Subaru Crosstrek Service Manual: Inspection

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Shifter Fork and Rod

INSPECTION

1. Check the shifter fork and fork rod for damage. Replace if it is damaged.

2. Gearshift mechanism

Repair or replace the gearshift mechanism if excessively worn, bent or defective in any way.

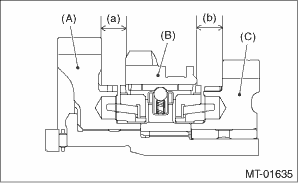

3. Inspect the clearance between 1st, 2nd driven gear and reverse driven gear. If any clearance is not within specifications, replace the shifter fork as required.

Clearance (a) and (b):

9.5 mm (0.374 in)

(A) | 1st driven gear |

(B) | Reverse driven gear |

(C) | 2nd driven gear |

1st-2nd shifter fork | ||

Part No. | Mark | Remarks |

32804AA060 | 1 | Approaches 1st gear by 0.2 mm (0.008 in). |

32804AA070 | No mark | Standard |

32804AA080 | 3 | Approaches 2nd gear by 0.2 mm (0.008 in). |

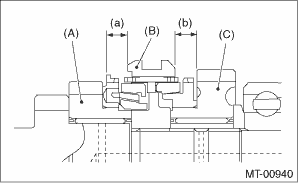

4. Inspect the clearance between the 3rd, 4th drive gear and the coupling sleeve. If any clearance is not within specifications, replace the shifter fork as required.

Clearance (a) and (b):

9.3 mm (0.366 in)

(A) | 3rd drive gear |

(B) | Coupling sleeve |

(C) | 4th drive gear |

3rd-4th shifter fork | ||

Part No. | Mark | Remarks |

32810AA061 | 1 | Approaches 4th gear by 0.2 mm (0.008 in). |

32810AA071 | No mark | Standard |

32810AA101 | 3 | Approaches 3rd gear by 0.2 mm (0.008 in). |

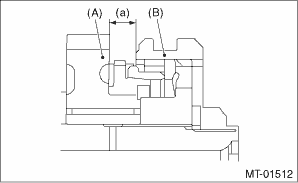

5. Inspect the clearance between 5th drive gear and coupling sleeve. If any clearance is not within specifications, replace the shifter fork as required.

Clearance (a):

9.3 mm (0.366 in)

(A) | 5th drive gear |

(B) | Coupling sleeve |

5th shifter fork | ||

Part No. | Mark | Remarks |

32812AA201 | 7 | Approaches 5th gear by 0.2 mm (0.008 in). |

32812AA211 | No mark | Standard |

32812AA221 | 9 | Moves away from 5th gear by 0.2 mm (0.008 in). |

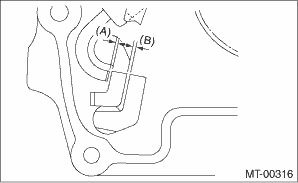

6. Inspect the rod end clearances (A) and (B). If any clearance is not within specifications, replace the fork rod or shifter fork as required.

Clearance (A):

3rd-4th — 5th

0.5 — 1.3 mm (0.020 — 0.051 in)

Clearance (B):

1st-2nd — 3rd-4th

0.4 — 1.4 mm (0.016 — 0.055 in)

Removal

Removal

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Shifter Fork and RodREMOVAL1. Remove the manual transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the ...

Other materials:

Removal

MANUAL TRANSMISSION AND DIFFERENTIAL(5MT) > Main Shaft AssemblyREMOVAL1. Remove the manual transmission assembly from the vehicle. Manual Transmission Assembly > REMOVAL">2. Remove the transfer case together with the extension case assembly. Transfer Case and Extension Case Assembly ...

Dtc p1493 coil 1 egr "a" control circuit high

ENGINE (DIAGNOSTICS)(H4DO) > Diagnostic Procedure with Diagnostic Trouble Code (DTC)DTC P1493 COIL 1 EGR "A" CONTROL CIRCUIT HIGHNOTE:For the diagnostic procedure, refer to DTC P1499. Diagnostic Procedure with Diagnostic Trouble Code (DTC) > DTC P1499 COIL 4 EGR "A" CONTRO ...

Transmission

SPECIFICATIONS > CrosstrekTRANSMISSION1. MTModel2.0 L DOHC non-turboTransmission type5MTClutch typeDSPDGear ratio1st3.5452nd1.8883rd1.2964th0.9725th0.780Rev.3.333Reduction gear (front)Type of gearHypoidGear ratio4.444Transfer reductionType of gearHelicalGear ratio1.000Reduction gear (rear)Final r ...