Subaru Crosstrek Service Manual: Installation

EXTERIOR/INTERIOR TRIM > Instrument Panel Assembly

INSTALLATION

CAUTION:

• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “AIRBAG SYSTEM”. General Description > CAUTION">

• After installing the panel center assembly, check that the air vent grille of the panel center assembly is inserted correctly into the air vent duct.

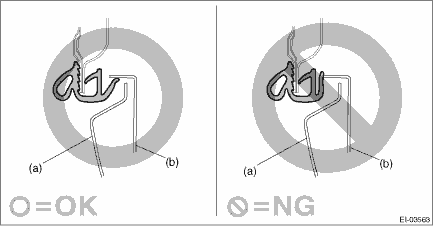

• When installing the cover - instrument panel side (a), make sure that the body side weather strip - flange front does not come inside the panel COMPL - instrument (b).

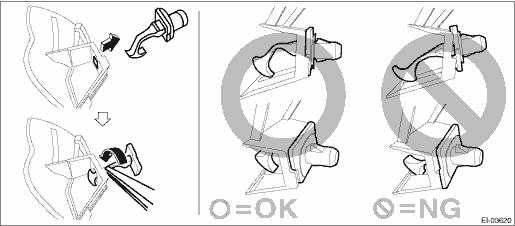

• When reusing the tether clip on the upper part of the trim panel - front pillar UPR, check that there is no damage to the tether clip. If the tether clip is damaged, always replace it with a new tether clip. If the tether clip is damaged, its holding force is reduced and the trim panel - front pillar UPR may come off.

• Do not reuse the tether clip removed from the upper part of the trim panel - front pillar UPR. Always replace with a new part.

• Check the installation status of the tether clips and install the trim panel - front pillar UPR.

1. Attach components until the instrument panel assembly is formed, in the reverse order of removal.

NOTE:

Method of installing insulator

• Adhesive

Use polyurethane adhesive. When assembling the instrument panel assembly, wait until the adhesive has evaporated to prevent filling of the smell in the compartment.

• Double-sided tape

Use commercial double-sided tape. (Use strong double-sided adhesive tape.)

2. Insert the matching pins on the body side (three locations - one in the center and the remaining two on both sides) into the instrument panel assembly and the beam COMPL - steering.

3. Check that the matching pins are inserted securely, and then route the harness.

4. Install the sunload sensor and the grille - front defroster.

5. Secure the instrument panel assembly and the beam COMPL - steering to the vehicle body.

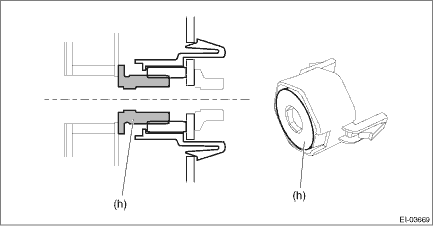

(1) Position the instrument panel assembly and the beam COMPL - steering to the vehicle body and tighten the adjuster - clip space.

Preparation tool:

Hexagon wrench: 8 mm (0.31 in)

NOTE:

Tighten so that there is no gap between the adjuster portion (h) and the body.

Tightening torque:

Adjuster - clip space: 0.8 — 4 N·m (0.08 — 0.41 kgf-m, 0.6 — 2.95 ft-lb)

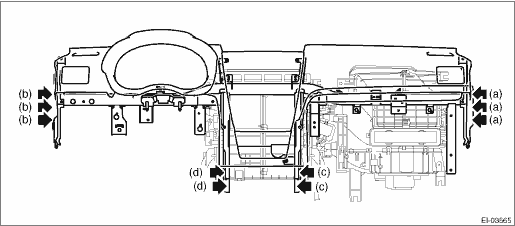

(2) Temporarily tighten the bolts (a), (b), (c) and (d) of the beam COMPL - steering.

(3) Tighten the beam COMPL - steering in the order from (a) to (d) to the specified torque.

Tightening torque:

Beam COMPL - steering: 25 N·m (2.55 kgf-m, 18.4 ft-lb)

Passenger’s airbag module: 7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

6. Install each part in the reverse order of removal.

Tightening torque:

Column assembly - steering: General Description > COMPONENT">

Knee airbag module: 7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

Console box assembly: 6.5 N·m (0.66 kgf-m, 4.8 ft-lb)

Removal

Removal

EXTERIOR/INTERIOR TRIM > Instrument Panel AssemblyREMOVALCAUTION:• Before handling the airbag system components, refer to “CAUTION” of “General Description” in “ ...

Other materials:

Dtc p1497 coil 3 egr "a" control circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P1497 COIL 3 EGR "A" CONTROL CIRCUIT HIGHNOTE:For the diagnostic procedure, refer to DTC P1499. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P1499 COIL 4 EGR "A" CONTRO ...

Clear memory mode Operation

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS) > Clear Memory ModeOPERATION1. On «Start» display, select «Diagnosis».2. On «Vehicle selection» display, input the vehicle information and select «Confirmed».3. On «Main Menu» display, select «Each System».4. On «Select System» display, s ...

Dtc p2747 intermediate shaft speed sensor "b" circuit no signal

CONTINUOUSLY VARIABLE TRANSMISSION (DIAGNOSTICS) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P2747 INTERMEDIATE SHAFT SPEED SENSOR "B" CIRCUIT NO SIGNALDTC detecting condition:Immediately at fault recognitionTrouble symptom:• Standing start problems• Shock o ...