Subaru Crosstrek Service Manual: Removal

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel Level Sensor

REMOVAL

WARNING:

Place “NO OPEN FLAMES” signs near the working area.

CAUTION:

• Be careful not to spill fuel.

• If the fuel gauge indicates that two thirds or more of the fuel is remaining, be sure to drain fuel before starting work to avoid the fuel to spill.

NOTE:

The fuel level sensor is built in fuel pump assembly.

1. Remove the fuel pump assembly. Fuel Pump > REMOVAL">

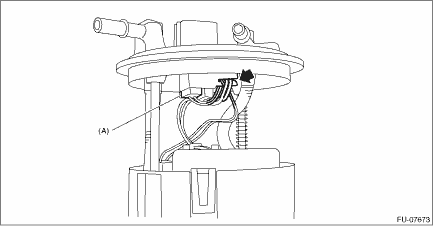

2. Disconnect the fuel level sensor connector (A), and pull out the connector cable and fuel level sensor harness from the clip.

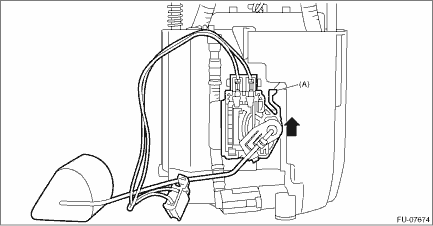

3. While pressing the claw (A) of the fuel level sensor, slide the fuel level sensor in the direction of the arrow, and remove the fuel level sensor.

Inspection

Inspection

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel Level SensorINSPECTION1. Check that the fuel level sensor has no damage.2. Measure the fuel level sensor float position.NOTE:When inspecting the fuel leve ...

Installation

Installation

FUEL INJECTION (FUEL SYSTEMS)(H4DO) > Fuel Level SensorINSTALLATIONInstall in the reverse order of removal.CAUTION:Be sure to install the fuel level sensor harness to the clip first, then install t ...

Other materials:

Dtc u0122 lost communication with vehicle dynamics control module

INSTRUMENTATION/DRIVER INFO (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC U0122 LOST COMMUNICATION WITH VEHICLE DYNAMICS CONTROL MODULEDetected when CAN data from VDC does not arrive.NOTE:Perform the diagnosis for LAN system. Basic Diagnostic Procedure > PROCEDURE ...

Removal

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Shifter Fork and RodREMOVAL1. Remove the manual transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the back-up light switch and the neutral position switch. Switches and Harness > REMOVAL">3 ...

Dtc p014c a/f / o2 sensor slow response - rich to lean bank 1 sensor 1

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P014C A/F / O2 SENSOR SLOW RESPONSE - RICH TO LEAN BANK 1 SENSOR 1DTC DETECTING CONDITION:Detected when two consecutive driving cycles with fault occur.CAUTION:After servicing or replacing faulty parts, perfor ...