Subaru Crosstrek Service Manual: Installation

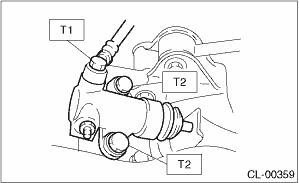

CLUTCH SYSTEM > Operating Cylinder

INSTALLATION

1. Install in the reverse order of removal.

NOTE:

• Before installing the operating cylinder, apply grease to the contact point of the release lever and operating cylinder.

Grease:

NICHIMOLY N-130 or equivalent

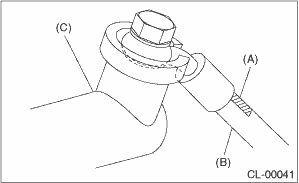

• Be sure to install the clutch hose with the mark side facing upward.

• Be careful not to twist the clutch hose during installation.

• Use a new gasket.

Tightening torque:

T1: 18 N·m (1.8 kgf-m, 13.3 ft-lb)

T2: 37 N·m (3.8 kgf-m, 27.3 ft-lb)

(A) | Mark |

(B) | Clutch hose |

(C) | Operating cylinder |

Tightening torque:

Air intake boot

3 N·m (0.3 kgf-m, 2.2 ft-lb)

2. After bleeding air from the operating cylinder, ensure that the clutch operates properly. Clutch Fluid Air Bleeding">

Inspection

Inspection

CLUTCH SYSTEM > Operating CylinderINSPECTION1. Check that the operating cylinder is not damaged. Replace the operating cylinder if it is damaged.2. Check the brake fluid leakage on the operating cy ...

Other materials:

Installation

MECHANICAL(H4DO) > Rocker CoverINSTALLATION1. ROCKER COVER RH1. Install the #1 spark plug pipe gasket and #3 spark plug pipe gasket to the #1 spark plug pipe and #3 spark plug pipe.NOTE:• Use a new #1 spark plug pipe gasket and #3 spark plug pipe gasket.• Apply a light coat of engine ...

Dtc b1908 short in front p/t lh (to +b)

AIRBAG SYSTEM (DIAGNOSTICS) > Diagnostic Chart with Trouble CodeDTC B1908 SHORT IN FRONT P/T LH (TO +B)Diagnosis start condition:Ignition voltage is 10 V to 16 V.DTC detecting condition:• Seat belt pretensioner (LH) circuit is shorted to power supply.• Pretensioner (LH) is faulty.&bul ...

Steering switches for audio

Some parts of the audio/visual system can

be adjusted using the switches on the

steering wheel.

+ − switch

switch

Mute/Enter switch

List switch

Back switch

Source switch

+/− switch

Mode

Operation

Function

Except list screen

Press

V ...