Subaru Crosstrek Service Manual: Installation

LUBRICATION(H4DO) > Oil Level Switch

INSTALLATION

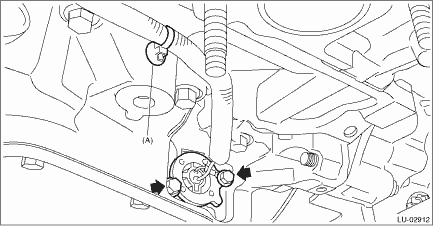

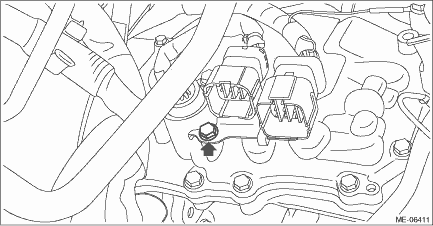

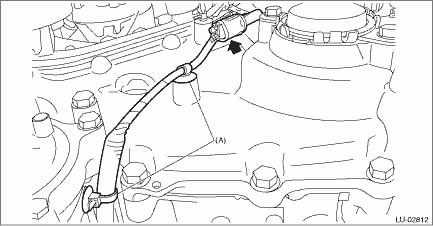

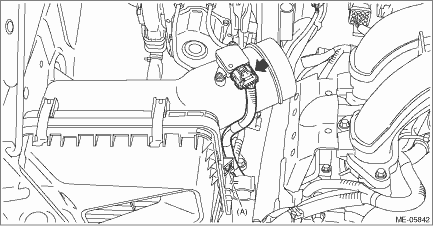

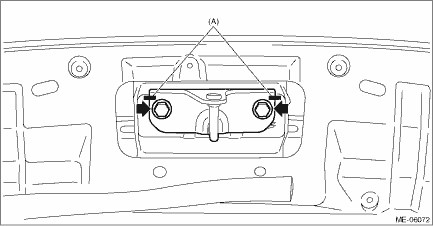

1. Install the oil level switch and the clip (A) to the oil pan upper.

NOTE:

• Use new O-rings.

• Apply a coat of engine oil to the O-rings.

Tightening torque:

6.4 N·m (0.7 kgf-m, 4.7 ft-lb)

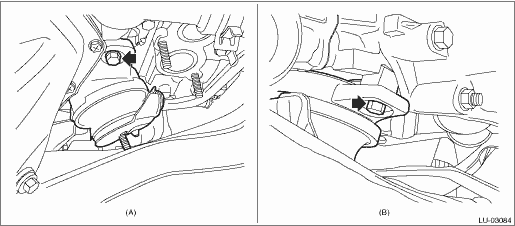

2. Install the engine mounting LH onto the engine.

Tightening torque:

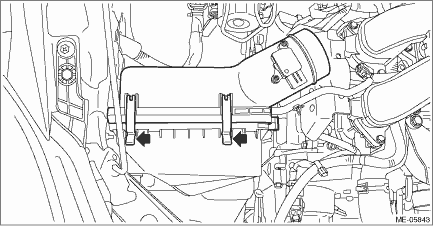

35 N·m (3.6 kgf-m, 25.8 ft-lb)

(A) | Front side | (B) | Rear side |

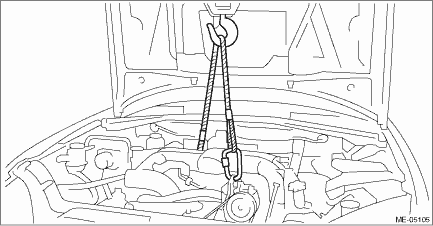

3. Lower the engine and remove the lifting device and wire ropes.

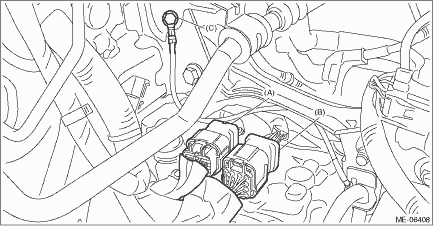

4. Remove the bolt and turn the transmission harness counterclockwise to install the transmission harness to the control valve body. (CVT model)

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

5. Install the bolt which holds the transmission harness stay. (CVT model)

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

6. Install the transmission case cover. (CVT model)

Tightening torque:

8 N·m (0.8 kgf-m, 5.9 ft-lb)

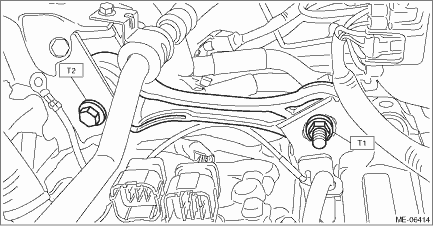

7. Install the pitching stopper.

Tightening torque:

T1: 50 N·m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N·m (5.9 kgf-m, 42.8 ft-lb)

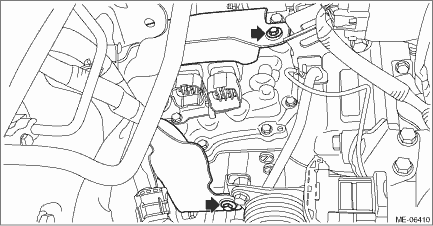

8. Connect the transmission radio ground terminal (C) to the vehicle body, and connect the bulkhead harness connector to the transmission harness connector (A) and the inhibitor harness connector (B). (CVT model)

Tightening torque:

13 N·m (1.3 kgf-m, 9.6 ft-lb)

9. Install the electric power steering gearbox. Electric Power Steering Gearbox > INSTALLATION">

10. Install the front drive shaft LH. Front Drive Shaft > INSTALLATION">

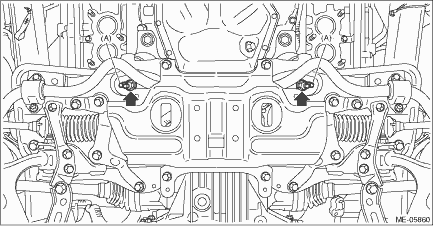

11. Install the nuts which hold the engine mounting to the front crossmember. (CVT model)

NOTE:

• Make sure that locators (A) of the engine mounting are securely inserted.

• Use a new nut.

Tightening torque:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

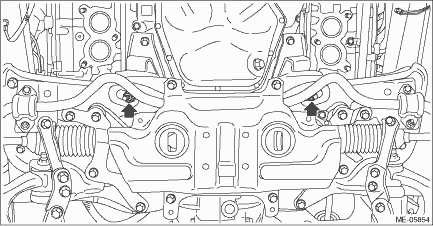

12. Install the nuts which hold the engine mounting to the front crossmember. (MT model)

NOTE:

Use a new nut.

Tightening torque:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

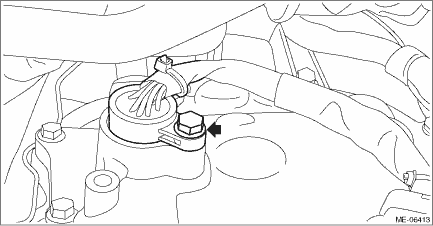

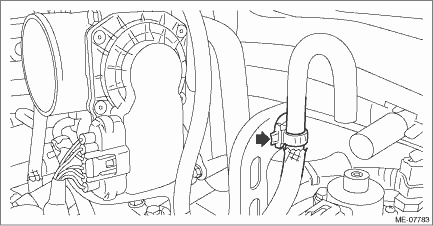

13. Connect the connector of oil level switch to the engine harness, and install the clip (A) securing the harness.

14. Install the front exhaust pipe. Front Exhaust Pipe > INSTALLATION">

15. Install the under cover.

16. Lower the vehicle.

17. Secure the air breather hose to the engine rear hanger using clip. (MT model)

18. Install the air intake case (rear).

19. Install the clip (A) which secures the air flow and intake air temperature sensor harness, and connect the connector to the air flow and intake air temperature sensor.

20. Install the air intake boot. Air Intake Boot > INSTALLATION">

21. Install the air intake duct. Air Intake Duct > INSTALLATION">

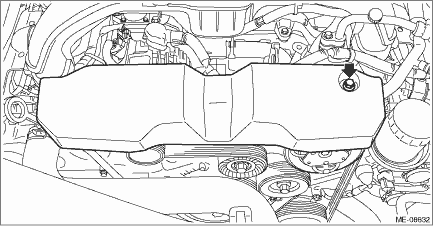

22. Install the V-belt cover.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

23. Refill the engine oil. Engine Oil > REPLACEMENT">

24. Connect the battery ground terminal. NOTE">

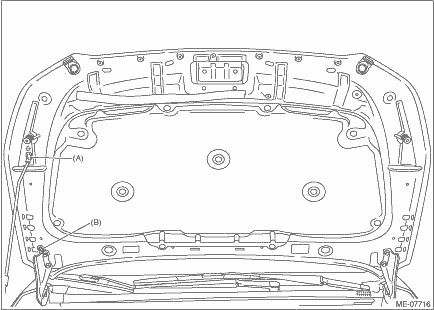

25. Change the front hood stay position from (B) to (A).

26. Install the front hood striker to the front hood by aligning the alignment marks (A), and close the front hood.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

Wiring diagram

Wiring diagram

LUBRICATION(H4DO) > Oil Level SwitchWIRING DIAGRAM• Engine electrical system Engine Electrical System > WIRING DIAGRAM">• CAN communication system CAN Communication System ...

Removal

Removal

LUBRICATION(H4DO) > Oil Level SwitchREMOVAL1. Open the front hood, and make alignment marks (A) on the front hood striker and the front hood using a marker pen.2. Remove the front hood striker from ...

Other materials:

Removal

CLUTCH SYSTEM > Clutch Disc and CoverREMOVAL1. Remove the transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Attach the ST on the flywheel.ST 499747100CLUTCH DISC GUIDE3. Remove the clutch cover and clutch disc.NOTE:• Take care not to allow oil ...

Hill start assist warning light does not come on

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Warning Light Illumination PatternHILL START ASSIST WARNING LIGHT DOES NOT COME ONDetecting condition:Defective combination meterTrouble symptom:When the ignition switch is turned to ON (engine OFF), hill start assist warning light does not illuminat ...

Component

BRAKE > General DescriptionCOMPONENT1. FRONT DISC BRAKE(A)Shim-separate brake pad type(B)Shim-integrated brake pad type (1)Caliper body(11)Pad clip - upper(19)Cap - bleeder(2)Bleeder - screw(12)Pad clip - lower (3)Guide pin - front brake (black)(13)Shim - disc brake front*1:17 mm (width a ...