Subaru Crosstrek Service Manual: Installation

DRIVE SHAFT SYSTEM > Rear Drive Shaft

INSTALLATION

1. Replace the rear differential side oil seal. Rear Differential Side Oil Seal > REPLACEMENT">

NOTE:

After pulling out the drive shaft assembly, be sure to replace with a new oil seal.

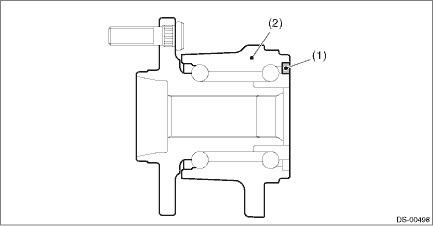

2. Insert the drive shaft assembly into the rear hub spline, and pull it into the specified position.

CAUTION:

• Be careful not to damage the magnetic encoder.

• Do not get closer the tool which charged magnetism to magnetic encoder.

• Do not hammer the drive shaft assembly when installing.

(1) | Magnetic encoder | (2) | Rear hub unit bearing |

3. Tighten the axle nut temporarily.

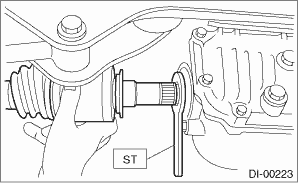

4. Using the ST, install the rear drive shaft assembly to the rear differential.

Preparation tool:

ST: OIL SEAL PROTECTOR (28099PA090)

5. Install the rear differential assembly to the rear sub frame assembly.

CAUTION:

Be sure to use a new self-locking nut.

Tightening torque:

Differential assembly — bushing - differential: 70 N·m (7.1 kgf-m, 51.6 ft-lb)

Differential assembly — rear sub frame assembly: 110 N·m (11.2 kgf-m, 81.1 ft-lb)

6. Install the sensor assembly - headlight beam leveler.

Tightening torque:

7.5 N·m (0.8 kgf-m, 5.5 ft-lb)

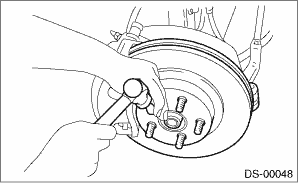

7. While pressing the brake pedal, tighten the new axle nuts to the specified torque.

CAUTION:

Do not load the rear axle before tightening the axle nut. Doing so may damage the hub unit bearing.

Tightening torque:

190 N·m (19.4 kgf-m, 140.1 ft-lb)

8. Lock the axle nut securely.

9. Fill differential gear oil.

10. Install the rear wheels.

Tightening torque:

Except for C4 model: 120 N·m (12.2 kgf-m, 88.5 ft-lb)

C4 model: 100 N·m (10.2 kgf-m, 73.8 ft-lb)

11. Perform reinitialization of the auto headlight beam leveler system. (Model with auto headlight beam leveler) Auto Headlight Beam Leveler System > PROCEDURE">

Inspection

Inspection

DRIVE SHAFT SYSTEM > Rear Drive ShaftINSPECTIONCheck the removed parts for damage, wear, corrosion etc. Repair or replace if defective.• DOJ (Double Offset Joint):Check for seizure, corrosion ...

Other materials:

Inspection

MECHANICAL(H4DO) > Cam CarrierINSPECTION1. Visually check the cam carrier filter, and if clogging is found, replace with a new part.2. Check the camshaft journals for damage and wear. Replace the camshaft if faulty.3. Check the cam face condition of camshaft, and remove the minor faults by grindi ...

Aluminum wheels

Aluminum wheels can be scratched and

damaged easily. Handle them carefully to

maintain their appearance, performance,

and safety.

When any of the wheels are removed

and replaced for tire rotation or to change

a flat tire, always check the tightness of

the wheel nuts after driving approx ...

ABS (Anti-lock Brake System)

The ABS prevents the lock-up of wheels

which may occur during sudden braking or

braking on slippery road surfaces. This

helps prevent the loss of steering control

and directional stability caused by wheel

lock-up.

When the ABS is operating, you may hear

a chattering noise or feel a slight v ...