Subaru Crosstrek Service Manual: Preparation tool

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS) > General Description

PREPARATION TOOL

CAUTION:

To measure the voltage and resistance of airbag system and occupant detection system components, be sure to use the specified test harness.

1. SPECIAL TOOL

ILLUSTRATION | TOOL NUMBER | DESCRIPTION | REMARKS |

—

SUBARU SELECT MONITOR 4

Used for setting of each function and troubleshooting for electrical system.

NOTE:

For detailed operation procedures of Subaru Select Monitor 4, refer to “Application help”.

• TEST HARNESS Y

ILLUSTRATION | TOOL NUMBER | DESCRIPTION | REMARKS |

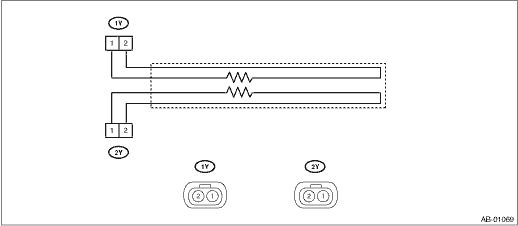

98299AG040

TEST HARNESS Y

Used for troubleshooting seat belt buckle switch.

• TEST HARNESS AE

ILLUSTRATION | TOOL NUMBER | DESCRIPTION | REMARKS |

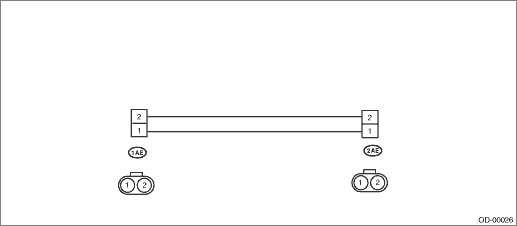

98299XA030

TEST HARNESS AE

TEST HARNESS Y adapter harness.

Used for troubleshooting seat belt buckle switch.

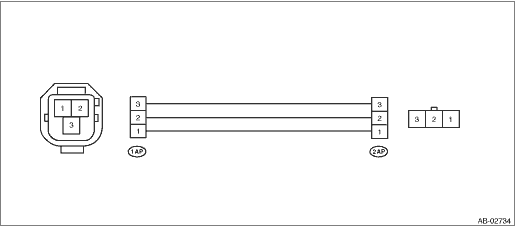

• TEST HARNESS AP

ILLUSTRATION | TOOL NUMBER | DESCRIPTION | REMARKS |

98299FJ030

TEST HARNESS AP

Used when measuring voltage and resistance of occupant detection system.

2. GENERAL TOOL

TOOL NAME | REMARKS |

Circuit tester | Used for measuring resistance, voltage and current. |

DST-i | Used together with Subaru Select Monitor 4. |

Caution

Caution

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS) > General DescriptionCAUTION1. The occupant detection system (passenger seat only) control module and the occupant detection sensor are fixed to the seat cus ...

Inspection

Inspection

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS) > General DescriptionINSPECTIONCheck the battery. Battery"> ...

Other materials:

Note

ENTERTAINMENT > Telematics SystemNOTEFor procedure of each component in the telematics system, refer to the respective section.• Data communication module: Data Communication Module">• Antenna: Antenna">• GPS antenna: GPS Antenna">• Switches and ...

Installation

WIPER AND WASHER SYSTEMS > Rear Wiper MotorINSTALLATION1. Install each part in the reverse order of removal.2. Check that the mark on the cap - pivot wiper faces up, as shown in the figure.Tightening torque:Refer to “COMPONENT” of “General Description”. General Descriptio ...

Installation

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF) > SunshadeINSTALLATIONCAUTION:For installation of the stereo camera cover assembly, refer to “INSTALLATION”, “Stereo Camera” in the “EyeSight” section and observe the precautions for installation. Stereo Camera > INST ...