Subaru Crosstrek Service Manual: Assembly

CONTROL SYSTEMS > Select Lever

ASSEMBLY

1. Clean all the parts before assembly.

2. Apply Multemp D or equivalent to the sliding portion of each part.

3. Assemble in the reverse order of disassembly.

NOTE:

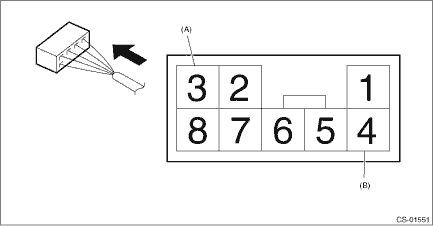

Insert the solenoid unit terminals to the harness connector.

(A) | Solenoid unit (color code: blue) |

(B) | Solenoid unit (color code: black) |

4. After installation, check the following points.

• The select indicator matches the select lever position when the select lever is changed from “P” range to “D” range.

• The select lever position and the position mark match each other.

• Operating force to move the select lever from “P” to “D” range

Select lever

Select lever

...

Removal

Removal

CONTROL SYSTEMS > Select LeverREMOVAL1. Shift the select lever to “N” range.2. Disconnect the ground cable from battery. NOTE">NOTE:For model with battery sensor, disconnect th ...

Other materials:

Inspection

LUBRICATION(H4DO) > Engine OilINSPECTIONCAUTION:If the engine oil is spilt over exhaust pipe or the under cover, wipe it off with cloth to avoid emitting smoke or causing a fire.1. Park the vehicle on a level surface.2. Turn the ignition switch to OFF.3. Remove the oil level gauge and wipe away t ...

Dtc p0353 ignition coil "c" primary control circuit/open

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0353 IGNITION COIL "C" PRIMARY CONTROL CIRCUIT/OPENNOTE:For the diagnostic procedure, refer to DTC P0351. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P0351 IGNITION COIL " ...

Dtc p0843 transmission fluid pressure sensor/switch "a" circuit high

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P0843 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH "A" CIRCUIT HIGHDTC detecting condition:Immediately at fault recognitionTrouble symptom:Shift characteristics malfunctionCAUTION: ...