Subaru Crosstrek Service Manual: Component

STARTING/CHARGING SYSTEMS(H4DO) > General Description

COMPONENT

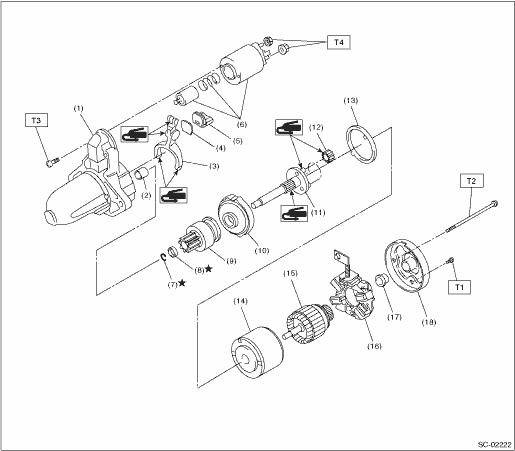

1. STARTER

(1) | Starter housing ASSY | (9) | Overrunning clutch | (17) | Sleeve bearing |

(2) | Sleeve bearing | (10) | Internal gear ASSY | (18) | Starter cover ASSY |

(3) | Shift lever | (11) | Shaft | ||

(4) | Plate | (12) | Pinion gear | Tightening torque: N·m (kgf-m, ft-lb) | |

(5) | Seal rubber | (13) | Seal rubber | T1: | 1.4 (0.1, 1.0) |

(6) | Magnet switch ASSY | (14) | Yoke ASSY | T2: | 6 (0.6, 4.4) |

(7) | Snap ring | (15) | Armature ASSY | T3: | 7.5 (0.8, 5.5) |

(8) | Stopper | (16) | Brush holder ASSY | T4: | 10 (1.0, 7.4) |

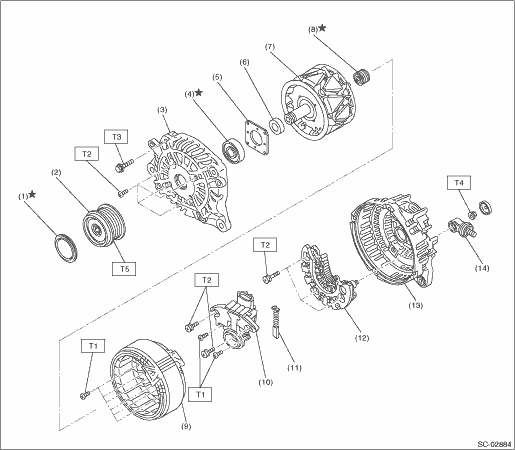

2. GENERATOR

(1) | Cap | (8) | Bearing | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Pulley | (9) | Stator coil | T1: | 2 (0.2, 1.5) |

(3) | Front cover | (10) | IC regulator | T2: | 3.9 (0.4, 2.9) |

(4) | Ball bearing | (11) | Brush | T3: | 4.4 (0.4, 3.2) |

(5) | Bearing retainer | (12) | Rectifier | T4: | 8.9 (0.9, 6.6) |

(6) | Spacer | (13) | Rear cover | T5: | 108 (11.0, 79.8) |

(7) | Rotor | (14) | Terminal B | ||

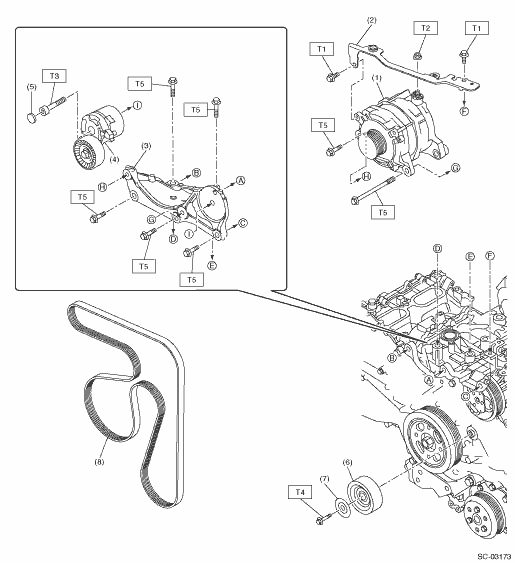

3. GENERATOR BRACKET

(1) | Generator | (7) | Idler pulley cover | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | V-belt cover bracket | (8) | V-belt | T1: | 6.4 (0.7, 4.7) |

(3) | Generator bracket | T2: | 15.5 (1.6, 11.4) | ||

(4) | V-belt tensioner ASSY | T3: | 25 (2.5, 18.4) | ||

(5) | Cap | T4: | 36 (3.7, 26.6) | ||

(6) | Idler pulley | T5: | Generator > INSTALLATION"> | ||

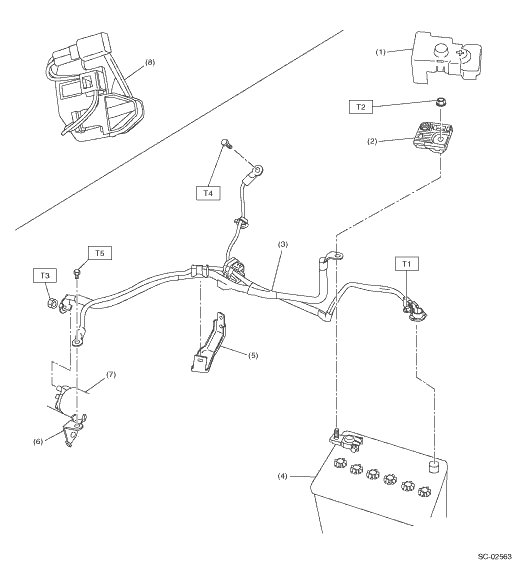

4. BATTERY CURRENT & TEMPERATURE SENSOR

(1) | Terminal boot | (7) | Starter | Tightening torque: N·m (kgf-m, ft-lb) | |

(2) | Terminal fuse ASSY | (8) | Battery temperature sensor | T1: | 6 (0.6, 4.4) |

(3) | Battery cable ASSY | T2: | 7.5 (0.8, 5.5) | ||

(4) | Battery | T3: | 11 (1.1, 8.1) | ||

(5) | Battery cable bracket | T4: | 13 (1.3, 9.6) | ||

(6) | Battery cable stay | T5: | 14 (1.4, 10.3) | ||

Specification

Specification

STARTING/CHARGING SYSTEMS(H4DO) > General DescriptionSPECIFICATIONItemSpecificationsVehicle modelCVTMTStarterTypeReduction typeModelM000T38571M000T33176ManufacturerMitsubishi ElectricVoltage and ou ...

Preparation tool

Preparation tool

STARTING/CHARGING SYSTEMS(H4DO) > General DescriptionPREPARATION TOOL1. GENERAL TOOLTOOL NAMEREMARKSCircuit testerUsed for measuring resistance, voltage and current.NOTE:• For measuring stand ...

Other materials:

Dtc p0123 throttle/pedal position sensor/switch "a" circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0123 THROTTLE/PEDAL POSITION SENSOR/SWITCH "A" CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Improper idling• Engine stall• Poor driving per ...

Dtc c1332 rr pressure reducing valve

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC C1332 RR PRESSURE REDUCING VALVENOTE:For the diagnostic procedure, refer to “DTC C1362 NORMAL CLOSING VALVE 2”. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC C ...

Read current data Operation

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS) > Read Current DataOPERATIONCheck the operating condition of each sensor in the event of malfunction in the seat belt buckle switch, or when the seat belt buckle switch has been replaced.NOTE:For detailed operation procedures, refer to “Application he ...