunctionSTEP ...