Subaru Crosstrek Service Manual: Disassembly

BRAKE > Rear Disc Brake Assembly

DISASSEMBLY

CAUTION:

Be careful not to allow foreign matter to enter the brake hose connector.

1. Remove mud and foreign matter from the caliper body assembly.

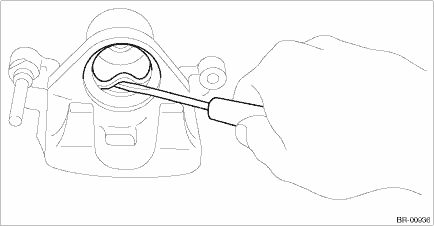

2. Remove the piston boot from caliper body cylinder.

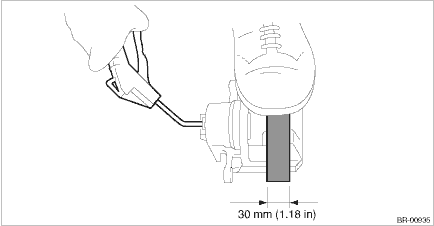

3. Remove the piston - disc brake.

(1) Place a wooden block in the caliper body assembly as shown in the figure to prevent the piston - disc brake from jumping out and being damaged.

(2) Using an air gun, gradually apply compressed air via the brake hose installation hole to push out the piston - disc brake.

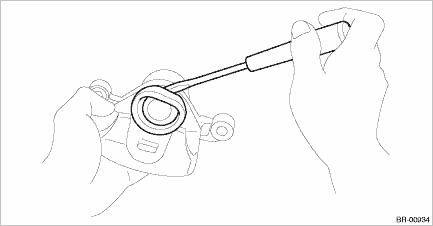

4. Remove the piston seal from caliper body cylinder.

CAUTION:

Do not damage the cylinder and piston seal groove.

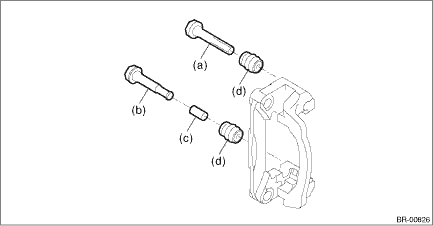

5. Remove the guide pin - rear brake, lock pin - rear brake, lock pin - sleeve, and pin boot from the support - rear disc brake.

(a) | Guide pin - rear brake (black) | (c) | Lock pin - sleeve | (d) | Pin boot |

(b) | Lock pin - rear brake (silver) |

Removal

Removal

BRAKE > Rear Disc Brake AssemblyREMOVALCAUTION:Do not allow brake fluid to come in contact with the painted surface of the vehicle body. If it does, wash off with water and wipe away completely.1. ...

Inspection

Inspection

BRAKE > Rear Disc Brake AssemblyINSPECTION1. Check the caliper body cylinder and piston - disc brake for uneven wear, damage or rust.2. Check the rubber parts for damage or deterioration.3. If faul ...

Other materials:

Removal

CONTINUOUSLY VARIABLE TRANSMISSION(TR580) > Reduction Driven GearREMOVAL1. Remove the transmission assembly from the vehicle. Automatic Transmission Assembly > REMOVAL">2. Remove the extension case. Extension Case > REMOVAL">3. Remove the transfer clutch assembly. Transfe ...

Dtc u0140 lost communication with body control module

TELEMATICS SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0140 LOST COMMUNICATION WITH BODY CONTROL MODULEDetected when CAN data is not received from body integrated unit.NOTE:Perform the diagnosis for LAN system. Basic Diagnostic Procedure > PROCEDURE" ...

Dtc c0074 master cylinder pressure sensor output

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C0074 MASTER CYLINDER PRESSURE SENSOR OUTPUTDTC detecting condition:Defective pressure sensorTrouble symptom:• ABS does not operate.• VDC does not operate.• EyeSight does no ...