Subaru Crosstrek Service Manual: Diagnostic procedure for subaru select monitor communication Communication for initializing impossible

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure for Subaru Select Monitor Communication

COMMUNICATION FOR INITIALIZING IMPOSSIBLE

DIAGNOSIS:

Open or short circuit in data link connector

TROUBLE SYMPTOM:

Subaru Select Monitor communication failure

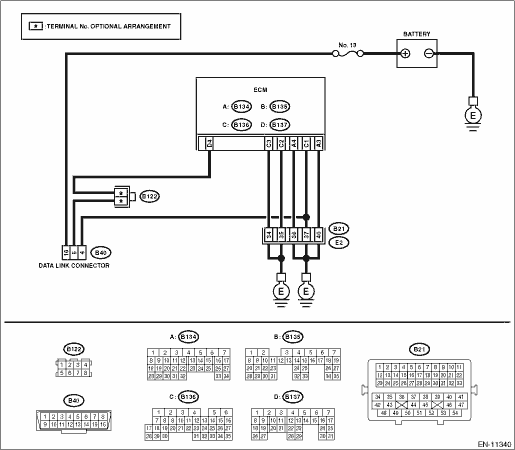

WIRING DIAGRAM:

Engine electrical system Engine Electrical System">

| STEP | CHECK | YES | NO |

1.CHECK POWER SUPPLY CIRCUIT.

Connect DST-i or general scan tool to data link connector.

Does DST-i or the general scan tool turn ON?

Diagnostic Procedure for Subaru Select Monitor Communication > COMMUNICATION FOR INITIALIZING IMPOSSIBLE">Go to Step 4.

Diagnostic Procedure for Subaru Select Monitor Communication > COMMUNICATION FOR INITIALIZING IMPOSSIBLE">Go to Step 2.

2.CHECK POWER SUPPLY CIRCUIT.

Measure the voltage between data link connector and chassis ground.

Connector & terminal

(B40) No. 16 (+) — Chassis ground (−):

Is the voltage 10 V or more?

Diagnostic Procedure for Subaru Select Monitor Communication > COMMUNICATION FOR INITIALIZING IMPOSSIBLE">Go to Step 3.

Repair the power supply circuit.

NOTE:

In this case, repair the following item:

• Open or ground short circuit of harness between battery and data link connector

• Blown out of fuse (M/B No. 13)

3.CHECK HARNESS BETWEEN DATA LINK CONNECTOR AND CHASSIS GROUND.

1) Turn the ignition switch to OFF.

2) Measure the resistance of harness between data link connector and chassis ground.

Connector & terminal

(B40) No. 4 — Chassis ground:

(B40) No. 5 — Chassis ground:

Is the resistance less than 5 ??

Repair the poor contact of data link connector.

Repair the harness and connector.

NOTE:

In this case, repair the following item:

• Open circuit in harness between ECM connector and data link connector

• Open circuit of harness between ECM connector and engine ground

• Poor contact of ECM connector

• Poor contact of coupling connector

4.CHECK HARNESS BETWEEN ECM AND DATA LINK CONNECTOR.

Measure the resistance between data link connector and chassis ground.

Connector & terminal

(B40) No. 7 — Chassis ground:

Is the resistance 1 M? or more?

Repair the poor contact of the ECM or data link connector.

Repair the short circuit to ground in harness between ECM connector and data link connector.

Data link connector Note

Data link connector Note

ENGINE (DIAGNOSTICS)(H4DO) > Data Link ConnectorNOTEThis connector is used for Subaru Select Monitor.CAUTION:Do not connect any scan tools other than Subaru Select Monitor or general scan tool beca ...

Drive cycle Procedure

Drive cycle Procedure

ENGINE (DIAGNOSTICS)(H4DO) > Drive CyclePROCEDUREIt is necessary to perform the drive cycle listed below if DTC is not found in the Inspection Mode. It is possible to complete diagnosis of the DTC ...

Other materials:

Preparation tool

AIRBAG SYSTEM > General DescriptionPREPARATION TOOL1. SPECIAL TOOL• TEST HARNESS NILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS98299SA000TEST HARNESS NUsed for unit inspection of steering roll connector.• TEST HARNESS QILLUSTRATIONTOOL NUMBERDESCRIPTIONREMARKS98299SA040TEST HARNESS QUsed ...

Inspection

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft AssemblyINSPECTIONDisassembled parts should be washed with cleaning solvent first, then inspected carefully.1. BearingReplace the bearings in the following cases.• When the bearing balls, outer races and inner races are broken or rusty. ...

Precautions in trouble diagnosis and repair of electric parts

WIRING SYSTEM > Working PrecautionsPRECAUTIONS IN TROUBLE DIAGNOSIS AND REPAIR OF ELECTRIC PARTS1. The battery cable must be disconnected from the battery’s (−) terminal, and the ignition switch must be set to the OFF position, unless otherwise required by the diagnostics.2. Securely ...