Subaru Crosstrek Service Manual: Note Note

NOTE

NOTE

This information will improve the efficiency of maintenance and assure the sound work.

1. CLEANING

• Perform the operation in a clean location and use extra caution in dust proofing.

• Clean the items (except for assembly components) with steam, etc. before disassembly. During steam cleaning, wrap the air breather, oil level gauge, connectors, etc. with vinyl tape to prevent steam from entering inside the parts.

• Use an appropriate cleaning solvent.

• Do not clean rubber parts such as O-ring, gasket and oil seal with cleaning solution.

2. FASTENERS NOTICE

Tighten the bolts and nuts to the specified torque.

Do not apply paint, lubricant, rust retardant or other substance to the surface around bolts, nuts, etc. It may cause troubles with tightening to the specified torque and result in looseness and other problems of bolts and nuts.

3. ABOUT SCREWS

Use an appropriate sized tool. Insert a screw vertically into the hole. Check for any loose screws after installation.

If improper tools are used or screws are inserted obliquely to the hole, the screws cannot be installed correctly, which may result in insufficient tightening force or damage on the hole.

4. STATIC ELECTRICITY DAMAGE

Do not touch the control modules, connectors, logic boards and other such parts when there is a risk of static electricity. Always use a static electricity prevention cord or touch grounded metal for the elimination of static electricity before conducting work.

5. TROUBLESHOOTING OF ELECTRICAL SYSTEM

1. Always refer to “CAUTION” of “General Description” in the same models service manual before starting the diagnostics and repair.

2. Always refer to the cautions of each section when diagnosing and repairing each system and component.

3. The battery cable must be disconnected from the negative terminal after the ignition switch is set to the OFF position, unless otherwise required by the diagnostics.

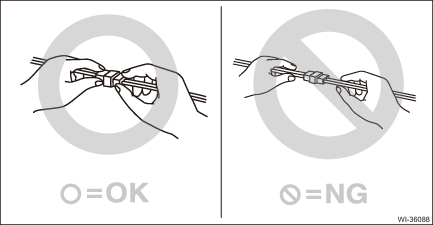

4. When disconnecting a connector, do not pull the harness, but pull while holding the connector housing.

5. Confirm the locking shape completely before disconnecting a connector. In addition, firmly push in the connector until a click sounds when connecting a connector.

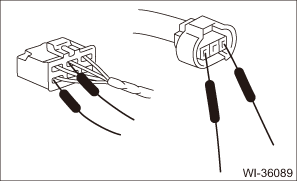

6. When checking continuity between connector terminals, or measuring voltage across the terminal and ground, always touch tester probe(s) to terminals from the harness side.

If the probe is too thick to gain access to the terminal, do not push it in forcibly but use a mini test lead.

7. When measuring the voltage or resistance of individual sensor or all electrical control modules, use a tapered pin with a diameter of 0.6 mm (0.024 in) or less and touch it to the tip of terminal. Never insert the tapered pin into the terminal at this time. Doing so may cause internal deformation and a malfunction can occur.

CAUTION:

If a taper pin or the like has been inserted into the connector terminal, replace the connector.

8. To check water-proof connectors (which are not measurable from the harness side), touch tester probes on the terminal side and be very careful not to bend or damage the terminals.

9. Securely fasten the harness with clamps and clips so that the harness does not interfere with the body end parts, edges, bolts or screws.

10. When installing a harness and a component, be careful not to catch them on the harness.

11. Sensors, relays, units, etc., are sensitive to strong impacts. Handle them with extra care so that they are not dropped or mishandled.

12. Because the HID headlight uses high voltage, be sure to confirm that the power supply is turned off before diagnostics and repair. Furthermore, do not perform diagnostics and repair with wet hands because there is a possibility of electrical shock.

13. When inspecting the airbag system, in order to avoid malfunction, always refer to “CAUTION” of “General Description” of the airbag system in the same model’s service manual.

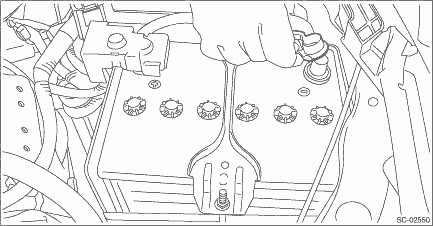

6. BATTERY

When removing the battery terminal, always be sure to turn the ignition switch to OFF and disconnect the battery ground terminal first.

• Disconnect the ground cable from battery.

• Install in the reverse order.

NOTE:

• Clean the battery cable terminals and apply grease to retard the formation of corrosion.

• Connect the positive (+) terminal, and then connect the negative (-) terminal of the battery.

• After the battery is installed, initial diagnosis of the electronic throttle control is performed. Wait for 10 seconds or more after turning the ignition switch to ON, and then start the engine.

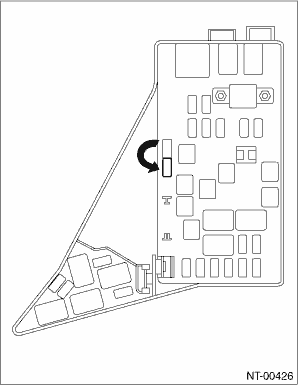

7. BACKUP/POWER SUPPLY FUSE

Backup fuse (20A) remains removed to prevent the battery consumption when vehicles are delivered. Install the backup fuse by following the illustration.

8. IMMOBILIZER RELATED PART

• Do not replace the immobilizer related parts with the parts from other vehicle.

• Registration of the immobilizer is necessary when a immobilizer-related control module has been replaced. For detailed operation procedure, refer to the “REGISTRATION MANUAL FOR IMMOBILIZER” provided as a separate volume.

9. SERVICE PARTS

Use genuine parts for maximum performance and maintenance when conducting repairs. Subaru/FHI will not be responsible for poor performance resulting from the use of parts except for genuine parts.

10. PROTECTING VEHICLE UNDER MAINTENANCE

Make sure to attach the fender cover, seat covers, etc. before work.

11. ENSURING SECURITY DURING WORK

When working in a group of two or more, perform the work with calling each other to ensure mutual safety.

12. LIFT AND JACK

When using a lift or shop jack to raise a vehicle or using rigid rack to support a vehicle, always follow instructions concerning jack-up points and weight limits to prevent the vehicle from falling, which could result in injury. Be especially careful that the vehicle is balanced before raising it. Be sure to set the wheel stoppers when jacking-up only the front or rear side of the vehicle.

CAUTION:

Select the lift attachment so that the side sill does not contact the lift arm.

NOTE:

• When using a lift, follow its operation manual.

• When the side sill cover contacts the lift arm, use a lift attachment.

• Do not work or leave unattended while the vehicle is supported with jack, support it with rigid racks.

• Be sure to use the rigid racks with rubber attached to cradle to support the vehicle.

• When using a lift, use an attachment or something similar.

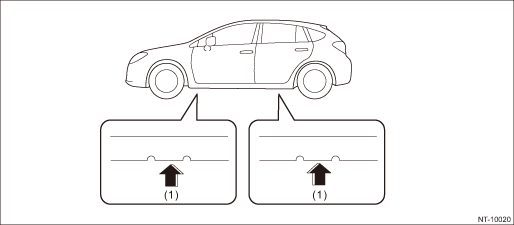

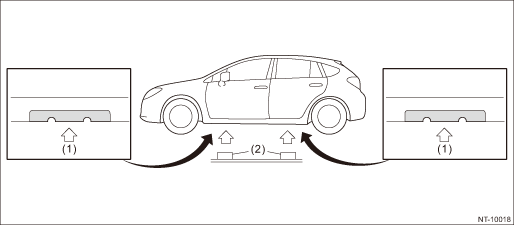

• When using a plate lift, use a rubber attachment. Place the attachment to the specified position of the vehicle, by adjusting front/rear and left/right sides accordingly.

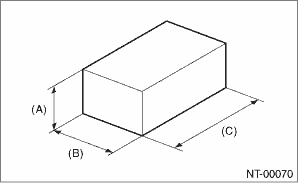

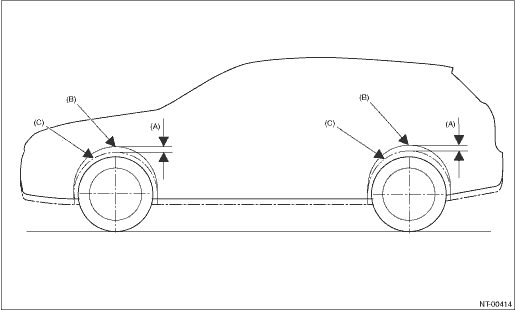

(A) | 80 mm (3.1 in) or more |

(B) | 80 — 100 mm (3.15 — 3.94 in) |

(C) | 120 — 200 mm (4.72 — 7.87 in) |

• Align the cushion rubber center part of plate lift with the center part of rubber attachment.

• Do not use the plate lift whose attachment does not reach the supporting locations.

• Support locations

(1) | Jack-up point |

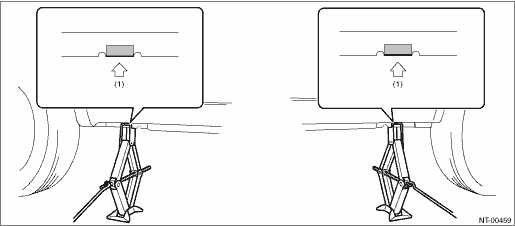

• Pantograph jack

(1) | Jack-up point |

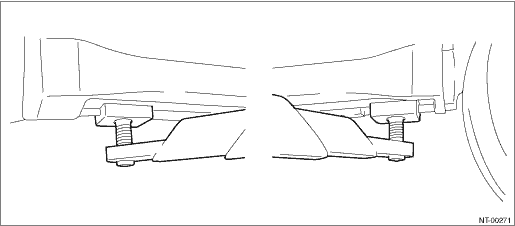

• Lift

CAUTION:

For models with spoiler garnish, use a spacer or an attachment to lift up the vehicle securely at jack up point without the side garnish contacting the lift.

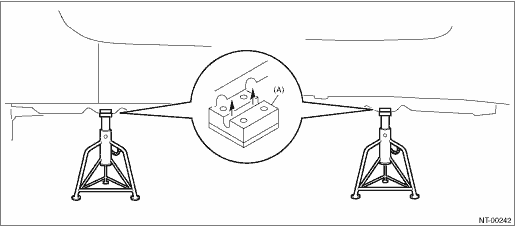

• Rigid rack

(A) | Attachment |

• Plate lift

(1) | Jack-up point | (2) | Attachment |

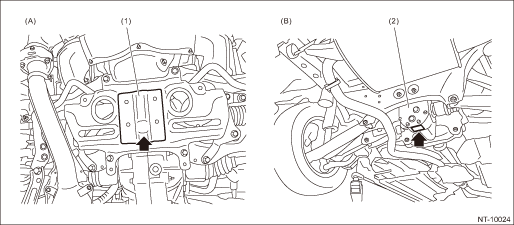

• Jack-up point (when using a garage jack)

(A) | Front | (B) | Rear | ||

(1) | Front crossmember support | (2) | Rear differential |

CAUTION:

If jacking up the front side of the vehicle, make sure that the jack is attached at the center of the jack-up plate not at the sides.

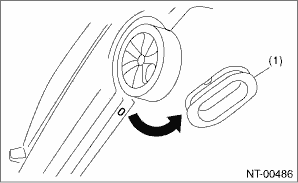

13. TIE-DOWNS

Tie-downs are used when transporting vehicles and when using the chassis dynamo. Remove the grommet of the tie-down hole and install the tie-down only to the specified locations on the vehicle.

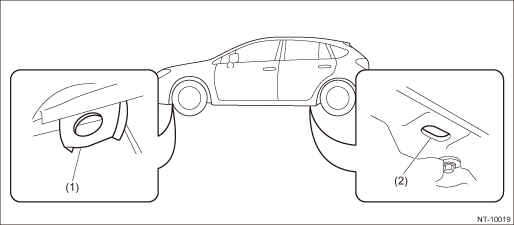

(1) | Grommet |

• Tie-down location

(1) | Hook for tie-down | (2) | Tie-down hole |

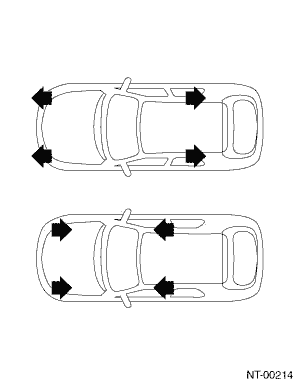

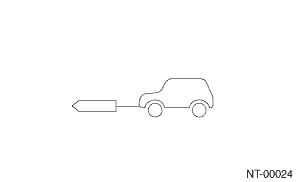

• Chain direction at tie-down condition

CAUTION:

• Pull the front and rear of the vehicle in the opposite direction, and pull the left and right of the vehicle in the same direction.

• Patterns except for the followings (recommended) are not allowed.

Recommended | |

Tie-down direction |

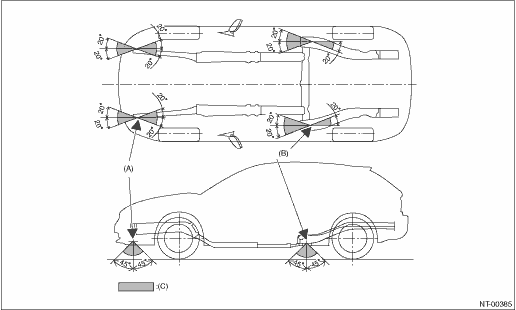

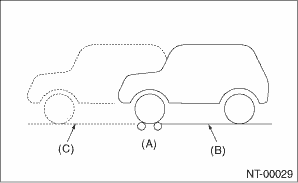

• Tie-down range

For ground transportation

CAUTION:

When the vehicle is tied down from vehicle inside, hook the hooks of tie-down chain on the rear tie-down holes from vehicle inside. When the vehicle is tied down from vehicle outside, hook the hooks of tie-down chain on the rear tie-down hooks from vehicle outside.

(A) | Front tie-down hook | (B) | Rear tie-down hole | (C) | Chain pulling range at tie-down condition |

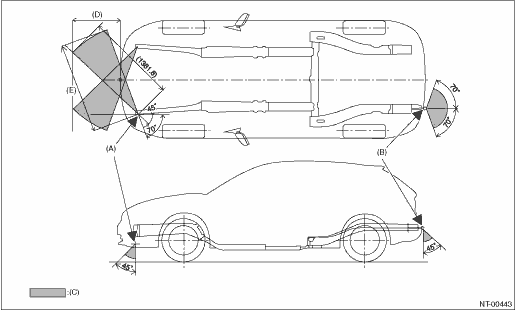

For sea transportation

CAUTION:

The eyebolts are exclusively used for towing and sea transportation tie-down, and do not use them for ground and freight transportation.

(A) | Front tie-down hook | (C) | Chain pulling range at tie-down condition | (E) | 1,320 mm (52.0 in) |

(B) | Eyebolt | (D) | 400 mm (15.7 in) |

• Vehicle sinking volume at tie-down condition

CAUTION:

The vehicle sinking volume at tie-down condition should be less than 50 mm (1.97 in) and make sure to fix the vehicle securely.

Check to see if the tensions of chains or belts at tie-down condition are appropriate in the following procedures.

1. Before tie-down, measure the distance between the highest tire point and highest arch point at the center of wheel.

2. After tie-down, measure the distance between the highest tire point and highest arch point at the center of wheel.

3. If the distance (A) between the measured value of 1) and 2) above, is less than 50 mm (1.97 in), it is judged as OK. If the distance is 50 mm (1.97 in) or more, it is judged as NG because the tension is too high.

(B) | Arch position before tie-down | (C) | Arch position after tie-down |

• Notes for the use of tie-down hook

When the vehicle is tied down from vehicle inside, hook the hooks of tie-down chain from vehicle inside, and when the vehicle is tied down from vehicle outside, hook the hooks of tie-down chain from vehicle outside.

For front tie-down hook, use S hook and J hook, and for rear tie-down hole, use S hook, J hook and T hook. T hook can be used only for rear tie-down hole.

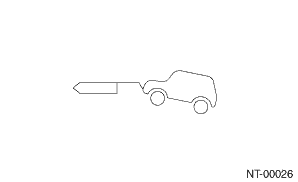

14. TOWING

Avoid towing vehicles except when the vehicle cannot be driven. For models with AWD, CVT or VTD, use a loader instead of towing. When towing other vehicles, pay attention to the following to prevent hook or vehicle damage resulting from excessive weight.

• Do not tow other vehicles with a front tie-down hook.

• Make sure the vehicle towing is heavier than the vehicle being towed.

• When towing the vehicle equipped with Subaru EyeSight, be sure to hold down the pre-collision brake OFF switch to turn OFF the pre-collision brake function. (Check that the pre-collision brake OFF indicator light in the meter lights up.)

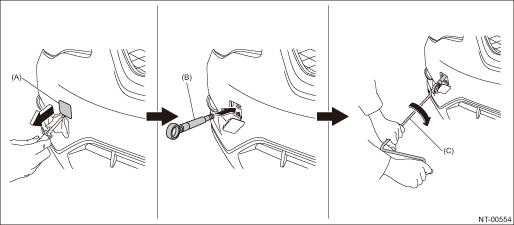

• Front

Remove the hook cover, and install the towing hook (eyebolt).

CAUTION:

Make sure to detach the towing hook (eyebolt) after towing. If the hook remains attached, airbag may not operate properly when receiving a shock from front side. And it may also affect the crash performance of the vehicle.

(A) | Hook cover | (B) | Towing hook (eyebolt) | (C) | Jack handle |

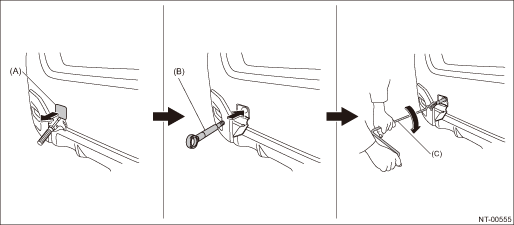

• Rear

Remove the hook cover, and install the towing hook (eyebolt).

CAUTION:

Make sure to detach the towing hook (eyebolt) after towing. If the hook remains attached, the fuel leakage control function of the fuel pump may not operate properly when receiving a shock from rear side. And it may also affect the crash performance of the vehicle.

(A) | Hook cover | (B) | Towing hook (eyebolt) | (C) | Jack handle |

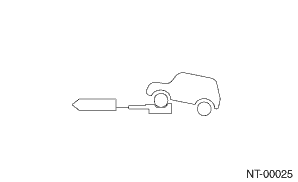

• Precautions

Towing | Precautions | MT | CVT |

Lifting up four wheels (on a trailer) |

Towing the vehicle after lifting up all four wheels is a basic rule for AWD model.

Rope

• Check if both front and rear wheels are rotated normally.

• CVT model driving conditions: Driving speed of 30 km/h (19 MPH) or less

Allow driving distance 50 km (31 miles) or less

Raising the front wheels

Prohibited for full-time AWD model.

Lifting up the front wheels

• Prohibited, due to damage on bumper, front grille, etc.

• Do not raise the vehicle with bumper.

Marked  : OK, Marked

: OK, Marked  : Prohibited, Marked

: Prohibited, Marked  : Conditionally OK

: Conditionally OK

CAUTION:

• Place the shift lever in “N” position during towing.

• Do not lift up the rear wheels to avoid unsteady rotation.

• Turn the ignition key to “ACC”, then check the steering wheel moves freely. (Models without the keyless access with push button start)

• Turn the ignition switch to “ACC” or “ON” position, and check that the steering wheel moves freely. (Model with keyless access with push button start)

• Release the parking brake to avoid tire dragging.

• Since the power steering does not work, be careful for the heavy steering effort. (When engine is stopped)

• Since the servo brake does not work, be careful that the brake is not applied effectively. (When engine is stopped)

• In case of the malfunction of internal transmission or drive system, lift up four wheels (on a trailer) for towing.

• Do not use towing hook (eyebolt) except when towing.

• While being towed with all four wheels on the ground, turn the engine switch to ON but do not start the engine.

• If the vehicle is towed using a rope, the pedestrian alert may sound when the vehicle is towed with the ignition ON. (This is not a malfunction)

15. CARRIER CAR

Before lowering the vehicle from the carrier car, perform the following operations.

CAUTION:

Always perform the following operations before lowering the vehicle from the carrier car. Otherwise, the power unit will rotate reversely, which may cause the damage to the engine, vacuum pump, and transmission.

1. Start the engine.

2. Set the transmission shift position into driving direction of the vehicle. (When the vehicle drives forward, do not set the transmission into R range. When the vehicle drives rearward, do not set the transmission into 1 — 5 speed, or D range.)

CAUTION:

Be sure to perform 2) mentioned above even if the engine cannot be started in some reasons.

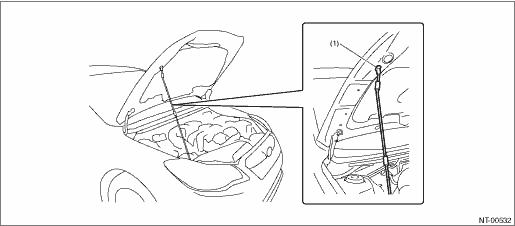

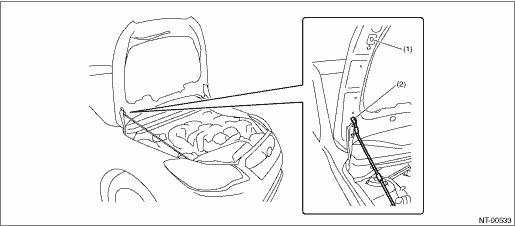

16. FRONT HOOD STAY

1. Always attach the stay to the normal position when performing works such as inspections and general maintenance.

CAUTION:

• During the inspection and general maintenance, always be sure to turn the ignition switch to OFF.

• At the inspection and general maintenance, do not detach the stay.

(1) | Normal attached position |

2. When wider front hood opening is necessary, set the stay to the lower position (hood hinge) as shown in the figure.

(1) | Normal attached position | (2) | Installation position at full open |

17. GENERAL SCAN TOOL

Using general scan tools will greatly improve the efficiency of repairing engine electronic throttle controls. Subaru Select Monitor can be used to diagnose the engine, VDC, air conditioner and other parts.

18. AWD CIRCUIT MEASURES

1. Full-time AWD MT model

Since viscous coupling (limited slip differential) is used in the center differential, cut-off of AWD circuit cannot be carried out.

2. Full-time AWD CVT model

Since electronically controlled MP-T hydraulic multi-plate clutch is adapted for center differential, switch to FWD by using Subaru Select Monitor.

19. SPEEDOMETER TEST

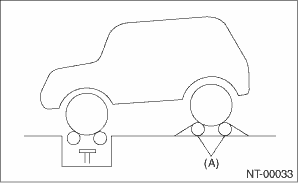

1. Rear wheel free roller system

(1) Set the free roller on the floor of rear wheel side securely according to the wheel base and rear tread of the vehicle.

(2) Let the vehicle ride on the tester and free roller gently.

CAUTION:

Fix the vehicle using a pulling metal (chain or wire) to the front and rear towing hooks or tie-down hook to prevent the lateral runout of front wheels and springing out of vehicle.

(A) | Free roller |

(3) Set the speedometer tester.

(4) Conduct the speedometer test work.

CAUTION:

Do not operate the clutch quickly and do not accelerate or decelerate suddenly during work.

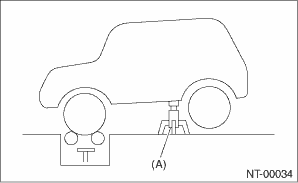

2. Rear wheel jack-up system

(1) Set the vehicle on speedometer tester.

CAUTION:

Fix the vehicle using a pulling metal (chain or wire) to the front and rear towing hooks or tie-down hook to prevent the lateral runout of front wheels and springing out of vehicle.

(2) Jack up the rear wheels and set the rigid racks to the specified locations of side sill.

(A) | Rigid rack |

(3) Conduct the speedometer test work.

CAUTION:

Do not operate the clutch quickly and do not accelerate or decelerate suddenly during work.

20. BRAKE TEST

1. Full-time AWD MT model

(1) Perform this test after driving the vehicle 2 to 3 km (1.24 to 1.86 miles) on road in order to stabilize the viscous torque of viscous coupling.

(2) Keep the front or rear wheels on the ground for this test.

NOTE:

Effect of the viscous torque on braking force will be added approx. 25 kg compared with FWD model.

Note

Note

...

Other materials:

Odometer

Type A

Trip knob

Type B

Trip knob (U.S.-spec. models)

Trip knob (except U.S.-spec. models)

This meter displays the odometer when

the ignition switch is in the "ON" position.

The odometer shows the total distance

that the vehicle has been driven.

If you press the trip knob ...

Rear wiring harness Location

WIRING SYSTEM > Rear Wiring HarnessLOCATIONConnectorConnecting toNo.PoleColorAreaNo.DescriptionR120C-1B97Bulkhead wiring harnessR320C-3B99R41BlackB-4 Parking brake switchR520C-3B92Bulkhead wiring harnessR93C-5 Front door switch LHR108B-5D22Rear door cord LHR123B-2 Front door switch RHR138B-3D28Re ...

Dtc b1577 imm control module eeprom

KEYLESS ACCESS WITH PUSH BUTTON START SYSTEM (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC B1577 IMM CONTROL MODULE EEPROM1. EXCEPT FOR C0 AND C5 MODELSDTC detecting condition:• Defective keyless access CM• When inaccessible to ROM in keyless access CM.STE ...