Subaru Crosstrek Service Manual: Dtc p0453 evap system (cpc) pressure sensor/switch circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)

DTC P0453 EVAP SYSTEM (CPC) PRESSURE SENSOR/SWITCH CIRCUIT HIGH

DTC detecting condition:

Immediately at fault recognition

CAUTION:

After servicing or replacing faulty parts, perform Clear Memory Mode Clear Memory Mode > OPERATION"> , and Inspection Mode Inspection Mode > PROCEDURE">

, and Inspection Mode Inspection Mode > PROCEDURE"> .

.

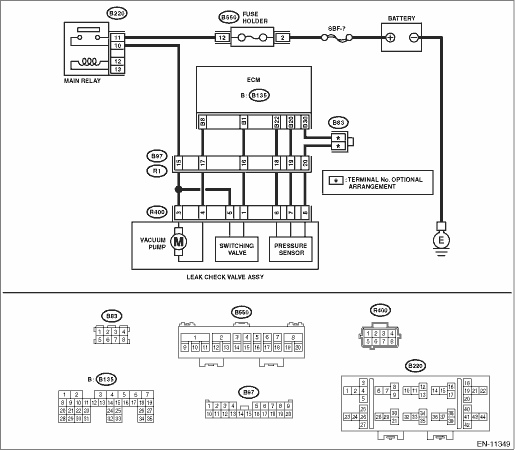

Wiring diagram:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK CURRENT DATA.

1) Turn the ignition switch to ON.

2) Read the value of «Atmosphere Pressure» using the Subaru Select Monitor or a general scan tool.

NOTE:

• Subaru Select Monitor

For detailed operation procedures, refer to “Current Data Display For Engine”. Subaru Select Monitor">

• General scan tool

For detailed operation procedures, refer to the general scan tool operation manual.

Is the value in «Atmosphere Pressure» 125 kPa (938 mmHg, 36.9 inHg) or more?

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0453 EVAP SYSTEM (CPC) PRESSURE SENSOR/SWITCH CIRCUIT HIGH">Go to Step 2.

Even if DTC is detected, the circuit has returned to a normal condition at this time. Reproduce the failure, and then perform the diagnosis again.

NOTE:

In this case, temporary poor contact of connector, temporary open or short circuit of harness may be the cause.

2.CHECK HARNESS BETWEEN ECM AND LEAK CHECK VALVE ASSEMBLY CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ECM.

3) Disconnect the connector from the leak check valve assembly.

4) Measure the resistance of harness between ECM connector and the leak check valve assembly connector.

Connector & terminal

(B135) No. 20 — (R400) No. 7:

(B135) No. 30 — (R400) No. 8:

Is the resistance less than 1 ??

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0453 EVAP SYSTEM (CPC) PRESSURE SENSOR/SWITCH CIRCUIT HIGH">Go to Step 3.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and the leak check valve assembly connector

• Poor contact of coupling connector

• Poor contact of joint connector

3.CHECK FOR POOR CONTACT.

Check for poor contact of ECM and the leak check valve assembly connector.

Is there poor contact in ECM and the leak check valve assembly connector?

Repair the poor contact of ECM and the leak check valve assembly connector.

Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0453 EVAP SYSTEM (CPC) PRESSURE SENSOR/SWITCH CIRCUIT HIGH">Go to Step 4.

4.CHECK LEAK CHECK VALVE ASSEMBLY.

Check the pressure sensor of the leak check valve assembly. Leak Check Valve Assembly > INSPECTION">

Is the check result OK?

Repair the short circuit to power in harness between ECM connector and leak check valve assembly connector.

Replace the leak check valve assembly. Leak Check Valve Assembly">

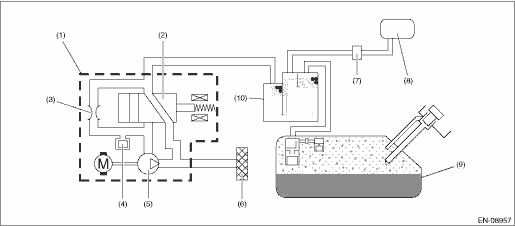

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit in Evaporative Leak Check Module pressure sensor.

Judge as NG if out of specification.

2. COMPONENT DESCRIPTION

(1) | Leak check valve ASSY | (5) | Vacuum pump | (9) | Fuel tank |

(2) | Switching valve | (6) | Drain filter | (10) | Canister |

(3) | Reference orifice (0.02 inch orifice) | (7) | Purge control solenoid valve | ||

(4) | Pressure sensor | (8) | Intake manifold |

3. EXECUTION CONDITION

Secondary Parameters | Execution condition |

12 V battery system voltage | ≥ 10.9 V |

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

If the duration of time while the following conditions are met is longer than the time indicated, judge as NG.

Malfunction Criteria | Threshold Value |

Output voltage | ≥ 4.095 V |

Time Needed for Diagnosis: 1000 ms

Malfunction Indicator Light Illumination: Illuminates as soon as a malfunction occurs.

Dtc p0452 evap system (cpc) pressure sensor/switch circuit low

Dtc p0452 evap system (cpc) pressure sensor/switch circuit low

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0452 EVAP SYSTEM (CPC) PRESSURE SENSOR/SWITCH CIRCUIT LOWDTC detecting condition:Immediately at fault recogn ...

Dtc p0455 evap system (cpc) leak detected (large leak)

Dtc p0455 evap system (cpc) leak detected (large leak)

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0455 EVAP SYSTEM (CPC) LEAK DETECTED (LARGE LEAK)DTC detecting condition:Detected when two consecutive drivi ...

Other materials:

Tire pressures and wear

Maintaining the correct tire pressures

helps to maximize the tires' service lives

and is essential for good running performance.

Check and, if necessary, adjust

the pressure of each tire (including the

spare - if equipped) at least once a month

(for example, during a fuel stop) and

before a ...

Removal

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Reverse Check SleeveREMOVAL1. Remove the manual transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the transfer case together with the extension case assembly. Transfer Case and Extension Case Assembly ...

Preparing to drive

You should perform the following checks

and adjustments every day before you

start driving.

1. Check that all windows, mirrors, and

lights are clean and unobstructed.

2. Check the appearance and condition

of the tires. Also check tires for proper

inflation.

3. Look under the vehicle fo ...